Micro Seals

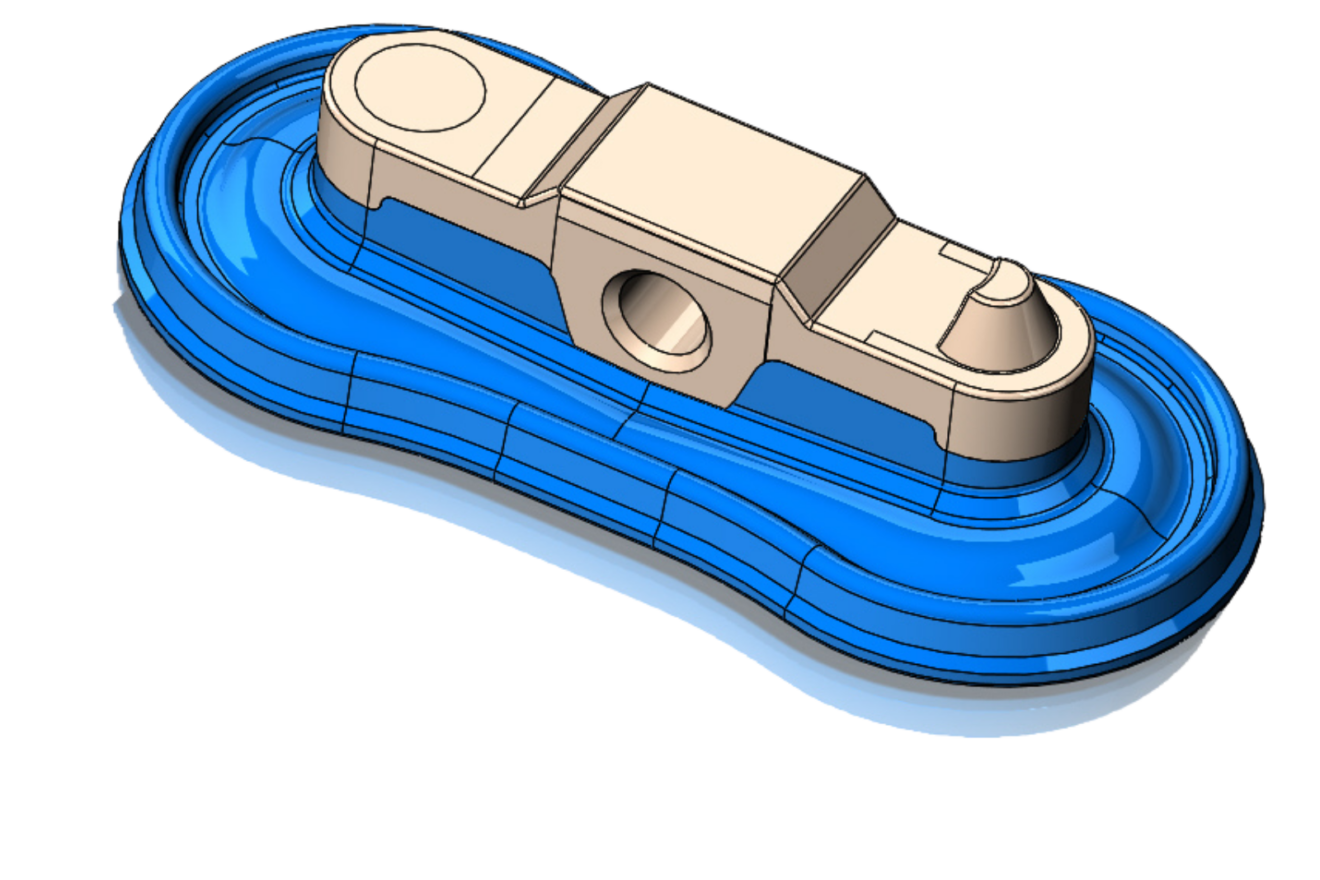

Micro seals are micro sized elastomer parts that require the highest degree of precision and quality to solve industry’s most critical applications.

Customize | Optimize | Minimize

Precision Polymer Engineering operates at the forefront of elastomer molding technology. MicroFORM® – PPE’s range of specialist small scale seals for critical applications and industries – are manufactured from high performance materials developed to seal effectively and reliably. These products are manufactured in a fully automated, ISO Class 6 clean room production environment, to minimise contamination risk.

