T-Seals

T-seals offer an excellent sealing solution for static or reciprocating dynamic applications. They can be designed to retro fit into existing O-ring grooves (both piston and rod orientations) or optimized for specific application requirements.

T-seals comprise of an elastomer T-shaped cross section and two backup rings made from an engineering grade plastic, often PTFE or PEEK.

The use of the backup rings allows the T-seal to be used in high pressure applications whilst still maintaining high sealing efficiency at low pressures. The design of the T-seal uses the system pressure to actively energize the backup rings. This ensures efficient extrusion resistance in single and bi-directional pressure applications, both in static and dynamic conditions.

Installation procedures are often simplified over other seal designs due to their symmetrical geometry.

PPE materials for T-seals

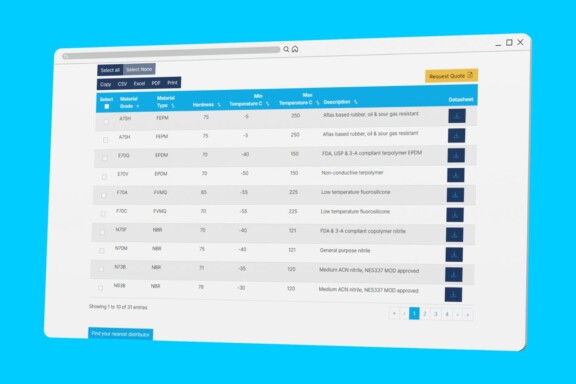

T-seals can be produced in the following high performance material types:

Perlast

expand_moreThe ultimate perfluoroelastomers for sealing applications where chemical resistance and high temperature performance are critical.

Perlast ICE

expand_moreThe ultimate perfluoroelastomers (FFKM) for sealing applications where chemical resistance and extreme low temperature performance are critical.

EnDura

expand_moreThe ultimate range of elastomers for sealing applications in the world’s most aggressive high pressure environments.

View our range of high performance materials

Find your nearest sales contact

Resources and Tools header

Take a look at some of our PPE resources to help you identify the most effective combination of material and profile for your sealing requirements.