Our Capabilities

PPE’s sealing specialists will work with you to identify what matters most to you from your seals.

That’s how we can make the biggest positive impact to your operations, and customize a sealing solution to deliver the clearest improvements where you want to see them – whether that’s performance, reliability, environmental impact, or consumer safety.

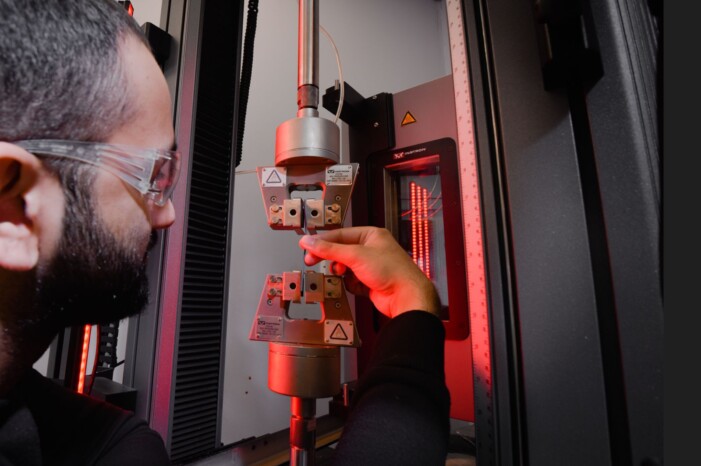

Elastomer Materials Lab

Chemical compatibility, thermo-mechanical evaluation, failure analysis and explosive decompression testing are services available from PPE's laboratories.

Availability of standard products

PPE offers some of the shortest manufacturing lead times in the sealing industry, for the molding of O-rings in any elastomer material.

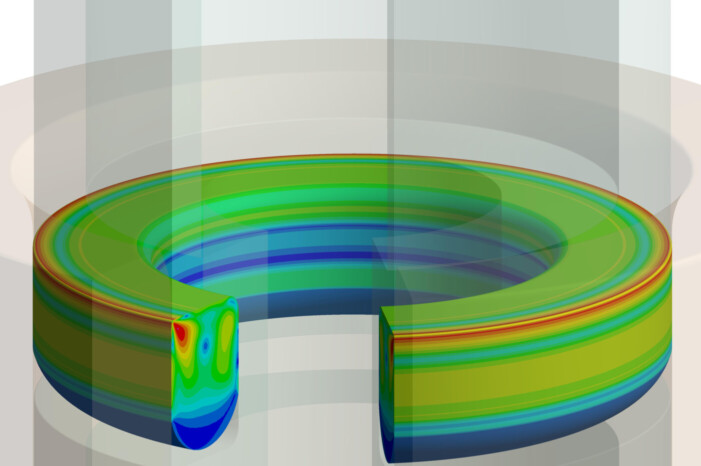

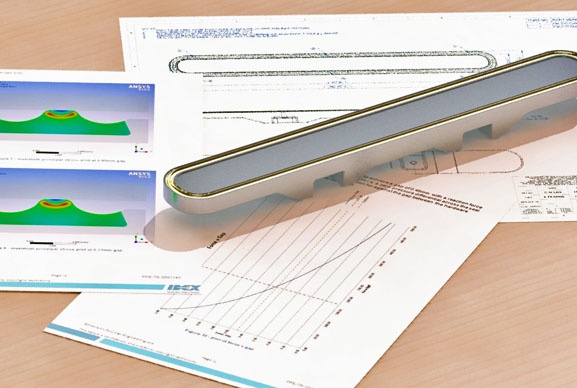

Finite element analysis

Finite Element Analysis (FEA) is used to predict contact forces, deformation and stress levels within elastomer components to simulate how they will perform in real-life applications.

Consultancy

Precision Polymer Engineering is a trusted provider of sealing consultancy for companies across the world.

Component design

Discover more about our comprehensive component design and modelling service for seals, custom-molded elastomers, and bonded components,

Clean rooms

PPE operates five clean rooms dedicated to the controlled manufacture of high performance seals for applications where purity matters most.

Services

Precision Polymer Engineering offers a comprehensive range of sealing services alongside its high performance sealing products.

Quality

With a firm belief in the importance of continuous improvement, PPE is always driven to uphold the highest of industry standards across Quality, Health & Safety, Value, Service, Delivery, Technology and Environment.

Why choose Precision Polymer Engineering?

Ready to see how Precision Polymer Engineering can solve your toughest sealing challenges?