Whatever the sealing challenge, our specialist sealing engineers are on hand to manufacture the right seal for you.

“Our Perlast® FFKM duckbill valves are clean, consistent & reliable. The valves have passed 2 million cycles, and I’m confident they will pass another 1 million.”

Quality Engineering Manager

Manufacturer of solenoid valves & precision pumps for high purity fluids

Industries & Applications

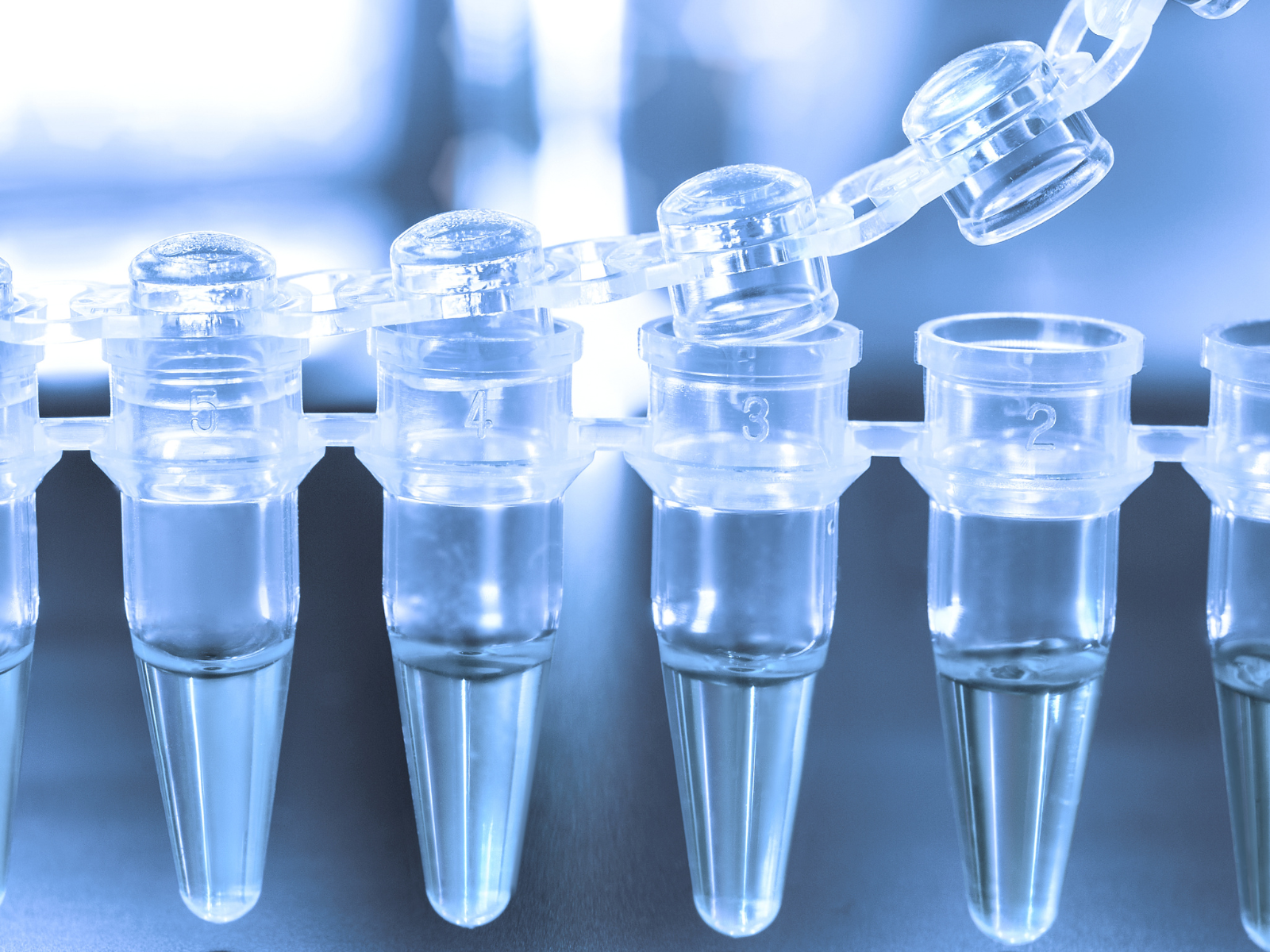

Pharmaceutical & Biomedical expand_more

A wide range of industries and applications rely on MicroFORM®, Precision Polymer Engineering’s range of custom-engineered seals for micro applications.

