Perlast® for oil & gas

Perlast® FFKM seals for oil and gas applications are relied on to overcome the specific challenges found in the upstream, midstream and downstream sectors of the global oil and gas industry.

These specialist components are used in applications including down-hole tools, subsea equipment and infrastructure, pipeline connectors, valves, compressors, pumps and mechanical seals.

Perlast® G92E is a rapid gas decompression (RGD) resistant perfluoroelastomer that can be used in high temperature, high pressure environments, such as ultra-deep water HP/HT applications of 18,000 psi and 177°C (350°F) and above.

Perlast® combines high temperature and high pressure sealing performance with RGD resistance for downhole applications.

Key features of Perlast® FFKM

Perlast® perfluoroelastomers are used across upstream, midstream and downstream oil and gas applications, to ensure long term reliability and exceptional sealing performance.

Universal chemical resistance

Universal chemical resistance

High temperature capability

High temperature capability

Rapid Gas Decompression (RGD) resistance

Rapid Gas Decompression (RGD) resistance

Sour gas resistance

Sour gas resistance

Perlast® is engineered for high temperatures and pressures, but as a perfluoroelastomer material, operators can expect virtually universal chemical resistance.

In critical oilfield applications, this includes steam, amines, polar solvents, aromatic hydrocarbons, oil, fuels and thousands of other chemicals which may corrode less resilient materials.

Perlast® perfluoroelastomers are used for high temperature high pressure (HTHP) applications where seal failure is not an option.

PPE offers material grades which perform up to 260°C (500°F).

At the other end of the scale, Perlast® ICE grades have been engineered to seal reliably down to -146°C (-51°F).

FFKM O-rings and seals manufactured from Perlast® are resistant to the risk of explosive decompression (ED), otherwise known as rapid gas decompression (RGD).

RGD is a failure mechanism of elastomer seals caused by a rapid reduction in pressure of a gaseous media. Gas that has permeated into the elastomer seal expands violently when the pressure is released, rapidly causing fissuring and seal failure.

PPE’s range of Perlast® materials are tested to a series of international standards, including:

- NORSOK M-710

- NACE TM0297

- ISO 23936-2 Section 7 and Annex B

Sour gas can have detrimental effects on elastomer materials. Elastomers which are non-resistant can quickly become hard and brittle, losing their elastic properties and subsequently their ability to seal effectively.

Perlast® materials are certified as resistant to sour gas, to the following international sour gas test standards and conditions:

- NORSOK M-710 Annex A – Ageing of elastomeric materials (section 7.2)

- ISO 10423 (API 6A) – Petroleum and natural gas industries – Drilling and production equipment – Wellhead and Christmas tree equipment section F.1.13.5.2 (DD/EE and FF/HH)

- NACE TM0187 – Elastomeric materials in sour gas environments

- ISO 23936-2 Section 7 and Annex A “Petroleum, petrochemical and natural gas industries: Non-metallic materials in contact with media related to oil and gas production – Part 2: Elastomers

These are standard tests. PPE has however gone further, with high concentration testing at 25% H2S rather than the minimum requirement of 2%. These higher concentrations are more representative of real-world conditions, and give a better representation of the efficacy of Perlast® in situ.

Universal chemical resistance expand_more

Universal chemical resistance expand_more

Perlast® is engineered for high temperatures and pressures, but as a perfluoroelastomer material, operators can expect virtually universal chemical resistance.

In critical oilfield applications, this includes steam, amines, polar solvents, aromatic hydrocarbons, oil, fuels and thousands of other chemicals which may corrode less resilient materials.

High temperature capability expand_more

High temperature capability expand_more

Perlast® perfluoroelastomers are used for high temperature high pressure (HTHP) applications where seal failure is not an option.

PPE offers material grades which perform up to 260°C (500°F).

At the other end of the scale, Perlast® ICE grades have been engineered to seal reliably down to -146°C (-51°F).

