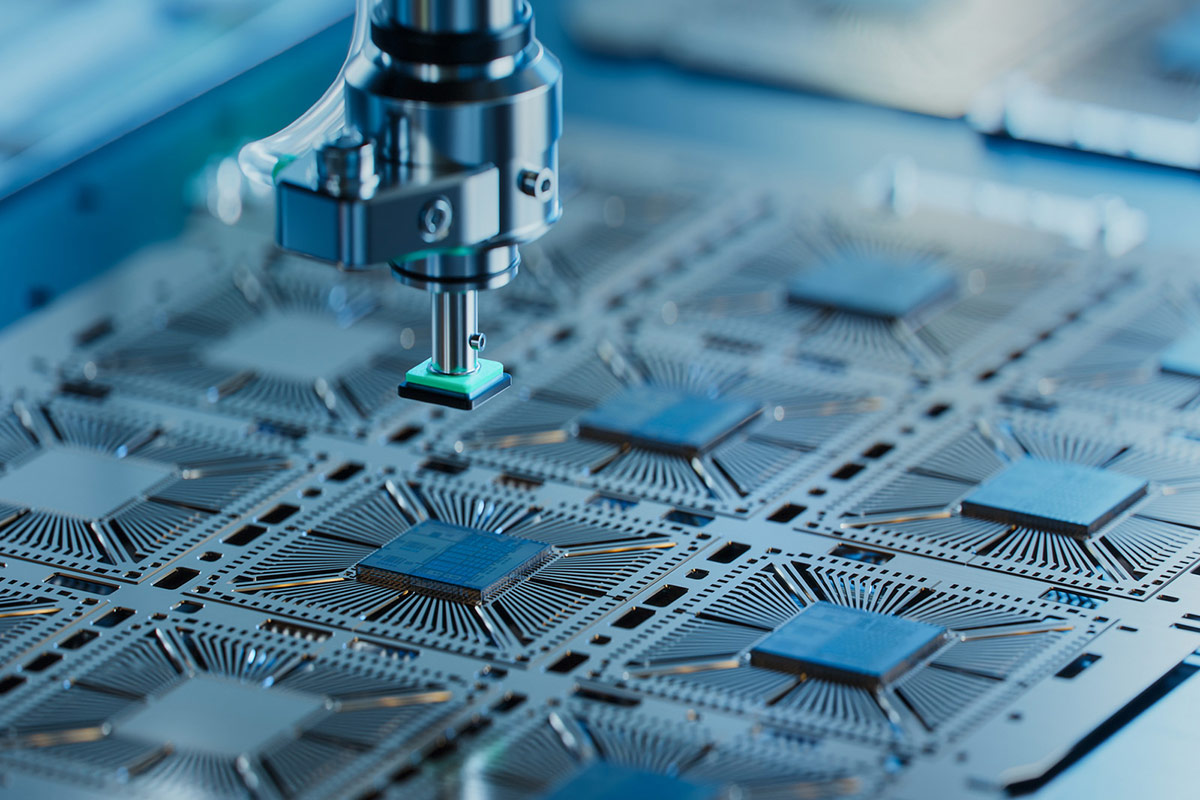

Wet Chemical Processes

Wet chemical process sealing is involved in the processing of wafers and substrates, and requires specialist sealing materials with exceptional chemical resistance and purity.

These processes include electro or electroless chemical deposition.

PPE’s range of seals for wet chemical processes do not contribute organic or trace metallic contamination to the cleaning or stripping fluids.

