Services

Precision Polymer Engineering offers a comprehensive range of sealing services alongside its high performance sealing products. This ensures that whatever your application or industry, you get the most effective long-term solution to any sealing problem.

Our specialist sealing engineers are on hand with support options ranging from initial component design support to failure analysis testing. Whether you’re looking to improve efficiency, or reduce costs in your operations, our expertise is invaluable.

Key sealing services

Consultancy

The polymer experts in our materials department offer professional advice and consultancy on any sealing challenge.

We can help identify the best performing seal type, profile and material for the demands of any application. Testing capabilities include chemical compatibility, thermo-mechanical evaluation and explosive decompression testing.

Component design

Ensure that your sealing system is optimized for your application with our custom component design service. From original specification and design through to precision molding in recommended materials, PPE handles each step accurately and reliably for the highest quality parts every time.

Seal failure analysis

If you have experienced a seal failure but are unsure of the root cause, our sealing engineers can analyse the issues and identify a solution to prevent the problem happening again. We have cutting edge testing equipment to investigate the medium the seal came into contact with, the design of the seal, and the pressures and temperatures involved – and the effects these factors might have on seal performance.

PPE can assist with:

- Thermogravimetric Analysis (TGA)

- Differential Scanning Calorimetry (DSC)

- Fourier Transform Infrared Analysis (FTIR)

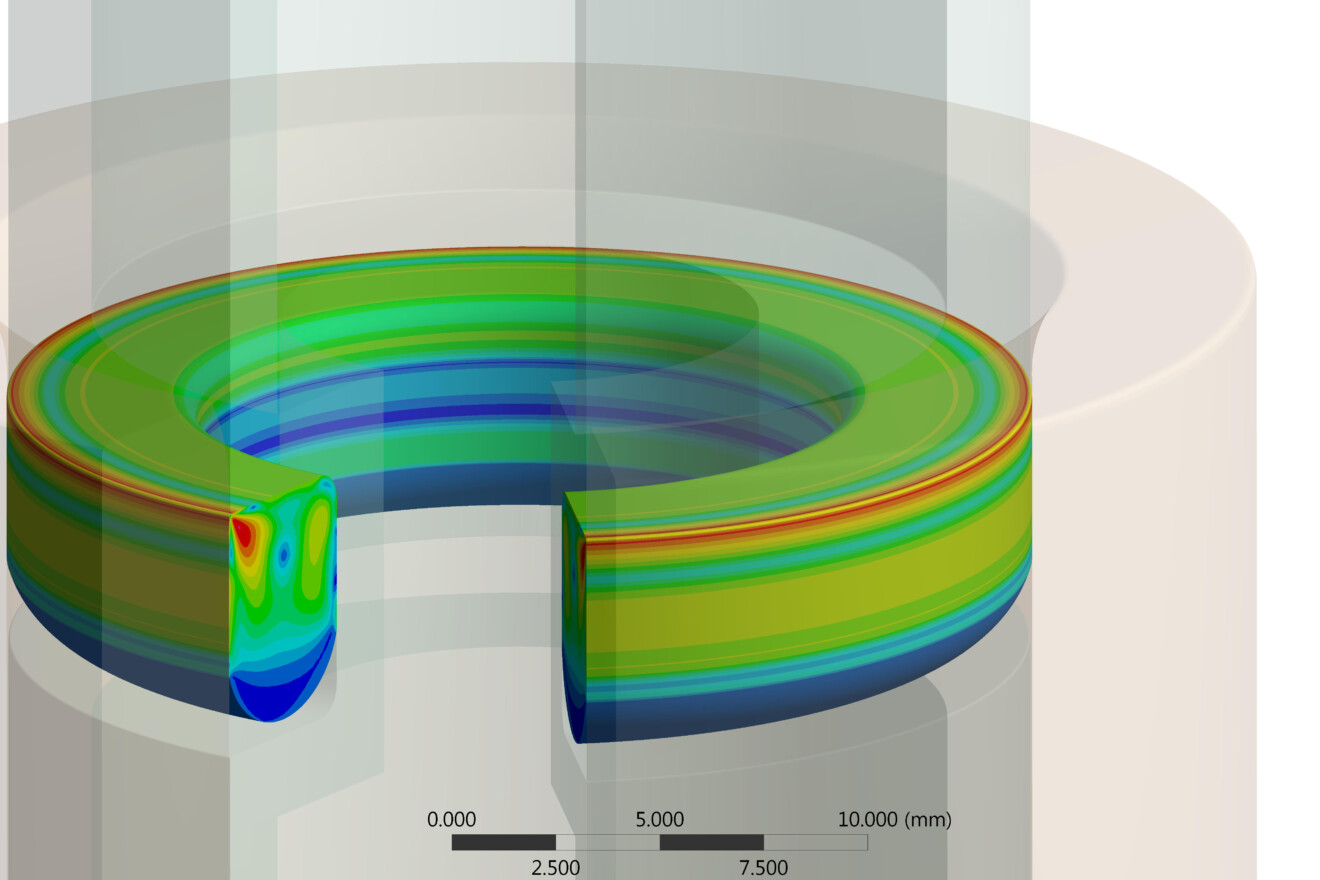

Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is a computer based technique used to analyse engineering applications and sealing components, to understand their behaviour under a variety of conditions. This analysis involves Finite Element Modelling (FEM), which is often used for new component design, or refinements to existing product designs.

In this virtual environment, our engineers can predict how sealing components will perform in real-life applications.

Clean room manufacturing

PPE offers elastomer molding and packaging in a carefully controlled manufacturing environment, ensuring the highest quality sealing products for semiconductor, food/dairy, and pharmaceutical and bio-medical industries and applications.

PPE operates Class 10,000 (ISO Class 7) and Class 1,000 (ISO Class 6) clean room environments across sites in the UK and USA.

Manufacturing lead times

Precision Polymer Engineering is renowned for offering some of the shortest lead times in the sealing industry.

For O-rings in any elastomer material, our specialists are trusted to deliver high quality parts to the strictest timeframes, to keep critical operations running with minimal interruption.