Plasma Processes

Plasma Process Applications

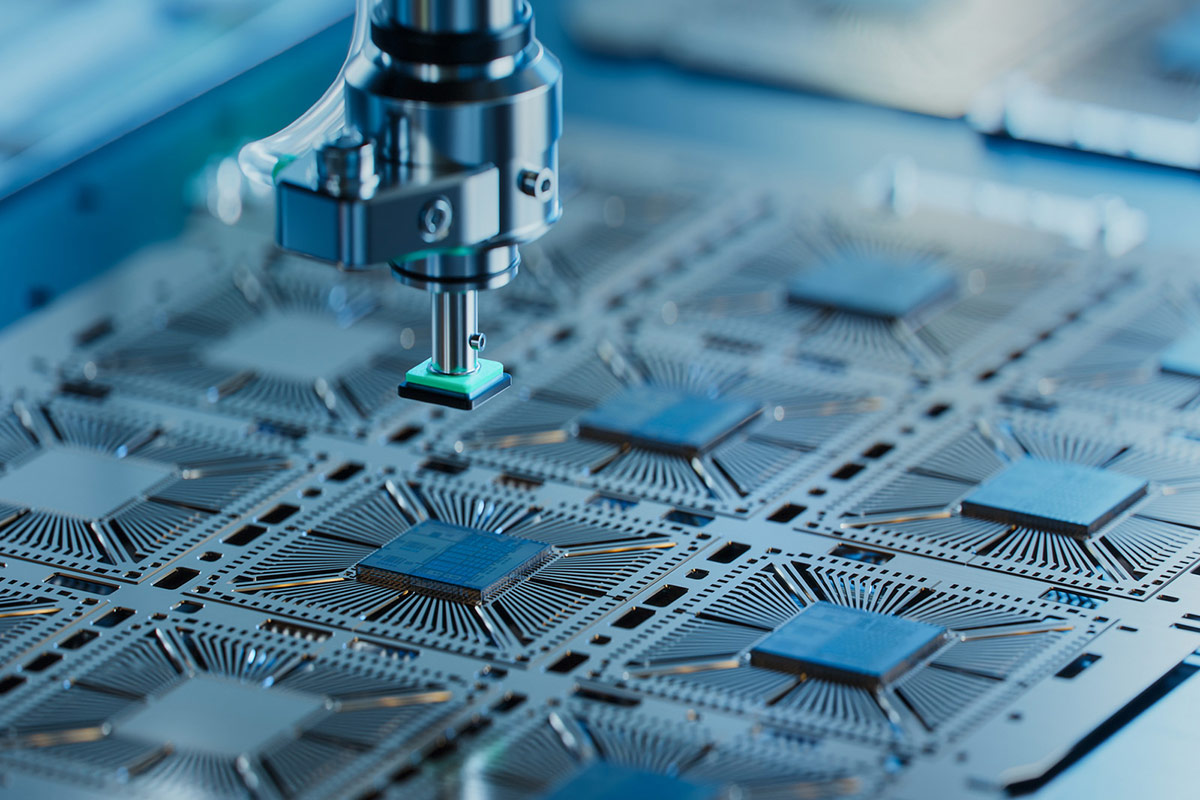

Applications for elastomer sealing in plasma processes can involve: door seals, centering rings for flanges, exhaust valves, window seals, valve seals, chamber lid seals, cushioning for wafer transport.

Delivering proven performance for leading semiconductor manufacturers

All seals, particularly those in critical locations, will degrade over a period of time. No single seal material is optimized for all chemistries or applicable to every tool location and product type. Appropriate choice of PPE recommended products will lead to:-

- Cost optimized recommendation dependent on application

- Low erosion rates

- Low trace metal levels where critical

- Low particle release rates where critical

- Minimized impact on device yield and electrical yield

- Reduced cost of consumables (CoC)

Recommended materials for plasma applications

The table below indicates recommended and compatible elastomer material grades. Primary grades are geared towards critical system/tool locations.

For further guidance on appropriate sealing choices in plasma environments, get in touch with our experts for application-specific advice.

| Process/application | Temperature range | Process media | Primary materials | Compatible materials |

|---|---|---|---|---|

| PECVD / HPDCVD | 25 – 300°C (77 – 572°F) | SiH4, N2, NH3, N2O, NO, Organosilanes/siloxanes, O2, CF4, C2F6, C3F8, SF6, SiF4, NF3 | G7HA, G65HP | G70H, G76W |

| Resist Strip / Ash | 25 – 200°C (77 – 392°F) | O2, CF4, SF6, CHF3, NH3, H2, H2O, NO, N2O, Forming Gas | G65HP, G70H | G75H, G76W |

| Dielectric Etch | 25 – 200°C (77 – 392°F) | H2, O2, CO, CO2, NO, NO2, N2O, CS2, COS, CF4, CH4, CHF3, C2F4, C2F6, C3F8, C4F8, C4F6, C4F10, C5F8, C6F6, SF6 | G65HP, G7HA | G70H, G75H, G76W |

| Conductor Etch | 25 – 200°C (77 – 392°F) | CF4, CHF3, C2F6, C3F8, SF6, HBr, BCl3, SiCl4, CCl4, Cl2, CCl2F2, O2, CO, NO, N2O, NF3 | G70H, G65HP | G75H, G76W, V75SC |