Lip Seals

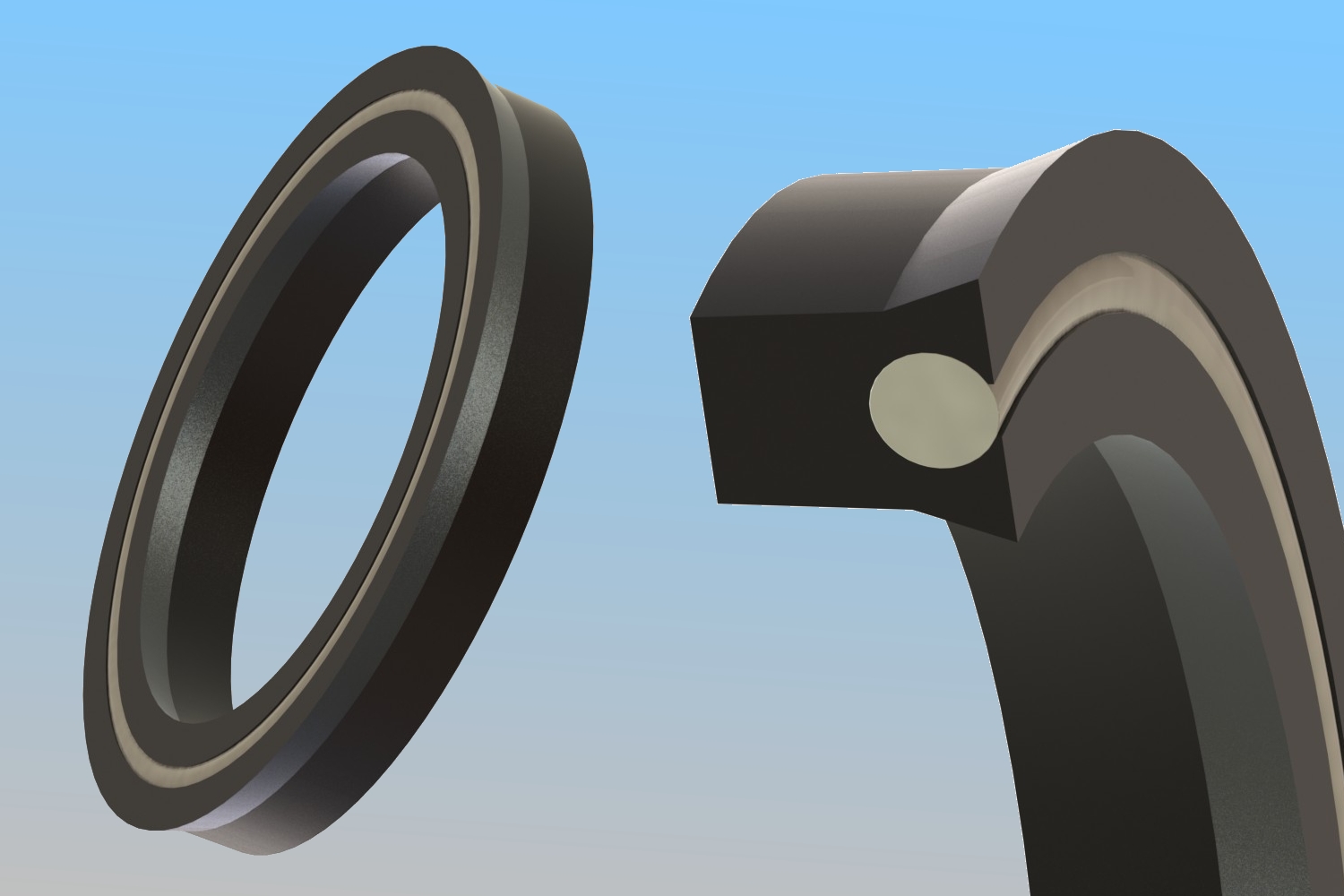

Energized lip seals comprise of a high modulus elastomer (or high grade engineering plastic) jacket, and a low modulus elastomer O‑ring energizer.

The low modulus O‑ring energizes the jacket under low pressure conditions to increase the sealing force allowing them to be used in low and high pressure applications.

PPE offers energized lip seals in a variety of profiles to suit your application – or enquire about our custom component design service.

About energized lip seals

Energized lip seals provide a versatile sealing system for uni‑directional pressure applications in either static or reciprocating dynamic conditions. Energized lip seals are symmetric in their cross section and so they can be used in both rod or piston grooves. Backup rings can be used in conjunction with energized lip seals to enhance extrusion resistance.

There are various profiles of energized lip seals available with differing qualities depending on application requirements.

PPE material brands

PPE’s range of energized lip seals can be produced in the following material types:

Perlast perfluoroelastomers

expand_moreThe ultimate perfluoroelastomers for sealing applications where chemical resistance and high temperature performance are critical.

Perlast® ICE

expand_moreThe ultimate perfluoroelastomers (FFKM) for sealing applications where chemical resistance and extreme low temperature performance are critical.

EnDura®

expand_moreThe ultimate range of elastomers for sealing applications in the world’s most aggressive high pressure environments.

View our range of high performance materials

Find your nearest sales contact

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.