Rapid Gas Decompression (RGD) resistance expand_more

Rapid Gas Decompression (RGD) resistance expand_more

FFKM O-rings and seals manufactured from Perlast® are resistant to the risk of explosive decompression (ED), otherwise known as rapid gas decompression (RGD).

RGD is a failure mechanism of elastomer seals caused by a rapid reduction in pressure of a gaseous media. Gas that has permeated into the elastomer seal expands violently when the pressure is released, rapidly causing fissuring and seal failure.

PPE’s range of Perlast® materials are tested to a series of inte ational standards, including:

- NORSOK M-710

- NACE TM0297

- ISO 23936-2 Section 7 and Annex B

Sour gas resistance expand_more

Sour gas resistance expand_more

Sour gas can have detrimental effects on elastomer materials. Elastomers which are non-resistant can quickly become hard and brittle, losing their elastic properties and subsequently their ability to seal effectively.

Perlast® materials are certified as resistant to sour gas, to the following inte ational sour gas test standards and conditions:

- NORSOK M-710 Annex A – Ageing of elastomeric materials (section 7.2)

- ISO 10423 (API 6A) – Petroleum and natural gas industries – Drilling and production equipment – Wellhead and Christmas tree equipment section F.1.13.5.2 (DD/EE and FF/HH)

- NACE TM0187 – Elastomeric materials in sour gas environments

- ISO 23936-2 Section 7 and Annex A “Petroleum, petrochemical and natural gas industries: Non-metallic materials in contact with media related to oil and gas production – Part 2: Elastomers

These are standard tests. PPE has however gone further, with high concentration testing at 25% H2S rather than the minimum requirement of 2%. These higher concentrations are more representative of real-world conditions, and give a better representation of the efficacy of Perlast® in situ.

Perlast® seals for oil and gas applications

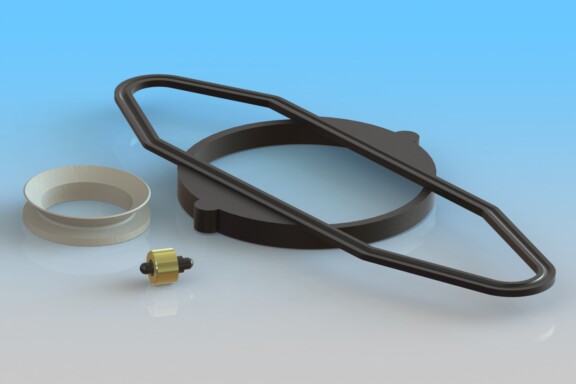

Elastomer sealing components made from Perlast® are engineered for long term reliability in oilfield applications. This minimises the risk of unscheduled downtime and loss of production. Available seal profiles include:

