Elastomer Materials Lab

In the PPE Elastomer Materials Lab, our team offers an extensive range of independent testing and consultancy services for companies and organizations which are looking for assistance in investigating polymeric materials.

Key testing capabilities include:

- Physical property determination at different temperatures

- Thermal analysis

- Spectroscopy

- Microscopy

- Post-application analysis

- Chemical Compatibility

About PPE and materials technology

Materials technology is at the core of the business within PPE Ltd. Our purpose-built facilities (located in the UK, Houston TX, and Dammam, KSA) include a state-of-the-art laboratory and development cell and all offer a comprehensive range of services for the development, characterization, testing, and analysis of polymeric materials.

The development cell possesses a wide range of equipment dedicated to the optimisation of manufacturing processes for new and novel materials. As new materials and designs are developed, processing characteristics are fully understood before full manufacturing commences.

With the Elastomer Materials Lab at your disposal, we offer a complete consultancy service, including expert polymer chemists, seal design engineering, advice and assistance in material selection, material testing, sample analysis and problem-solving on any sealing matter.

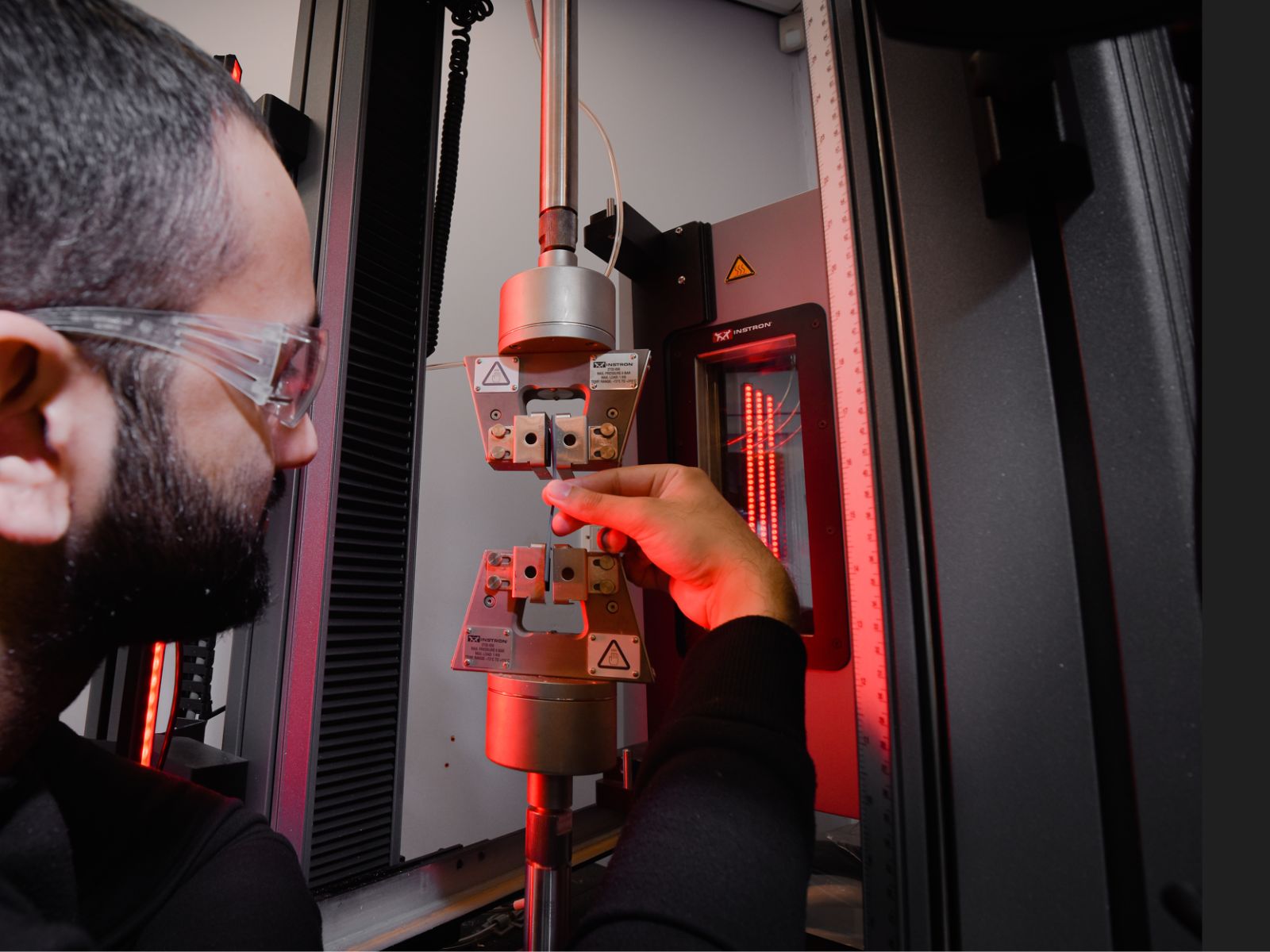

A cutting-edge environment for elastomer testing, analysis and problem solving, including seal failure analysis.

Key capabilities

Physical property determination at different temperatures expand_more

Using environmental chambers to test the physical properties of materials at actual or elevated operating temperature provides accurate results which are much more representative of actual applications. The data is then used in Finite Element Analysis (FEA) computer modeling to create accurate simulations of seal designs.

Thermal Analysis: Differential Scanning Calorimetry (DSC) expand_more

DSC analysis depends upon comparing the exothermic and endothermic reactions of samples and a reference, as the sample and reference are heated through a defined heating regime. The technique enables the accurate determination of glass transition temperatures, crystallization and melting points and in the case of elastomers, cure characteristics.

This technique is valuable for failure analysis, compound development and determining the low temperature performance of a sealing material.

Thermal Analysis: Thermogravimetric Analysis (TGA) expand_more

TGA analysis depends upon the accurate weighing of a sample as it is heated, from – typically -25°C to 800°C. As the heating progresses, different components of the elastomer formulation ‘bu off’ thereby reducing the weight. A step-like patte emerges which correlates quantitatively with the components of the formulation.

This technique is valuable for compound development, reverse-engineering, process control and failure analysis.

Infra-red Spectroscopy (FTIR) expand_more

FTIR involves passing an infra-red light through, or impinging on, a sample of material. The light gives up some of its energy, causing various molecular structures in the sample to vibrate, twist or stretch. The resultant light is then compared with a reference light stream and the result is represented as a characteristic plot of peaks.

This technique is helpful in ‘fingerprinting’ materials, failure analysis and compound development.

Microscopy expand_more

Utilising stereo microscopes, featuring industry leading optics, large zoom ranges, wide fields of view and high definitions camera systems coupled with powerful imaging software, enables macro-to micro-imaging analysis. From routine surface morphology observations, particle analysis, cross sectional investigations to detailed post application analysis of elastomeric parts and investigation of failure mechanisms, microscopy can be a powerful tool to determine and optimise seal performance, support quality control and continuous improvement activities.

Chemical compatibility expand_more

Seal materials are often used in unique combinations of fluids over a wide variety of temperatures. Test facilities at PPE allow chemical compatibility trials to be performed to address specific customer needs. Changes in physical properties for various materials can be examined, so that the best polymer material for the chemical environments can be determined.

Post-application analysis expand_more

A seal that has been utilized in a specific application is analyzed using the various techniques mentioned above, to investigate its conditions after use. If the seals show signs of damage, further investigation is carried out, to differentiate between thermal and chemical degradation and other possible causes, such as mechanical failure, environmental stress, premature ageing, contaminants/inclusions and poor design. PPE provides assistance in recommending alte ative designs or materials.