Component design

PPE offers a comprehensive component design and modelling service for seals, custom-molded elastomers, and bonded components.

Typical PPE component design services include:

Material recommendations

O-ring size optimization

Groove size recommendations

Custom seal design

Expert support

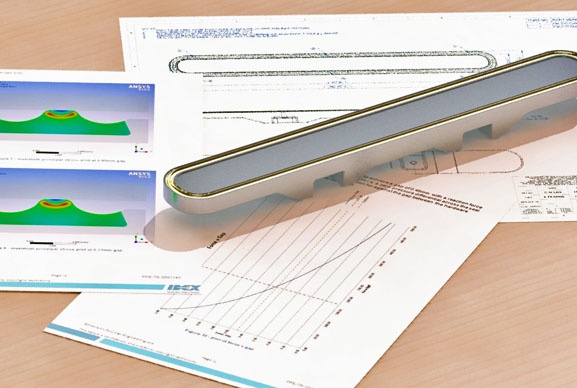

PPE application engineers design components using SolidWorks®, which offers three-dimensional parametric Computer Aided Design (CAD) capabilities. Design intent is captured once into CAD and then reused to drive all design and manufacturing processes – from 2D and 3D non-linear Finite Element Analysis (FEA) using ANSYS®, through tool manufacture, to 3D work instructions and 2D inspection drawings.

Our team of designers capture customer requirements and translate these into hardware recommendations and custom designs. Various formats of electronic drawings are accepted including IGES, STEP, PARASOLID, PRO-E®, Inventor, DXF, DWG, and many more.

These can then be imported into SolidWorks® for our team of design engineers to work with. Components are designed in 3D CAD, and when required, are validated using FEA.