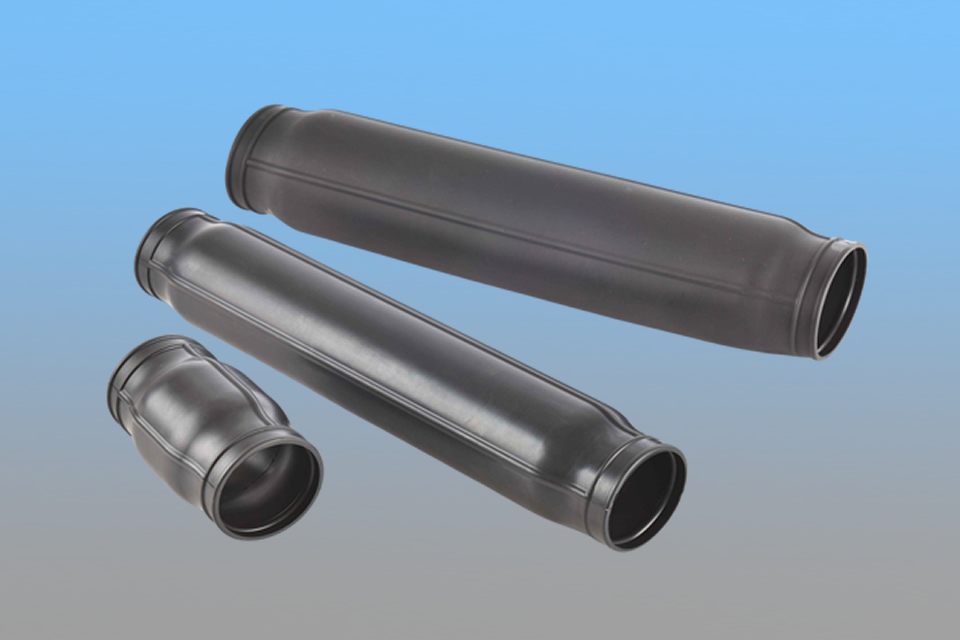

ESP bags

An electric submersible pump (ESP) is used in oil wells to pump fluids to the surface. This ESP system typically comprises a multi-staged centrifugal pump and a motor in an enclosed unit. Elastomer bags (ESP bags) can be used to protect components within the pump from their harsh operating environment.

The primary purpose of an ESP bag is to provide a positive barrier between the well fluids and the clean motor oil within, preventing any ingress of well fluid into the motor. These bags also act as an oil reservoir for the motor, and balance the internal pressure of the well fluid.

PPE packing elements are engineered to face the harsh operating conditions of upstream exploration and production applications.

More about ESP bags

ESP bags from PPE are manufactured from high performance elastomer materials which are proven against high temperatures and high pressures, and the required chemical resistance to well fluids.

For specific OEM requirements, PPE can undertake elastomer material development to meet test regimes and specifications. CO2 and H2S resistant elastomers are available.

PPE also offers engineered support to provide ESP bags in custom geometries, alongside manufacturing in various standard diameters to suit the most common casing sizes.

Key Attributes expand_more

- Available in elastomer material types: HNBR, FKM and Aflas® FEPM

- New elastomer material development available for specific OEM requirements

- Broad chemical resistance to well media

- Temperature capability up to 250°C (482°F)

- Various sizes and custom geometries available to meet the requirements of OEM pump manufacturers

- High quality manufacturing in USA and Europe to ISO 9001 & ISO TS 29001 accreditation

Benefits expand_more

- Optimizes operational performance and efficiency

- Increases pump performance and reliability

- Reduces chance of motor contamination and failure

- Maximizes pump life

Typical Applications expand_more

- Artificial lift for oil, water and brine well production

- Pipeline booster service

- Waterflood injection and gas well dewatering

- Steam injection and geothermal applications

View our range of high performance materials

Find your nearest sales contact

Resources

Take a look at some helpful resources to support you in identifying your optimal sealing solution.

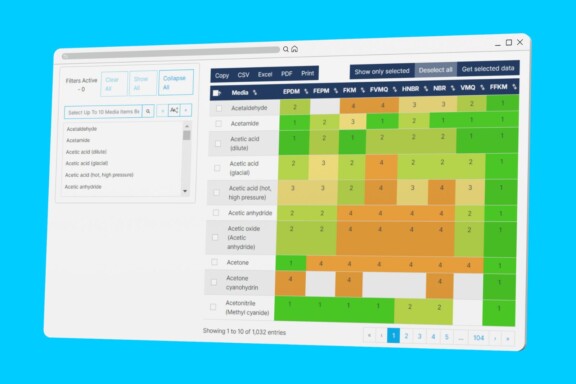

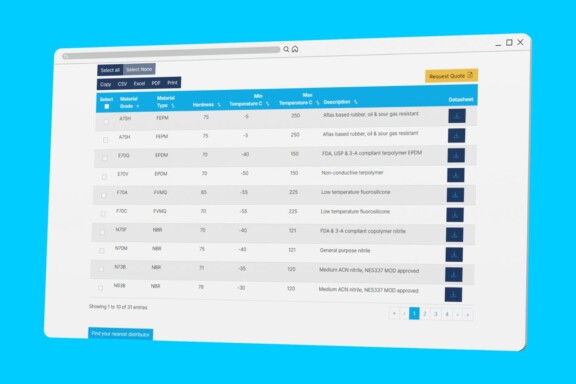

Elastomer Compatibility & Rubber Chemical Resistance Guide

PPE material grades selection tool

Video-Webinar library

Why do O-rings fail

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.