Spring Seals

Spring seals, also known as S-seals and all-in-one T-seals, comprise of a high modulus elastomer and two integrated anti-extrusion springs. They are used to effectively seal applications that are subject to:

- Chemical attack by oilfield media

- Large clearance gaps

- High pressure (bi-directional)

- Remote hardware makeup

- Restricted access for seal installation

They provide a versatile sealing system for bi-directional pressure applications in static conditions. Commonly used in place of T-seals, S-seals are much easier to install, especially in ROV and restricted access situations. Additionally, with symmetrical cross sections they can be used in both rod or piston grooves.

Spring seals can be manufactured in various standard or non-standard sizes allowing them to be retro-fitted into existing O-ring grooves.

Materials for Spring Seals

PPE spring seals are available in unique combinations of elastomer materials not found elsewhere.

- Elastomers: HNBR, EnDura® FKM and Perlast® plus Perlast® ICE FFKM

- Springs: PEEK, Inconel Alloy or Stainless Steel 316

PPE material brands

Spring seals can be produced in the following material types, for performance and reliability in any application.

Perlast perfluoroelastomers

expand_moreThe ultimate perfluoroelastomers for sealing applications where chemical resistance and high temperature performance are critical.

Perlast® ICE

expand_moreThe ultimate perfluoroelastomers (FFKM) for sealing applications where chemical resistance and extreme low temperature performance are critical.

EnDura®

expand_moreThe ultimate range of elastomers for sealing applications in the world’s most aggressive high pressure environments.

Resources and Tools

Take a look at some of our PPE resources to help you identify the most effective combination of material and profile for your sealing requirements.

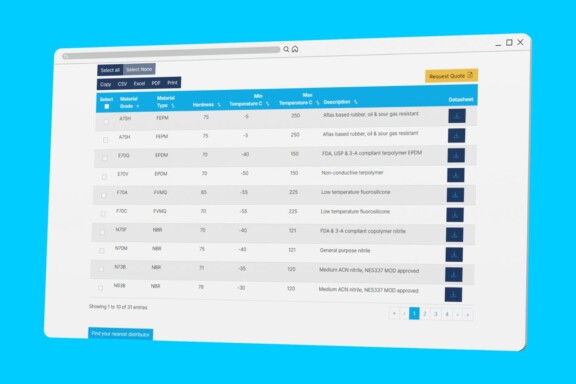

PPE material grades selection tool

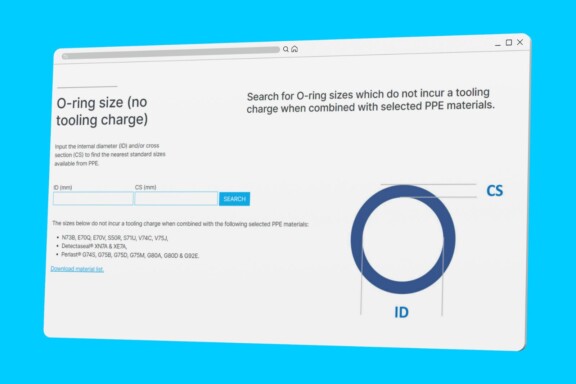

O-ring size (no tooling charge)

Request a quote

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.