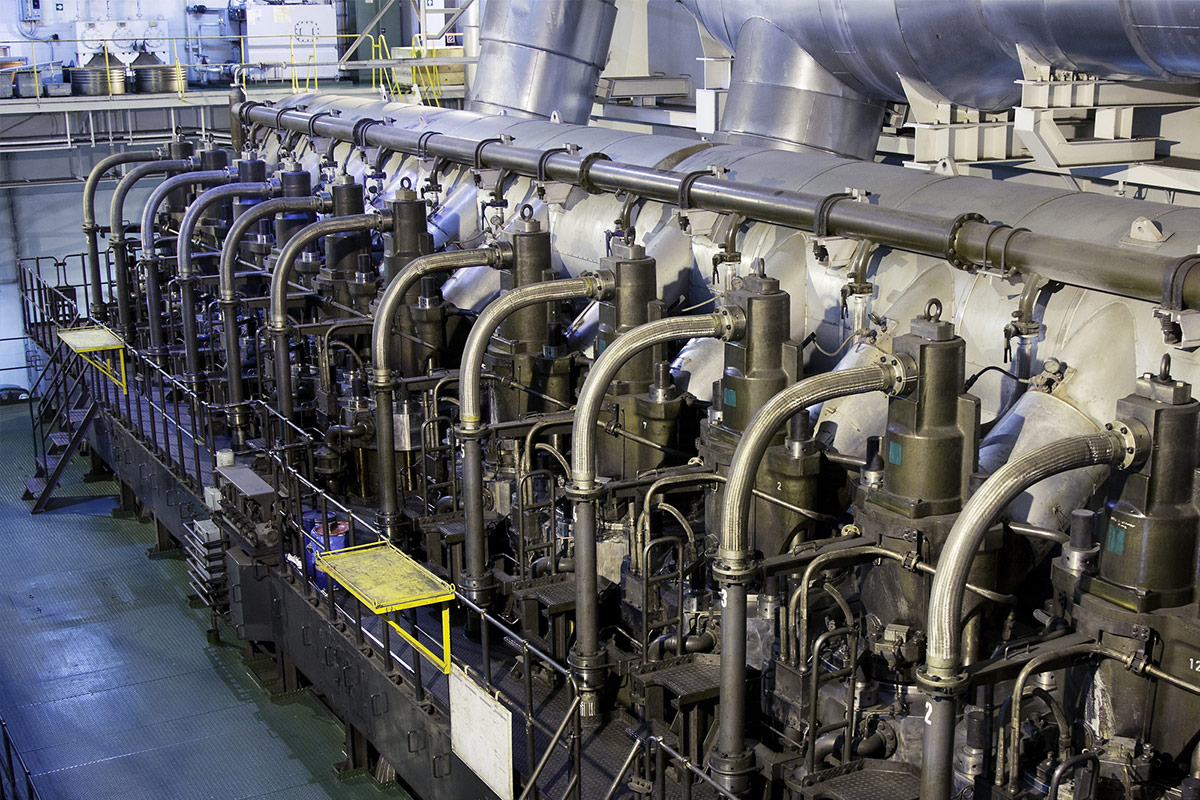

Power & Propulsion

Our engineers are at the forefront of engine sealing technology, developing high temperature seals for large bore diesel and gas engines, for marine propulsion and power generation.

We manufacture engine sealing components for:

Liner rings (up to 2000mm diameter)

Fuel: MDO, HFO, biofuels and gas

HP injectors

High temperature exhaust valve seats

Sump, access covers, and rocker covers

Cylinder joints

Turbochargers

Lubrication oil

PPE seals are specified on 2 and 4 stroke engines, both small and large capacity.

Engine sealing benefits

PPE’s specialist sealing engineers understand the pressures manufacturers and operators are under in the marine, diesel and power-gen sectors, to generate better performance and achieve the best possible equipment reliability. Our innovative elastomer sealing materials and products are developed with these demands in mind.

