Aerospace & Defence

Precision Polymer Engineering is a JOSCAR and Nadcap accredited, AS9100 Rev.D certified designer and manufacturer of high performance aerospace seals

In addition to O-rings or custom profiles for aerospace sealing requirements, PPE manufactures NES 337 seals for critical naval defence applications.

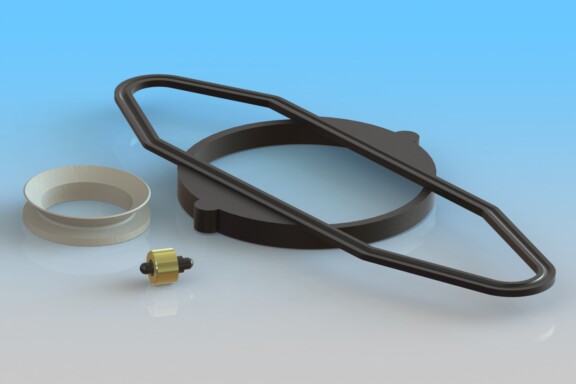

PPE manufactures bespoke sealing components for:

Military and civilian aircraft

Helicopters

Ships and Submarines

Gun Systems

PPE supplies O-rings, custom moldings, and other seal geometries to the entire aerospace supply chain.

We hold many prime contractor and OEM quality approvals. Our short lead times make us an ideal partner for Maintenance Repair and Overhaul (MRO) events, reacting quickly to aircraft-on-ground (AOG) situations to get your aircraft back in operation faster.

Custom Seals

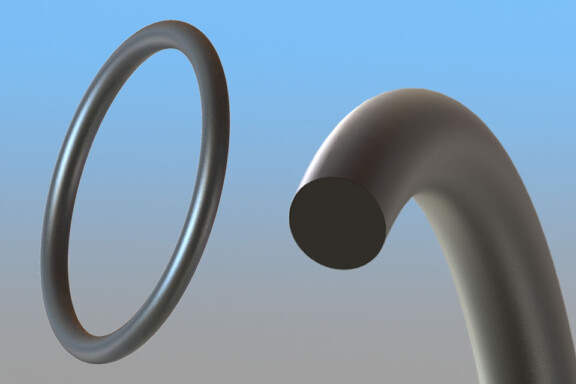

Elastomer O-Rings

Naval Defence – NES 337 O-rings and Seals

For naval equipment, PPE offers a complete range of Def. Stan. 02-337 (NES 337) materials accepted by the UK Ministry of Defence, for use on surface ships, submarines, and their associated systems and equipment.

Typical system applications include hydraulics, lubrication systems, fuel systems, and pneumatics.

Click below for details on PPE materials accepted for use under NES 337.

Certifications for Aerospace Seals

Take a look at some of our key approvals required for supply into the aerospace and defence sectors.

NES337 Defence

FAQs

What is an aerospace O-ring? expand_more

O-rings in aerospace applications are used to prevent leakage in shafts and cylindrical components, and to prevent environmental contaminants entering the seal assembly and cross-contamination of fluids within the assembly.

Aerospace O-rings can also be used to reduce friction between mating surfaces.

These critical roles make the correct material specification very important, with resistance to temperature extremes and chemical environments among the key attributes required from an aerospace seal.

What material should aerospace seals be made from? expand_more

Seals used in the aerospace industry have to deliver high performance with high reliability, and as such they have to be manufactured from specialised materials.

Some elastomer materials can retain excellent sealing effect under extreme temperatures and pressures, and against exposure to aggressive chemicals.

Depending on the environment, silicones, EPDMs, and fluorinated polymers like FKM can be good candidates for an aerospace O-ring, gasket, or custom component.

However, for full peace of mind in any operating environment, perfluoroelastomers (FFKMs) like Perlast® combine peak performance and reliability.

What conditions do aircraft seals have to withstand? expand_more

In critical applications where seal failure puts life at risk, such as aviation, the right material specification is critical.

Aerospace seals have to withstand high and low temperature extremes, high pressures, and the risk of chemical degradation from aggressive hydrocarbons and de-icing and cleaning agents.

In such environments, elastomer seals made from perfluorocarbons (FFKMs) offer the best long term sealing performance and the lowest cost of ownership.

Need more help? Speak to one of our experts today.

Looking for more technical detail? Check out our Resources & Tools.

Resources for Aerospace Seals

Browse some of our key resources relating to sealing for critical aerospace applications.

- WATCH: ‘Perlast and the value of a technical sealing partner’, with Stuart Campton (Strategic Market Development Leader, Fluorinated Products)

- WATCH: ‘Perlast and regulatory compliance’, with Jon Riley (Product Manager, Fluorinated Products)

- PPE ANIMATION: ‘How can total cost of ownership save you money?’