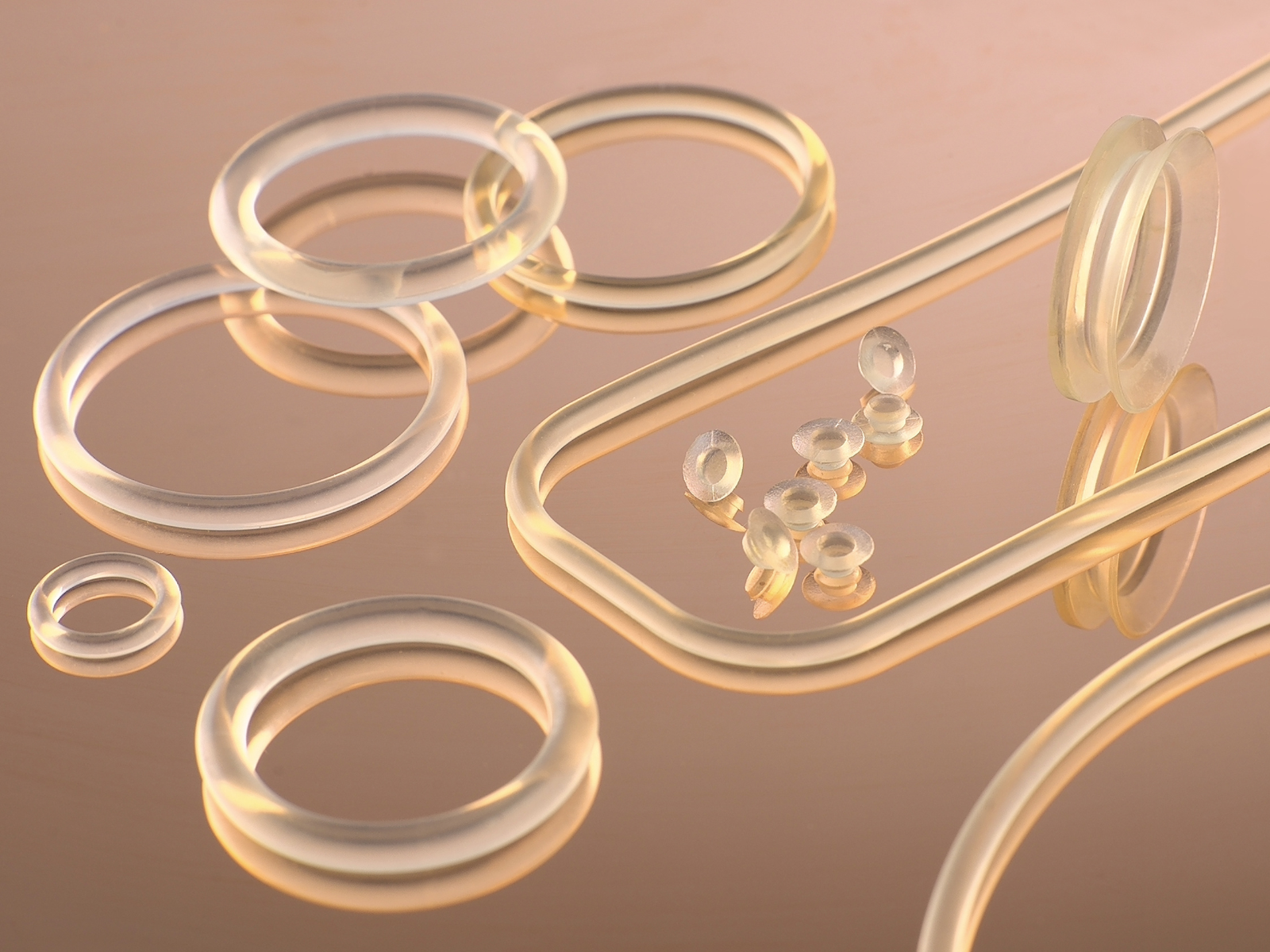

Sealing for wet chemical processes

Wet chemistry is used in two key areas:

- The removal of organic, oxide, or metallic and ionic contaminants at various stages of the manufacturing process. Processes include RCA or SC1 or SC2 cleans, and resist wet strip.

- Application of copper in the interconnect or 3D packaging requires electro chemical deposition or electroless chemical deposition.

The appropriate choice of PPE recommended sealing materials and products can lead to:

- Cost optimized recommendation, dependent on application

- Low erosion rates

- Low trace metal contamination

- Low particle release rates, where critical

- Low pinholes in thin bonded elastomer material applications

- Minimized impact on device yield and electrical yield

- Minimized copper plate up in ECD

- Reduced cost of consumables (CoC)

Recommended materials

The table below indicates recommended and compatible elastomer material grades. Primary grades are geared towards critical system/tool locations.

For further guidance on appropriate choices for wet chemical process sealing, get in touch with our experts for application-specific advice.

| Process/application | Temperature range | Process media | Primary materials | Compatible materials |

|---|---|---|---|---|

| Cleaning / Etching | 25 – 150°C (77 – 302°F) | UPDI, Piranha, SC1, SC2, O3, HF (49%), H3PO4, HNO3 | G80A, G67P, G75M | G74P, G100XT |

| Photolithography Resist strip | 25 – 125°C (77 – 257°F) | H2SO4 + oxidant, organic acids, NMP, Amines | G80A, G67P, G75M | G74P, G100XT |

| Copper Plating ECD | 25 – 100°C (77 – 212°F) | CuSO4 solution H2SO4, H2O2 | G80A, V75SC |