Reliability

Efficiency and economy

Extended maintenance intervals

Reduced emissions

Reliability expand_more

Efficiency and economy expand_more

Extended maintenance intervals expand_more

Reduced emissions expand_more

PPE Material Brands

Elastomers typically offered for these applications include Perlast® perfluoroelastomers (FFKM), FKM, EPDM, NBR, HNBR, and silicone (VMQ).

Perlast®

expand_moreThe ultimate perfluoroelastomers for sealing applications where chemical resistance and high temperature performance are critical.

Products for engine sealing

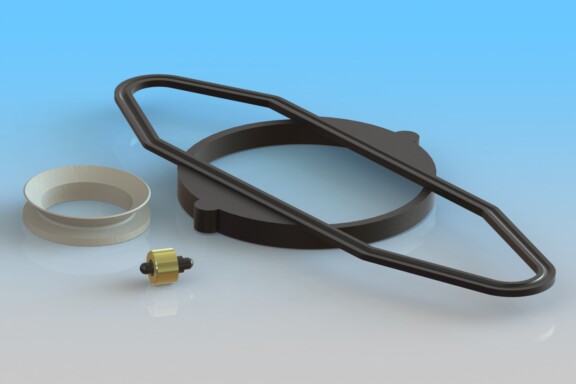

PPE offers a complete range of engineered solutions for engine sealing requirements, including:

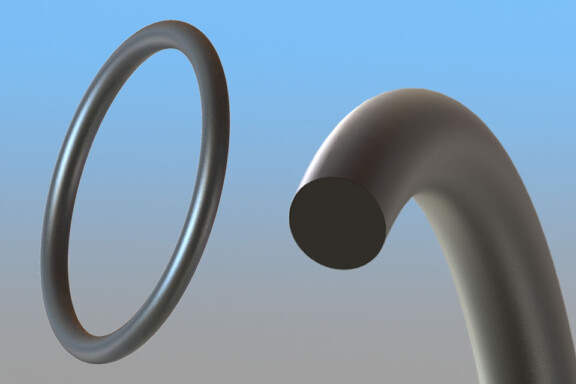

Elastomer O-Rings

Large Diameter O-Rings & Seals

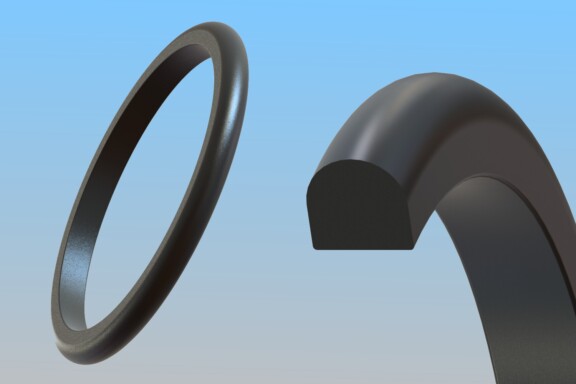

D-Rings

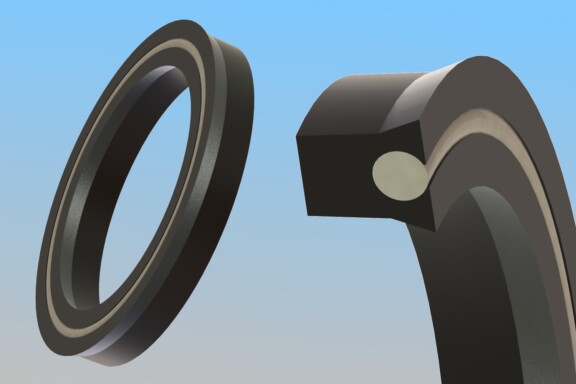

Lip Seals

Custom Seals

Looking for more technical detail? Check out our Resources & Tools.

Need more help? Speak to one of our experts today.

Resources

Here are some relevant key resources which provide practical insights into the world of elastomer sealing for power and propulsion.

You can also browse our full range of resources for expert support on all aspects of high performance sealing.