Case Studies

Detailed below are some application stories based on recent projects.

Next day seals for critical O&G ball valves

A major offshore gas producer in the North Sea required immediate replacement of ball valve sealing components on an HP gas compression line.

Rapid response and OTD keeps F1 team on schedule

One of the world’s foremost Formula 1 racing teams required a high specification sealing solution ahead of their 2012 season.

Custom Designed Seal for Critical Life Science Application

Human genome research company required a 'make or break' seal in the flow cell manifold, to avoid any further contamination.

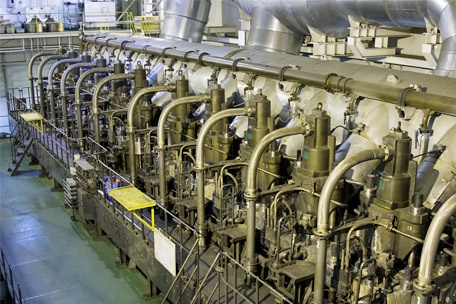

Fuel Injection Valves

Leading marine diesel manufacturer was experiencing unplanned dry docks costing £100,000 per day, as a result contact PPE to design and manufacture reliable FKM seal that would stand the test of time.

Steam Resistant Seal Material Protects Performance and Saves Cost

Leading manufacturer of valves used in high value biomedical and pharmaceutical processing and production facilities were experiencing bacterial contamination from current elastomer grade VCT95.

Life science development project kept on track by PPE seals

A leading OEM based in Japan developing high pressure liquid for transportation system for the medical and life science industry required elastomer seals that could perform under challenging pressure of 250 MPa (36,000 psi).

Improving ED cycles and safety on reciprocating compressors

Three North Sea floating platforms faced closure due to gas leaks on reciprocating compressors. Could PPE keep the platforms open with the correct choice of sealing material and geometry?

Critical oil and gas seals made, tested and delivered in four hours

A blue chip oil and gas company urgently required O-rings, PTFE ball seats and PEEK wear seats for high temperature valves on an offshore platform.

Increasing uptime on pharmaceutical filling and packaging lines

A global leader in pharmaceutical research and manufacture undertook a review of sealing on equipment using on a single Topicals filling and packaging line. PPE consulted on this review, proposing several operational improvements.

German dairy deploys Detectaseal to improve hygienic processing

Concerned about the risk of rubber seal contamination, a dairy in Germany has replaced its NBR elastomer seals in stainless steel pipework connections with Detectaseal® metal detectable seals.

Perlast seal extends life of vacuum discharge ball segment valve

Customers experiencing low seal lifetimes with EPDM materials on discharge ball valves are finding the chemical resistance of Perlast® offers an excellent alternative.

Rapid response on Sikorsky Black Hawk components

PPE designed, manufactured and tested a selection of seals for the iconic Sikorsky UH-60 Black Hawk helicopter, providing a more cost-effective and timely alternative.

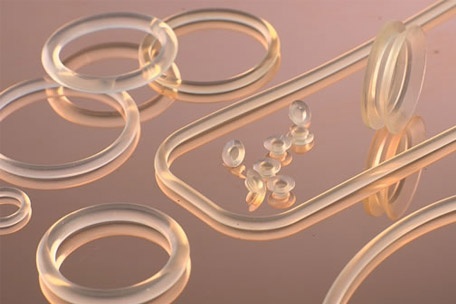

Innovative micro seal kits for lab equipment

PPE has developed a micro seal production technique which replaces individual seal elements with a web of seals, each linked by an ultra-thin membrane.

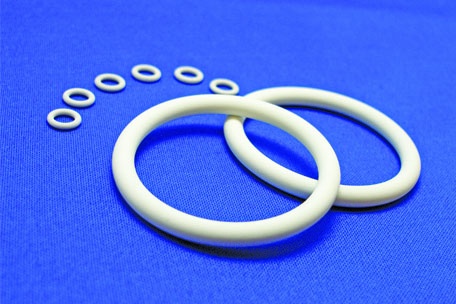

Perlast stem seals double operational life in ball valve

A leading Danish valve manufacturer supplying and servicing valves and instruments for control and measurement in industrial processes required high performance steam seals.

PPE seals expand ball valve offering for hot steam applications

Austrian ball valve manufacturer required high temperature sealing solution to encourage new business opportunities.

Composite piston seals deliver 4.5 times better maintenance cycles

A new approach to the design of piston seals in a food process application resulted in a large improvement in the reliability of the component, and the efficiency of the process line.

PPE helps Lufthansa Super Star Fly again

Reinforced diaphragm for use in breaking system of vintage L1469A “Super Star” aircraft required to restore it to an airworthy condition.

Material selection and seals manufactured to order; all in less then 2 weeks

A global exploration and production company focusing on Upstream applications kept experience seal failure with standard FKM elastomer.