EnDura® elastomers

The EnDura® range of elite oilfield elastomers has been specifically developed by PPE for use in downhole, surface and subsea oilfield equipment.

EnDura® offers excellent Explosive Decompression (ED) or Rapid Gas Decompression (RGD) resistance. The range includes material grades that provide the ultimate in chemical resistance and low temperature performance for use in Arctic conditions.

Key attributes

EnDura® has been developed for high performance sealing in critical energy applications. The materials in the EnDura® family are engineered to handle these rigorous thermal, chemical, and mechanical challenges.

Here are some key operational advantages:

Rapid Gas Decompression resistant

Rapid Gas Decompression resistant

Low temperature capability

Low temperature capability

High mechanical strength

High mechanical strength

Chemical resistance

Chemical resistance

EnDura® grades are tested to international RGD standards, such as:

- TOTAL GS PVV 142

- NORSOK M710 Annex B

- NACE TM0297

- ISO 23936-2

Sudden decompression events can lead to catastrophic seal failure with inferior sealing materials. EnDura® has been engineered to provide sustained resistance to RGD, which:

- Increases seal life expectancy and integrity

- Increases productivity through reduced maintenance and downtime

- Improves the integrity of oilfield equipment, keeping your operators safer

EnDura® elastomers provide low temperature sealing capability down to -51°C (-60°F) and up to +250°C (+482°F)

Excellent mechanical strength is vital for oilfield seals, where durability, safety, and reliable sealing performance are critical for operators – and a failed seal can have severe economic and environmental consequences.

EnDura® seals can withstand HPHT environments without deformation, cracking, or extruding. They have also been developed to withstand the abrasion associated with oilfield equipment moving parts, including sand, mud and rock particles.

With better elastic recovery and fatigue resistance, EnDura® gives operators the confidence that any unscheduled downtime associated with their sealing system will be kept to an absolute minimum.

EnDura® elastomers have better chemical resistance than conventional RGD resistant grades and are compliant with many international standards for sour gas (H2S) resistance.

• NACE TM0187

• NORSOK M710 Annex A

Rapid Gas Decompression resistant expand_more

Rapid Gas Decompression resistant expand_more

EnDura® grades are tested to inte ational RGD standards, such as:

- TOTAL GS PVV 142

- NORSOK M710 Annex B

- NACE TM0297

- ISO 23936-2

Sudden decompression events can lead to catastrophic seal failure with inferior sealing materials. EnDura® has been engineered to provide sustained resistance to RGD, which:

- Increases seal life expectancy and integrity

- Increases productivity through reduced maintenance and downtime

- Improves the integrity of oilfield equipment, keeping your operators safer

Low temperature capability expand_more

Low temperature capability expand_more

EnDura® elastomers provide low temperature sealing capability down to -51°C (-60°F) and up to +250°C (+482°F)

High mechanical strength expand_more

High mechanical strength expand_more

Excellent mechanical strength is vital for oilfield seals, where durability, safety, and reliable sealing performance are critical for operators – and a failed seal can have severe economic and environmental consequences.

EnDura® seals can withstand HPHT environments without deformation, cracking, or extruding. They have also been developed to withstand the abrasion associated with oilfield equipment moving parts, including sand, mud and rock particles.

With better elastic recovery and fatigue resistance, EnDura® gives operators the confidence that any unscheduled downtime associated with their sealing system will be kept to an absolute minimum.

Chemical resistance expand_more

Chemical resistance expand_more

EnDura® elastomers have better chemical resistance than conventional RGD resistant grades and are compliant with many inte ational standards for sour gas (H2S) resistance.

• NACE TM0187

• NORSOK M710 Annex A

Why choose PPE for oilfield elastomers?

Beyond the elastomer material itself, working with PPE also adds value in a number of ways at all stages in the design process and for on-going procurement.

- Expert technical support both before and after sale

- Design advice to optimize the seal design for the intended operating conditions

- Unrivalled rapid manufacturing lead-times

- Flexible and responsive manufacturing based on a cell-based operating model

- Global sales and support coverage

High performance elastomers for the highest pressure environments

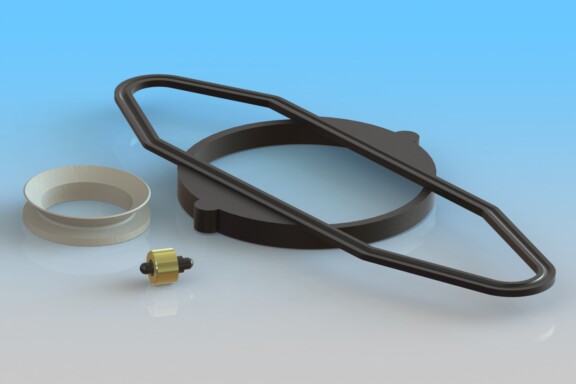

EnDura® products

We provide a wide selection of sealing solutions available in EnDura® elastomers, which are manufactured exclusively by PPE, for some of the most challenging, high pressure sealing applications in the world.

