Perlast® FFKM O‑rings & seals

Perfluoroelastomer (FFKM) is the most chemically resistant elastomer available and is effectively a rubber form of PTFE.

FFKM O-rings and seals are used in critical sealing applications where purity, high temperatures, chemical resistance and retention of sealing force are paramount.

Perlast® is the registered tradename of our FFKM elastomers, developed and exclusively molded by PPE, for the most challenging sealing environments.

Perlast® perfluoroelastomer sealing materials are at the leading edge of polymer technology – for unrivalled resistance to chemicals and extreme temperatures.

Key features of Perlast® FFKM

FFKM O-rings and seals manufactured from Perlast® perfluoroelastomers offer the ultimate sealing performance and reliability.

Universal chemical resistance

Universal chemical resistance

High temperature capability

High temperature capability

Outstanding mechanical properties

Outstanding mechanical properties

High purity grades

High purity grades

Compliant with various industry standards

Compliant with various industry standards

Perlast® perfluoroelastomers demonstrate almost universal chemical resistance (similar to PTFE), outperforming competitor FFKMs in many applications including amines and steam.

Perlast® perfluoroelastomers provide class-leading high temperature capability, able to withstand operating temperatures up to 350°C (662°F).

At the lower end of the temperature scale, Perlast® ICE material grades have been developed for sealing in temperatures as low as -46°C (-51°F).

FFKM O-rings and seals manufactured from Perlast® perfluoroelastomers deliver reliable performance in challenging environments.

With outstanding mechanical properties such as class-leading compression set, Perlast® parts last longer and reduce cost of ownership (COO).

Specialist Perlast® material grades have been developed to resist Rapid Gas Decompression (RGD) experienced in high pressure environments in oil and gas applications.

Perlast® perfluoroelastomers have been used in the semiconductor industry for many years.

PPE first launched its high purity FFKM sealing materials back in 2000, since then PPE have continued to develop innovative high purity materials for reduced process contamination in semiconductor applications.

Perlast® FFKM O-rings and seals are fully compliant with key industry-specific regulations, including but not restricted to:

- FDA, USP Class VI and 3A 18-03 compliance for food and pharmaceutical applications

- Rapid Gas Decompression (RGD) resistant materials for high pressure environments for oil and gas applications

Universal chemical resistance expand_more

Universal chemical resistance expand_more

Perlast® perfluoroelastomers demonstrate almost universal chemical resistance (similar to PTFE), outperforming competitor FFKMs in many applications including amines and steam.

High temperature capability expand_more

High temperature capability expand_more

Perlast® perfluoroelastomers provide class-leading high temperature capability, able to withstand operating temperatures up to 350°C (662°F).

At the lower end of the temperature scale, Perlast® ICE material grades have been developed for sealing in temperatures as low as -46°C (-51°F).

Outstanding mechanical properties expand_more

Outstanding mechanical properties expand_more

FFKM O-rings and seals manufactured from Perlast® perfluoroelastomers deliver reliable performance in challenging environments.

With outstanding mechanical properties such as class-leading compression set, Perlast® parts last longer and reduce cost of ownership (COO).

Specialist Perlast® material grades have been developed to resist Rapid Gas Decompression (RGD) experienced in high pressure environments in oil and gas applications.

High purity grades expand_more

High purity grades expand_more

Perlast® perfluoroelastomers have been used in the semiconductor industry for many years.

PPE first launched its high purity FFKM sealing materials back in 2000, since then PPE have continued to develop innovative high purity materials for reduced process contamination in semiconductor applications.

Compliant with various industry standards expand_more

Compliant with various industry standards expand_more

Perlast® FFKM O-rings and seals are fully compliant with key industry-specific regulations, including but not restricted to:

- FDA, USP Class VI and 3A 18-03 compliance for food and pharmaceutical applications

- Rapid Gas Decompression (RGD) resistant materials for high pressure environments for oil and gas applications

Typical Perlast® applications

The Perlast® range of perfluoroelastomer materials are at the leading edge of polymer technology. They have been developed by PPE to offer superior sealing solutions with enhanced performance and improved functionality, which has been proven in the field for over 20 years.

Perlast® parts are manufactured exclusively by PPE, for some of the most challenging sealing applications in the world.

Perlast® for life science applications expand_more

Perlast® perfluoroelastomers are the ultimate sealing material to overcome specific sealing challenges found in the food, dairy, pharmaceutical, biomedical and lifescience industries.

Perlast® G74S offers universal chemical resistance combined with high temperature capability up to +260°C (500°F). This material is also compliant with various industry standards including FDA, 3A, USP Class VI & EC requirements.

Perlast® for aerospace applications expand_more

Specialist material grade Perlast® G77X is a perfluorocarbon (FFKM) that has been developed specifically for critical aerospace applications.

Nadcap and AS9100 audited and certified, this material offers significant advantages over other elastomer materials in terms of long-term sealing performance.

Perlast® for oil & gas applications expand_more

Specialist grades of Perlast® perfluoroelastomers (FFKM) have been developed to withstand aggressive media, high pressure environments and extreme temperatures.

Perlast® FFKM materials are typically used to overcome specific sealing challenges found in the upstream, midstream and downstream sectors of the global oil and gas industry.

Perlast® for semiconductor applications expand_more

PPE developed the first high purity, translucent grades of Perlast® perfluoroelastomer back in the 1990’s. Since then, PPE has led the field by continuously innovating new FFKM materials to stay ahead of Moore’s law.

