Thermal Processes

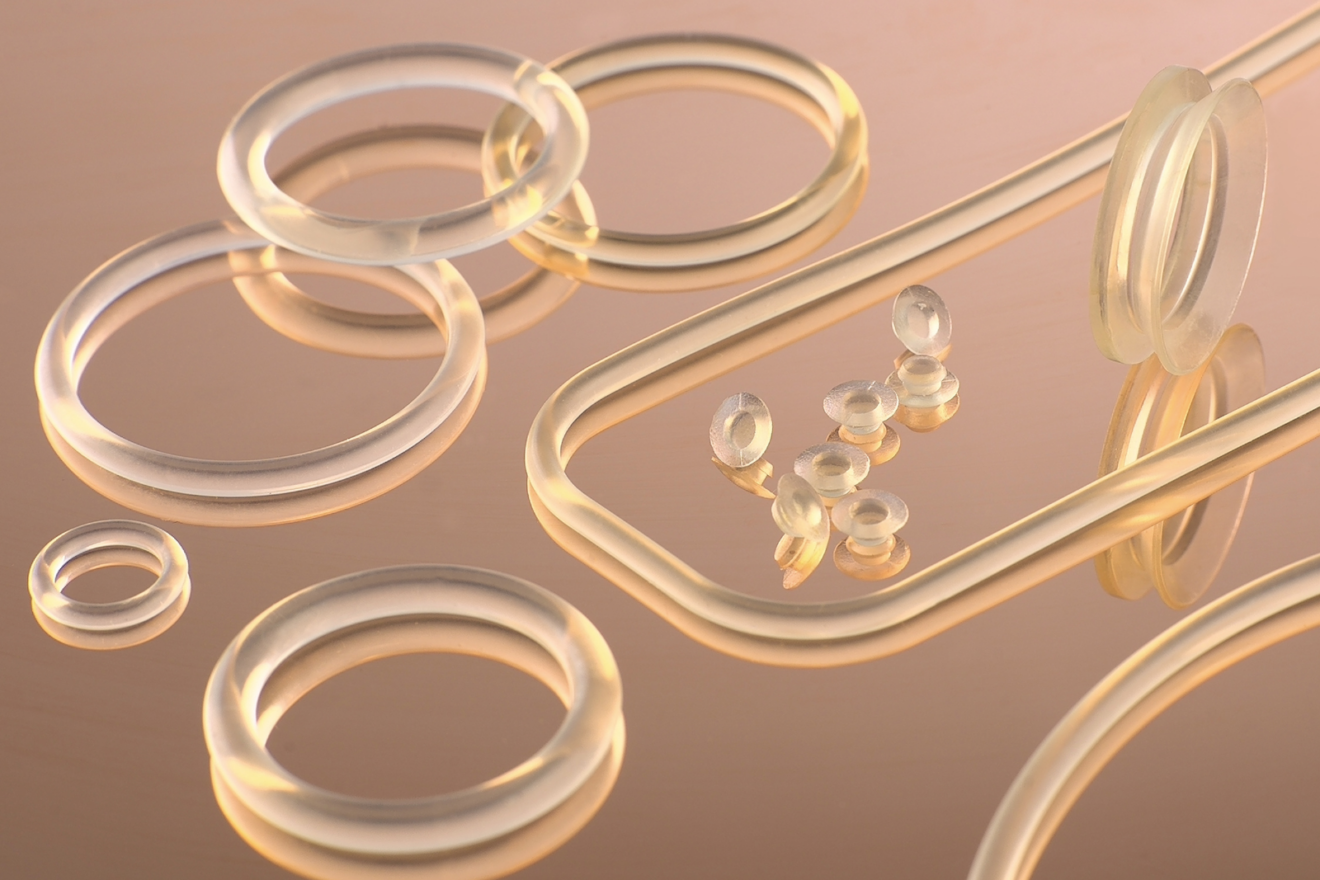

Thermal based applications need sealing materials with good mechanical properties, such as low compression set or compression stress relaxation, in addition to very specific chemical resistance requirements.

These processes often include the use of oxygen, ozone, or a combination of ozone and high energy UV radiation – such as applied to transistor strain engineering, FCVD, and low k processing.

We manufacture bespoke components for:

Metal CVD

ALD

LPCVD

SACVD

Oxidation Diffusions

UV Cure

RTP and

Thermal Oxidation

Benefits of PPE recommended products:

Processes such as ALD, LPCVD, SACVD, annealing and oxidation require seal materials able to withstand long term high temperatures.

Making the appropriate choice of PPE material for thermal processes will result in:

- Cost optimized recommendation dependent on application

- Low compression set

- Longer lifetime in aggressive UV cure regimes

- Low erosion rates

- Low trace metal levels where critical

- Low particle release rates where critical

- Minimized impact on device yield and electrical yield

- Reduced cost of consumables (CoC)

Recommended materials for thermal processes

The table below indicates recommended and compatible elastomer material grades. Primary grades are geared towards critical system/tool locations.

For further guidance on appropriate sealing choices in thermal process environments, get in touch with our experts for application-specific advice.

| Process/application | Temperature range | Process media | Primary materials | Compatible materials |

|---|---|---|---|---|

| Metal CVD ALD LPCVD | 25 – 300°C (77 – 572°F) | Organic precursors, WF6, TiCl4, SiH4, SiHCl3, SiH2Cl2, SiCl4, Ar, N2, H2, NH3, HF, HCl, F2, Cl2, CIF3, NF3, H2O vapour, O2, O3 | G7HA | G75H, G70H, G75B |

| SACVD | 25 – 300°C (77 – 572°F) | TEP, TEBO, TEOS, O3, O2, N2, NF3 | G7HA, G65HP | G70H, G75B, G75H |

| Oxidation Diffusion | 100 – 300°C (212 – 572°F) | N2, O2, H2O, POCl3, BBr3, PH3, B2H6, HCl, Cl2 | G7HA, G75H | G65HP, G70H, G75B |

| RTP andThermal Oxidation | 100 – 300°C (212 – 572°F) | IR radiation, O2, Steam | G65HP, G75B | G7HA, G75H, G70H |

| UV Cure | 100 – 300°C (212 – 572°F) | N2, Ar, O2, O3 | G75H, G70H | G76W |