Semiconductor

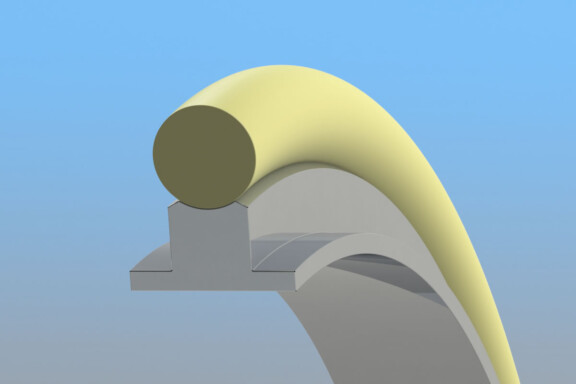

Elastomer seals for semiconductor production face incredibly challenging environments – including aggressive plasma chemistries, and extreme temperatures.

PPE material grades have been engineered to offer enhanced performance with reduced particle generation, to minimize yield loss.

We manufacture bespoke components for:

Semiconductor integrated circuits

Flat panel displays (FPD)

Solar cells (crystalline, multi-crystalline, concentrator)

MEMS

LED / OLED

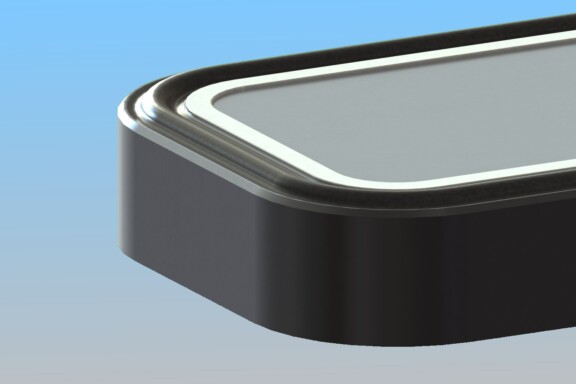

Semiconductor sealing solutions

PPE provides clean room manufactured seals with low particle and low trace metal contamination for minimized yield loss and low chemical erosion rates that offer the following benefits:

Extended system up-time

Increased mean time between failure (MTBF)

Decreased wet or mechanical clean frequency

Minimized cost of ownership (CoO)

Extended system up-time expand_more

Increased mean time between failure (MTBF) expand_more

Decreased wet or mechanical clean frequency expand_more

Minimized cost of ownership (CoO) expand_more

Semiconductor manufacturing processes

Find out more about thermal, plasma and wet chemical processes, and how PPE’s range of elastomer seals for semiconductor applications like these can represent a significant operational advantage.

Plasma Processes

Thermal Processes

Wet Chemical Processes

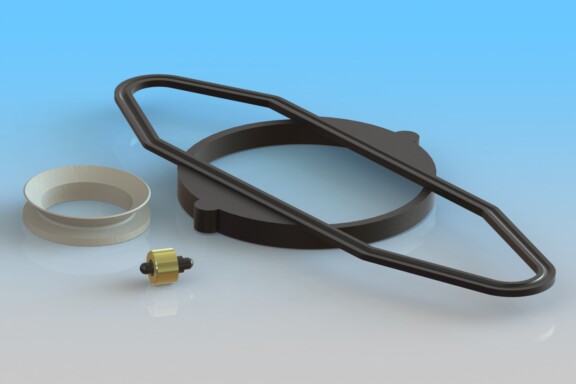

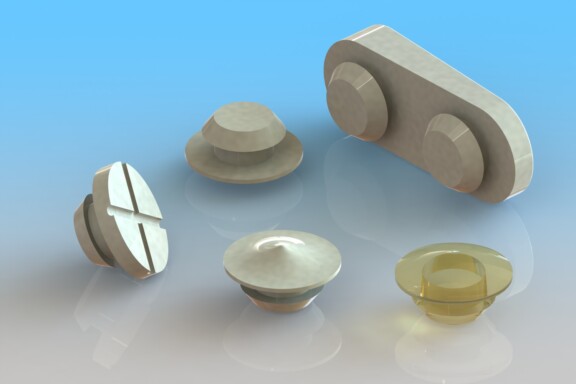

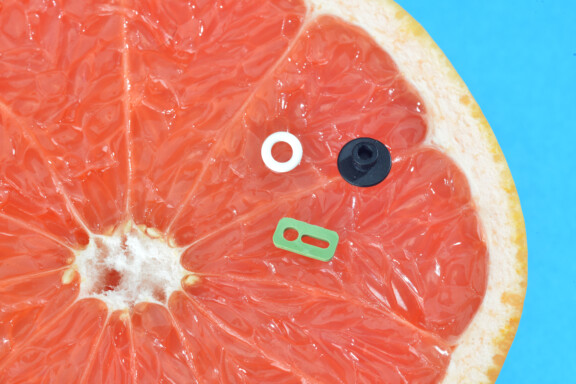

Products for semiconductor applications

Take a look at some of the key sealing products we supply to the semiconductor industry.

Semiconductor O-rings

Custom Seals

Wafer Handling Components

KF-ISO-NW Flange Fittings

Micro Seals

Slit Valve Doors

Need more help? Speak to one of our experts today.

Looking for more technical detail? Check out our Resources & Tools.

Resources

Browse our key resources on elastomer sealing for semiconductor applications, including videos, animations, brochures and webinars.

For our full range of support material, visit our Resources page.