Our range of Perlast® perfluoroelastomer materials for semiconductor applications are at the leading edge of polymer technology. They have been developed to offer superior sealing solutions with enhanced performance and improved functionality, that provide proven benefits.

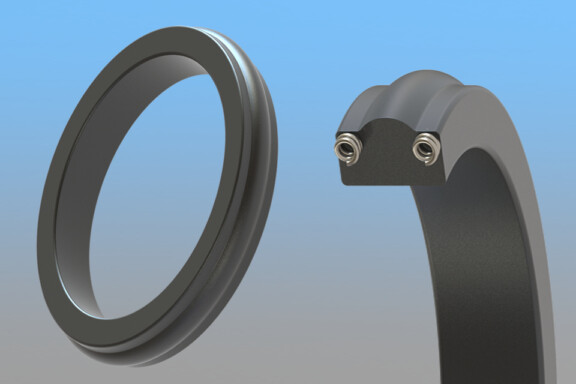

Perlast® for mechanical seals expand_more

Mechanical seals are widely used in rotating equipment, such as pumps and compressors.

Perlast FFKM O-rings are advantageous in keeping mechanical seals performing reliably. Some of the more critical O-rings in mechanical seals provide a static seal between the rotary rings and shafts, and also between the stationary rings and the equipment casing.

These O-rings are often exposed to aggressive process media, and the chemical resistant qualities of Perlast seals make it an excellent choice for underpinning class-leading performance.

Perlast® products

Perlast® parts are manufactured exclusively by PPE, for some of the most challenging sealing applications in the world.

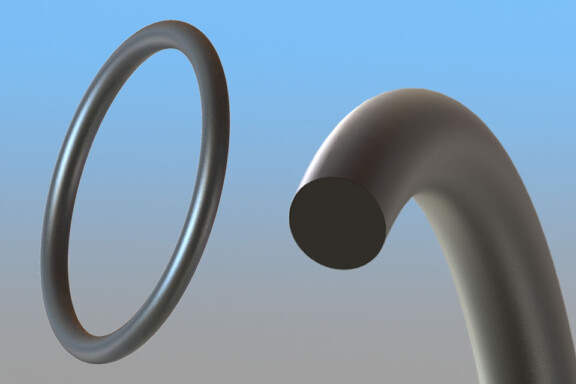

Elastomer O-Rings

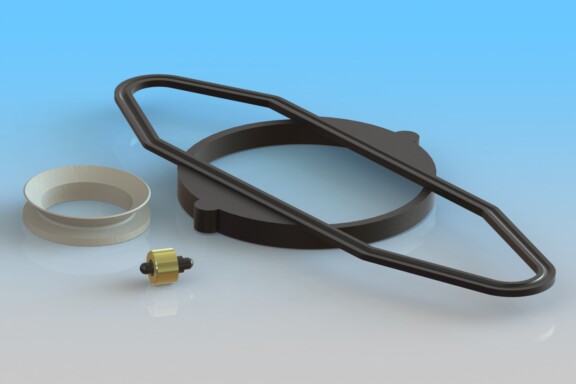

Custom Seals

HyClamp™ Sanitary Gaskets

Spring Seals

Resources

Below are some of our most popular downloads relating to Perlast®.

If you require further information on any sealing topic, check out our Resources section.

- Expert-led videos: Perlast® FFKMs

- An introduction to Perlast

- Perlast and high temperature sealing

- Perlast and chemical resistance

- Perlast and availability

- Perlast and regulatory compliance

- Perlast and expert technical support

- Video: ‘How O-rings are made’

- Case Study: Perlast seal extends life of vacuum discharge ball segment valves

- Benchmarking data: How does Perlast® compare to other FFKM materials?

Looking for more technical detail? Check out our Resources & Tools.

Need more help? Speak to one of our experts today.

FFKM FAQs

What is a perfluoroelastomer? expand_more

Perfluoroelastomer (FFKM) is a synthetic rubber combining fluorine with carbon, resulting in a material with improved chemical and heat resistance properties. Effectively a rubber form of PTFE, FFKM seals are a good choice for critical applications in all kinds of process industries – from energy and semiconductor manufacturing through to food and pharmaceutical production.

Is perfluoroelastomer the same as FKM? expand_more

The physical difference between FKM and FFKM, or perfluoroelastomer, is in the chemical makeup. Fluorinated elastomers can have either a fully or a partially fluorinated backbone. FFKMs are fully fluorinated. This higher amount of fluorine in a FFKM gives the material its improved capacity for chemical and thermal resistance.

What are the properties of perfluoroelastomer materials? expand_more

Perfluoroelastomer (FFKM) is used as a high performance sealing material in critical applications. This is due to its excellent resistance to chemicals – including hydrocarbons, acids, amines, solvents and steam – and its stability in high and low temperature extremes, responding well to temperature cycling. In addition to good mechanical properties, FFKM is an expensive elastomer, specified in applications where seal failure and associated operational downtime would be particularly costly.

What is the difference between FFKM and PTFE? expand_more

Both FFKM and PTFE are fluorocarbon polymers with similar properties in terms of heat resistance and chemical resistance. The fundamental difference is that FFKM contains hydrogen and oxygen as well as carbon and fluorine, additional monomers which make FFKM an elastomer without the ‘stiffness’ of PTFE.

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.