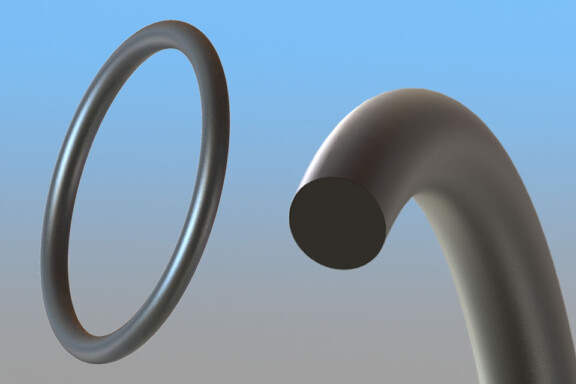

Elastomer O-Rings

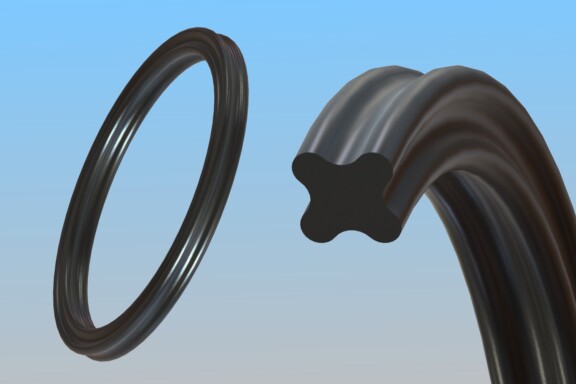

X-Rings Quad Rings

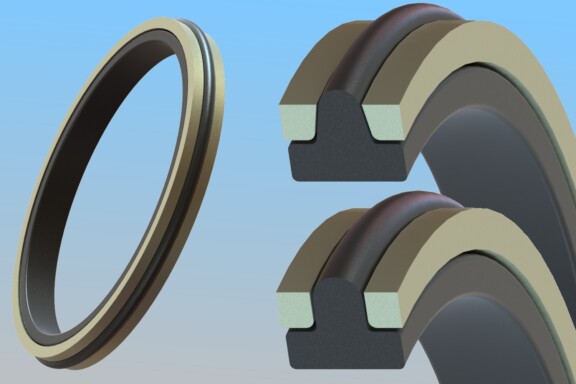

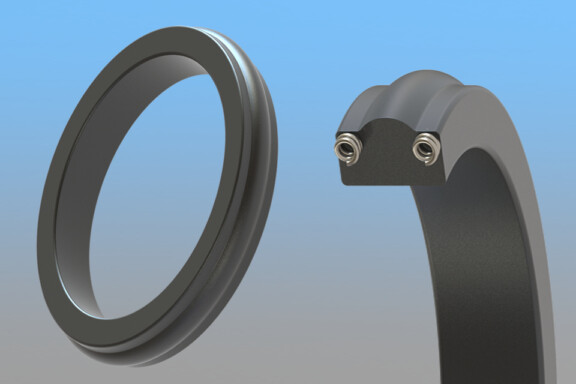

T-Seals

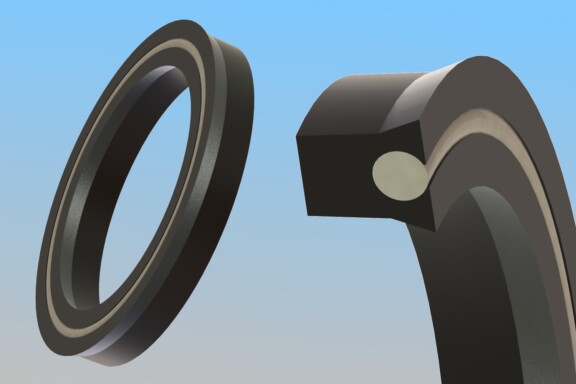

Lip Seals

Spring Seals

FS Seals

Metal End Cap Seals

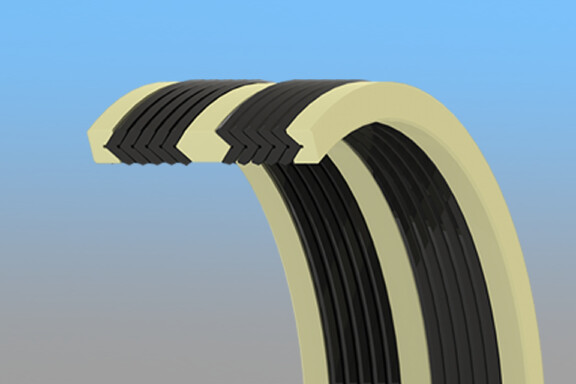

Chevron Stacks

Custom Seals

Resources

Below are some of our most popular downloads relating to EnDura® materials.

If you require further information on any sealing topic, please check out the Resources section of this website.

- Brochure: EnDura® elastomers

- Brochures: Explosive Decompression and Sour Gas

- Webinar: Low temperature sealing with elastomers in sour gas

Looking for more technical detail? Check out our Resources & Tools.

Need more help? Speak to one of our experts today.

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.

Find your nearest sales contact

We're here to create the perfect sealing solution for you…