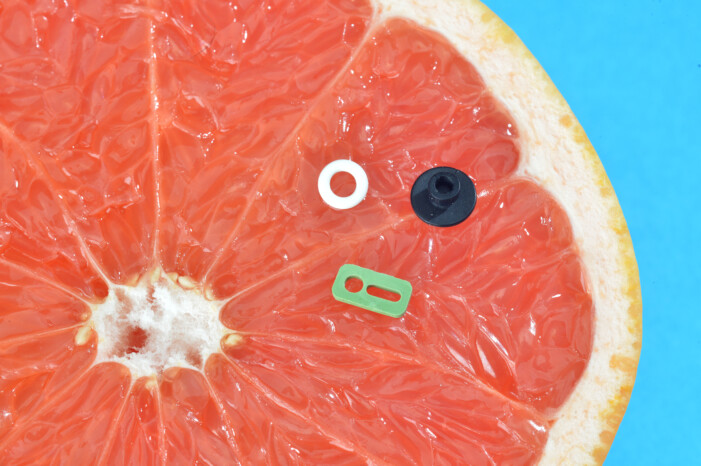

Applications include:

- Microfluidic Flow Control and Dispensing: Micro pumps, LOC connectors, micro reactors, miniaturized diagnostic equipment, pipettes, probes and precision syringes.

- Analytics: Mass spectrometer, chromatogram, gene synthesisers

- Measurement Instrumentation: Pressure/temperature/monitoring sensors, mass flow meters & controllers, pressure meters

Semiconductor expand_more

Seals in semiconductor processing applications need to perform reliably in high temperatures and chemically aggressive environments. Selecting the correct profile and material is crucial to ensure operations are not compromised.

MicroFORM® is available for semiconductor applications including: ![]()

- Wafer Handling: Process tools, end effector pads

Materials for Micro Seals

Material Types expand_more

PPE’s team of material scientists have developed a wide portfolio of materials for effective sealing in these particular environments. These materials are designed to handle the most challenging of thermal, chemical, and mechanical stresses, keeping equipment downtime to an absolute minimum.

Available elastomer materials include EPDM, FKM and FFKM – represented by PPE’s Kimura®, Perlast®, Perlast® ICE and EnDura® brands.

Compliance expand_more

PPE’s selection of MicroFORM® seals are certified compliant with FDA, USP Class VI, 3A 18-03, WRAS and EC1935-2004.

This ensures suitability for life science applications including pharmaceutical processing, and safeguards the safety of both operators and end consumers.

Capability expand_more

- High temperature capability up to +350°C (+662°F)

- Low temperature capability down to -60°C (-76°F)

- Almost universal chemical resistance (FFKM)

The Perlast family of FFKMs have been designed to deliver exceptional sealing performance under extreme temperatures and virtually all chemical operating environments. Combined with outstanding mechanical properties, these materials are the go-to when seal failure is not an option.

PPE Materials

PPE can manufacture sealing solutions for micro applications in the following elastomer material types:

Perlast®

expand_moreThe ultimate perfluoroelastomers for sealing applications where chemical resistance and high temperature performance are critical.

Kimura®

expand_moreA unique range of fully organic elastomers ideally suited to thermal, dynamic and specific plasma processes where radical concentrations are generally lower or where inorganic filler systems are undesirable.

Nanofluor®

expand_moreNanofluor® elastomers can be considered as hybrid materials, bridging a gap between the low cost of fluoroelastomer (FKM) and high cost of perfluoroelastomer (FFKM) polymer types.

EnDura®

expand_moreThe EnDura® range of elite elastomer materials has been specifically developed by PPE for use in downhole, surface and subsea oilfield equipment and offers excellent Explosive Decompression (ED) or Rapid Gas Decompression (RGD) resistance. The range includes material grades that provide the ultimate in chemical resistance and low temperature performance for use in Arctic conditions.

Resources for Micro Seals

Discover our most relevant resources and downloads, to help you optimise the performance and reliability of your sealing solution.

- Brochure: MicroFORM

WATCH: Our full range of explainer videos, animations and webinars on high performance sealing

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.