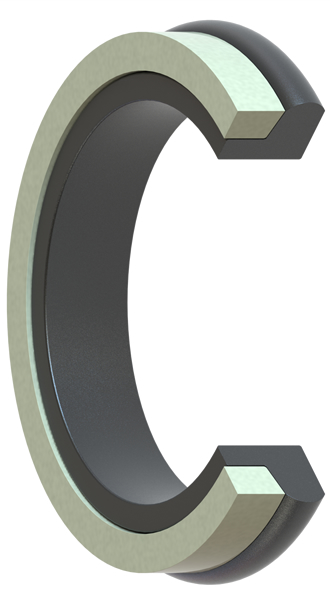

L-Seals

L-seals offer a cost effective alternative to T-seals for static or reciprocating dynamic applications, where high gland fill may be a concern with T-seals.

An L-seal can be designed to retro fit into existing O-ring grooves – both piston and rod orientations – or optimized for specific application requirements.

Similarly to T-seals, L-seals comprise of an elastomer L-shaped cross section using a single backup ring made from an engineering grade plastic, often PTFE or PEEK.

The use of the backup ring allows the L-seal to be used in high pressure applications whilst still maintaining high sealing efficiency at low pressures. The design of the L-seal uses the system pressure to actively energize the backup ring, ensuring efficient extrusion resistance in single direction pressure applications in static and dynamic conditions.

View our range of high performance materials

Find your nearest sales contact

Resources for L-seals

PPE has a wide selection of tools and resources available to help you get the best level of performance and reliability from your sealing solution. Take a look…

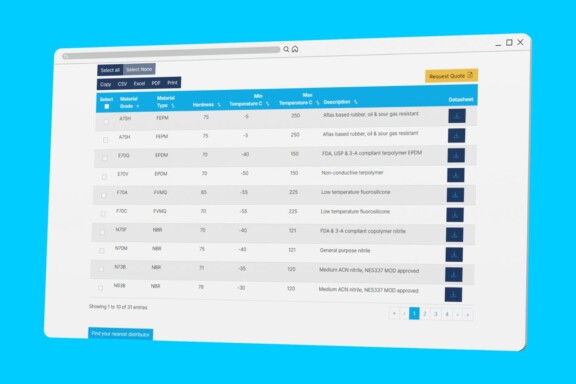

PPE material grades selection tool

Elastomer materials A-Z

Video-Webinar library

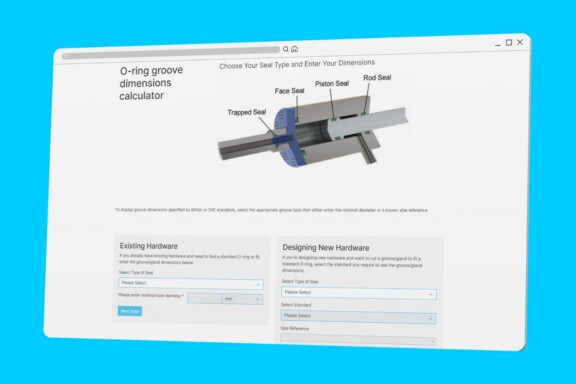

O-ring groove dimensions calculator

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.