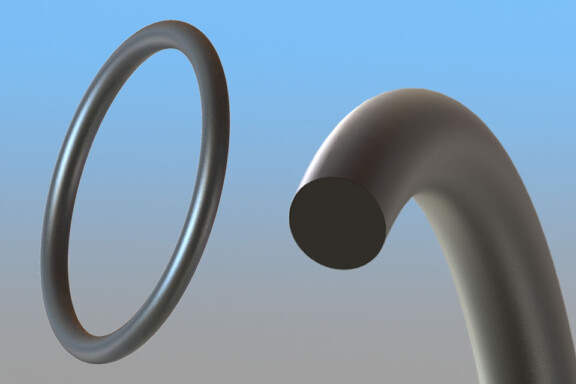

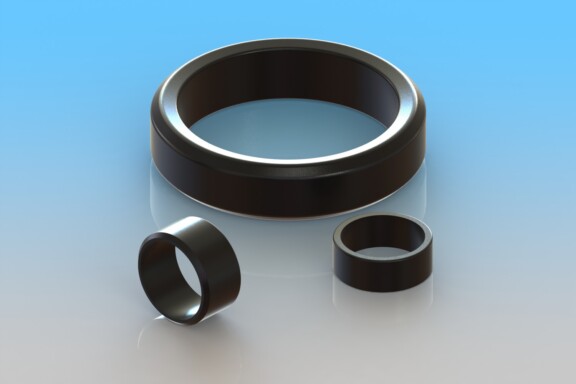

Elastomer O-Rings

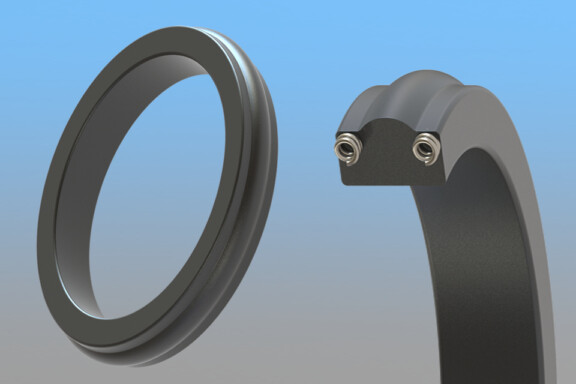

Spring Seals

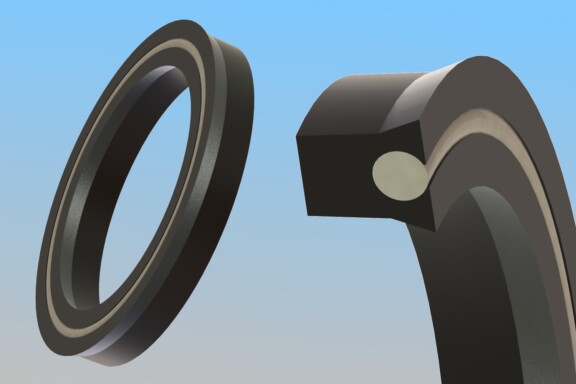

T-Seals

Lip Seals

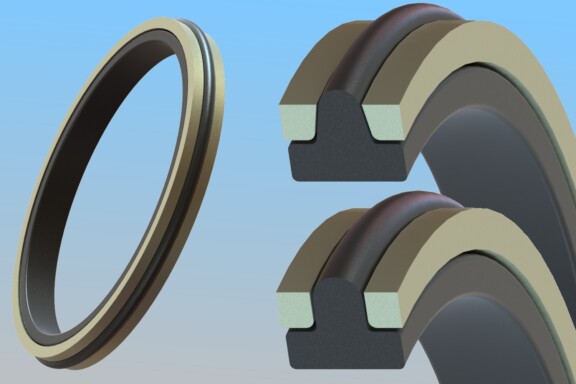

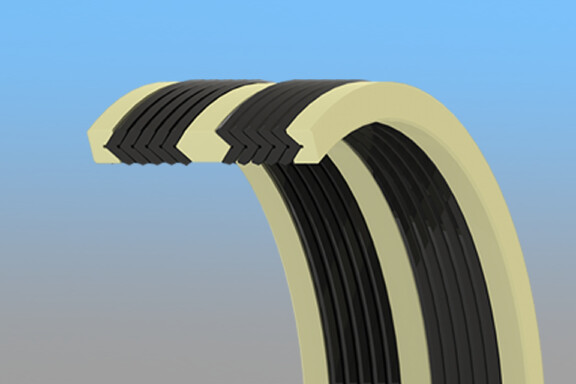

Chevron Stacks

Custom Seals

FS Seals

Production Packers

Resources

Below are some of our most popular downloads relating to Perlast® O-rings and seals for oil and gas applications.

If you require further information on any sealing topic, check out our Resources section.

- What is RGD, and why is it a risk to elastomer seals?

- Webinar: The facts about compression set

- Video guide: What is compression set?

- Benchmarking data: How does Perlast® compare to other FFKM materials?

Looking for more technical detail? Check out our Resources & Tools.

Need more help? Speak to one of our experts today.

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.