Rapid Gas Decompression resistant elastomers

Rapid Gas Decompression (RGD) resistant elastomer seals are typically used in high pressure applications encountered in the energy industry.

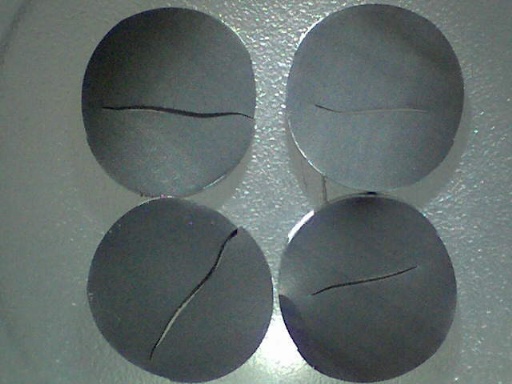

Rapid Gas Decompression (also referred to as Explosive Decompression) is a failure mechanism of elastomer seals that is caused by a rapid reduction in pressure of a gaseous media. Gas that has permeated into the elastomer seal expands abruptly upon rapid pressure release causing fissuring, cracking and ultimately seal failure.

Cross section of a RGD damaged O-ring

RGD O-rings & seals

RGD resistant seals and RGD O-rings are available from PPE in a range of elastomer material types including HNBR, FEPM (Aflas®), FKM and FFKM under the brand names EnDura®, Perlast® and Perlast® ICE.

PPE’s RGD resistant elastomer materials have been tested to the standards listed above and RGD test certificates are available to download.

PPE elastomers tested to RGD standards

The following PPE material grades have been developed for RGD resistance and are available in a range of fully molded components – see Products section.

| Material grade | Material type | Description | NACE TM0192 | NACE TM0297 | ISO 23936-2 | TOTAL GS PVV 142 |

| EnDura® A90H | FEPM | Aflas® based copolymer | Not tested | Pass* | Pass | Pass |

| EnDura® V91JF | FKM | General purpose grade | Not tested | Not tested | Pass | Not tested |

| EnDura® V91KF | FKM | Low temp grade | Not tested | Not tested | Pass | Not tested |

| EnDura® V91A | FKM | Ultra-low temp grade | Not tested | Pass | Pass | Pass |

| EnDura® Z95X | HNBR | General purpose grade | Pass | Pass* | Pass | Pass |

| Perlast® G92E | FFKM | Chemical res. grade | Not tested | Pass* | Pass | Pass |

| Perlast® G90LT | FFKM | Low temp grade | Not tested | Pass* | Pass | Pass |

Visit the Resources section to view/download material datasheets and test certification.

EnDura® and Perlast® are registered trademarks of Precision Polymer Engineering.

Aflas® is a registered trademark of the Asahi Glass Co. Ltd

RGD testing of elastomers

International standards for testing elastomers in RGD conditions include the following:-

- NORSOK M710 Rev.2 Section 7.3 Annex B

- ISO 23936-2 Section 7 and Annex B

- NACE TM0192

- NACE TM0297

- TOTAL GS PVV 142, Appendix 8

| NORSOK M710 Rev.2 | ISO 23936-2* | NACE TM0192 | NACE TM0297 | TOTAL GS PVV 142 | |

|---|---|---|---|---|---|

| Specimen | ISO3601 -325 O-ring | ISO3601 -312 O-ring or larger | ISO3601 -325 O-ring | ISO3601 -325 O-ring | ISO3601 -349 or -425 O-ring |

| Constraint | 20% compression | 14.5% compression | Optimal | Optimal | 13.5% compression |

| Replication | Three | Four | Three | Nine | Three |

| Gas (%) | 90/10% CH4/CO2 | 90/10% CH4/CO2 | 100% CO2 | 100% CO2 | 80/20% CH4/CO2 |

| Temperature | 100°C / 212°F | 100°C / 212°F | 25°C / 77°F | 120°C / 248°F | 75°C / 167°F |

| Pressure | 15 MPa / 2176 Psi | 15 MPa / 2176 Psi | 5.2 MPa / 754 Psi | 7 MPa / 1015 Psi | 19 MPa / 2756 Psi |

| Initial soak period | 72 hours | 68 hours | 0 | 0 | 78 hours |

| Soak period | 24 hours | 6 and 12 hours alternating | 24 hours | 24 hours | 48 hours |

| Decompression rate | 3 MPa/min | 2 MPa/min | 5.2MPa/min | 7 MPa/min | 19 to 0 MPa in 90 secs |

| Dwell at ambient pressure | 1 hour | 1 hour | 0 | 0 | 1 hour |

| Cycles | 10 | 8 | 1 | 1 | 5 |

Resources

Browse our library of resources that provide practical insights into the world of elastomer sealing.

What is Rapid Gas Decompression (RGD)?

Material info sheets: