Perlast® for semiconductor

Perlast® Helios G7HA is a specially developed semiconductor sealing material which has been engineered to deliver superior plasma resistance in high temperature applications.

Key features include:

- Fully organic, high purity perfluoroelastomer (FFKM)

- Extremely low trace metal levels

- Excellent plasma resistance

- High temperature performance up to 310°C

- Outstanding long-term mechanical performance

Perlast® semiconductor FFKM grades have been proven to offer the lowest particle and trace metal contamination for minimized yield loss and low chemical erosion rates.

Key features

Perlast® perfluoroelastomers are recommended for thermal, plasma, and wet chemical semiconductor processes. This family of materials is proven to extend system up-time and extend planned maintenance intervals.

Low trace metal contamination expand_more

Particles and metallic ion contamination are a constant threat to the manufacture of semiconductor devices. The smaller the device, the greater the potential for harm and increased cost as the level of permissible contamination reduces.

When choosing elastomer seals for critical applications, device manufacturers must ensure that they select appropriate materials with ultra-low levels of trace metals, in order to avoid contamination and device degradation.

Perlast® materials consistently score well for cleanliness, across both low and ultra-low level metallic impurities (down to part per billion levels).

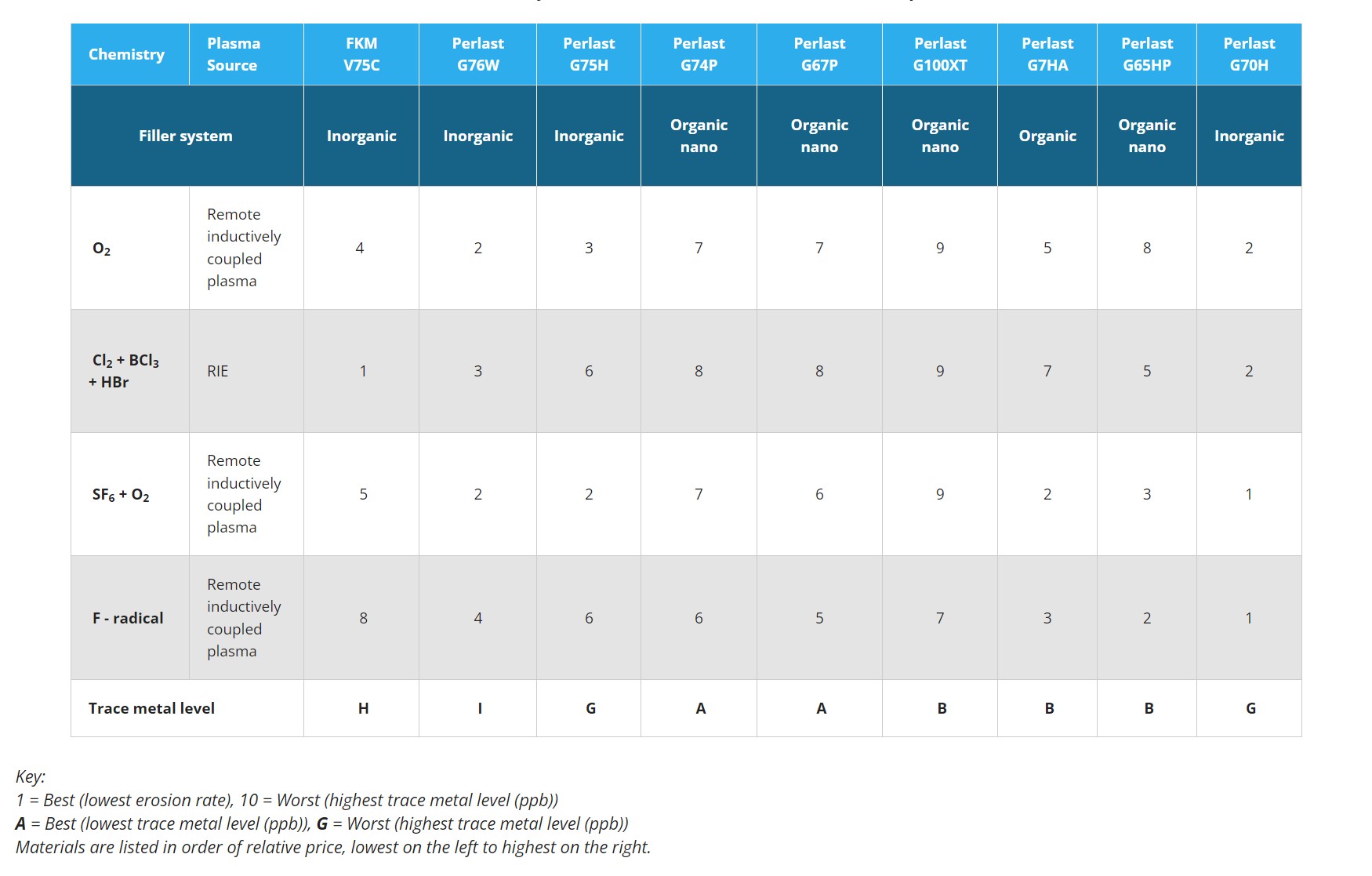

Plasma resistance expand_more

Perlast® materials have been extensively tested through exposure to a number of different plasma chemistries commonly used in etch processes and deposition chamber cleaning processes.

Perlast® seals for semicon applications

Perlast® materials are available as a wide range of fully molded components. All parts are manufactured exclusively in PPE’s clean rooms located in Blackburn, UK and Brenham, Texas.

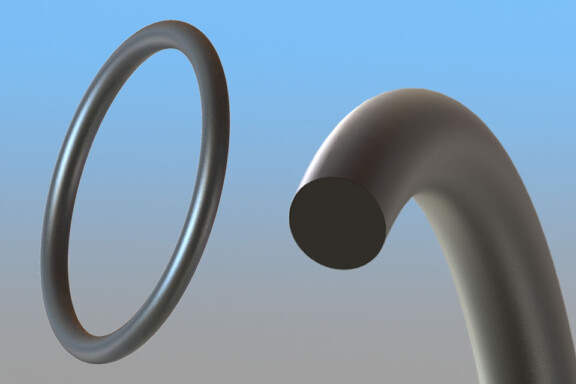

Elastomer O-Rings

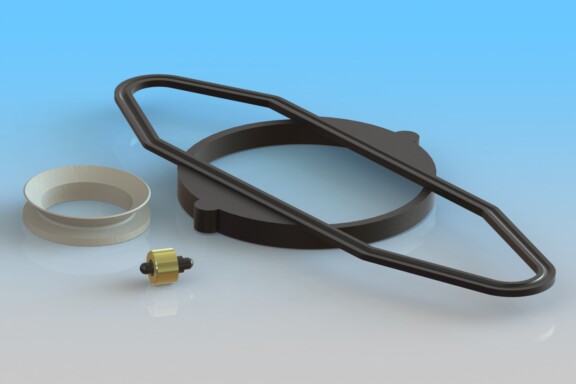

Large Diameter O-Rings & Seals

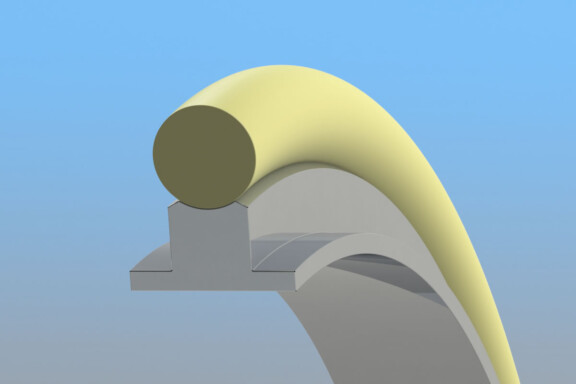

Custom Seals

KF-ISO-NW Flange Fittings

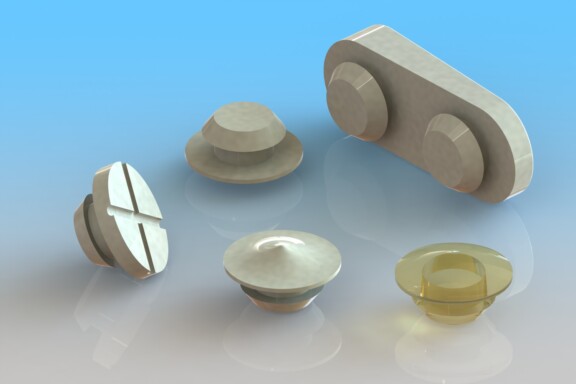

Wafer Handling Components

Slit Valve Doors

Resources

Below are some of our most popular downloads relating to Perlast® O-rings and seals for use in semiconductor applications.

If you require further information on any sealing topic, check out our Resources section.

- Webinar: Purity or plasma resistance – can you have both?

- Webinar: Critical sealing for high temperature semiconductor applications

- Video guide: What is ‘outgassing’, and how to prevent it?

- Benchmarking data: How does Perlast® compare to other FFKM materials?

Looking for more technical detail? Check out our Resources & Tools.

Need more help? Speak to one of our experts today.

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.