Chemical Processing

Precision Polymer Engineering’s range of high performance CPI seals – including Perlast® FFKM O-rings and custom seals – have been developed specifically for critical chemical processing applications.

Chemical Resistance and Sealing

Chemical processing applications – such as sealing pumps, valves, tanks and fluid metering devices – require high performance CPI seals with three key characteristics:

- Outstanding chemical resistance to various aggressive media

- Resistance to high and low temperature extremes

- Robust mechanical strength

Our sealing specialists can advise on optimal sealing materials for the demands of any chemical process application, delivering operational improvements including:

Better reliability

Extended planned maintenance cycles

Improved operating margins

Lower cost of ownership

Better reliability expand_more

Extended planned maintenance cycles expand_more

Improved operating margins expand_more

Lower cost of ownership expand_more

Perlast® perfluoroelastomers (FFKM) provide the highest level of thermal and chemical resistance available, making them ideal for use in the most demanding chemical sealing applications.

Alongside Perlast® FFKMs, PPE offers sealing solutions in

- FKM

- FEPM

- HNBR

For valves operating in cold temperatures, Perlast® ICE material grades have been engineered to reduce the risk of seal failure significantly.

CPI Seals and Gaskets

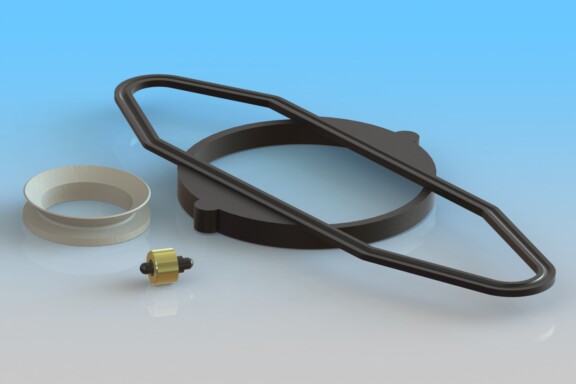

Combining material science innovation with engineering expertise to develop optimal seal designs, PPE can deliver exceptional sealing solutions for pumps, valves, mechanical seals, pipe couplings and reactors in any chemical processing market.

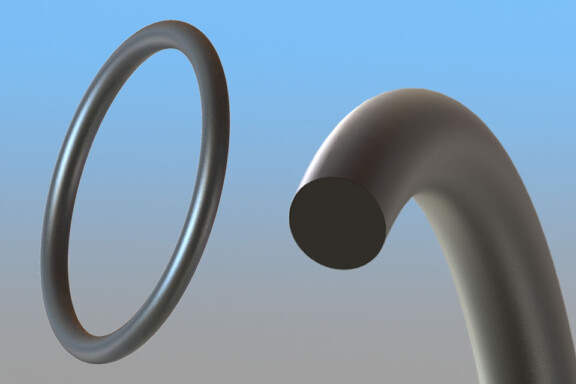

Elastomer O-Rings

Custom Seals

Downstream Oil & Gas

PPE Material Brands

PPE sealing solutions for chemical processing applications are manufactured in the following material brands:

Perlast®

expand_moreThe ultimate perfluoroelastomers for sealing applications where chemical resistance and high temperature performance are critical.

Perlast® ICE

expand_moreExcellent resistance to a broad range of chemicals, with exceptional low temperature performance down to -46°C (-51°F)

FAQs

How are seals damaged by chemicals? expand_more

Elastomer seals used in a chemical process application, or subject to chemical cleaning regimes, can be subject to chemical attack. Different elastomer seals will react differently with different chemicals, a process which can be accelerated in higher temperatures and for seals under mechanical stress.

The most frequent result of chemical attack on elastomers is an increase in cross-link density, which results in a hard and brittle sealing material, and reduced reaction force. Chain scission is also possible, leading to reduced strength. Occasionally, cross-link densities can reduce, resulting in a softer tacky seal, and loss of original shape and integrity.

Correct elastomer material selection is key for compatibility with the application media. PPE sealing specialists can advise on the most appropriate sealing material for your application.

What is the best seal for chemicals? expand_more

Perfluoroelastomer, or FFKM, is the most chemically resistant elastomer material. Effectively a rubber form of PTFE, FFKM is chemically inert in most applications, and also retains sealing force in extreme high and low temperatures.

Perlast® is PPE’s own highly specialised family of FFKM material grades. Perlast® materials are at the leading edge of polymer technology, and deliver performance, reliability, and purity in a wide range of critical semiconductor, food, pharmaceutical and energy applications.

What O-rings are chemical resistant? expand_more

The chemical resistance of an elastomer seal is dependent on the material it is made from, and the chemical it is exposed to. FKM is excellent in hydrocarbons but poor in amines. HNBR is excellent in steam but poor in aldehydes. It depends entirely on your application.

Perfluoroelastomer, or FFKM, is a material which performs exceptionally in any environment. It provides thermal stability and almost universal chemical resistance. Ask your PPE sealing specialist about Perlast® FFKM, PPE’s family of FFKM materials, or whether another material would work well in your specific application.

Need more help? Speak to one of our experts today.

Looking for more technical detail? Check out our Resources & Tools.

Resources for CPI Seals

Browse our library of videos and downloadable content for practical insights into effective elastomer sealing for chemical processing applications.