NACE Certified Elastomers

NACE certified elastomers designed and manufactured to face the harsh operating conditions of upstream exploration and production applications.

NACE International was established in 1943 as the “National Association of Corrosion Engineers.” Since then, NACE International has become the global leader in developing corrosion prevention and control standards, certification and education for oil and gas production, chemical processing and refining industries.

There are two NACE standards focused on elastomer materials used for O-rings and seals:-

- NACE TM0187 – Elastomeric materials in sour gas environments

- NACE TM0297 – Effects of high temperature, high pressure carbon dioxide decompression on elastomeric materials.

NACE TM0187 provides a test method that measures the ability of elastomeric materials to withstand static exposure to elevated pressure and vapor-phase sour gas environments (e.g., gaseous hydrocarbons with hydrogen sulfide) and is not designed to be an immersion or functional test. It is designed for testing O-rings or specimens of elastomeric vulcanites cut from standard sheets.

NACE TM0297 presents test procedures to measure the effect of rapid depressurization from elevated pressures and temperatures in dry CO2 environments on elastomeric materials. Includes sections on the preparation of test specimens and equipment to be used, test procedures to be followed, and procedures for reporting results.

NACE certified materials

PPE offers a number of material grades that have been tested and certified to NACE standards, including HNBR, FEPM, FKM and FFKM. This comprehensive range gives engineers the opportunity to match a sealing material to their operating environment according to temperature, pressure and chemical media.

Browse our material range of NACE TM0187 and NACE TM0297 certified materials.

Test certificates can be downloaded for each material in the Resources section.

Check out RGD resistant elastomers and Sour gas resistant elastomers for details of additional certification.

How can we help? Contact us to discuss your NACE sealing requirements.

Perlast

expand_moreThe ultimate perfluoroelastomers for sealing applications where chemical resistance and high temperature performance are critical.

Perlast ICE

expand_moreExceptional perfluoroelastomers for extreme low temperature sealing applications.

EnDura

expand_moreThe ultimate range of elastomers for sealing applications in the world’s most aggressive high pressure environments.

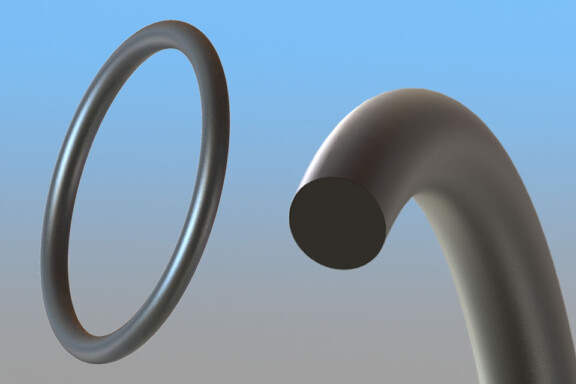

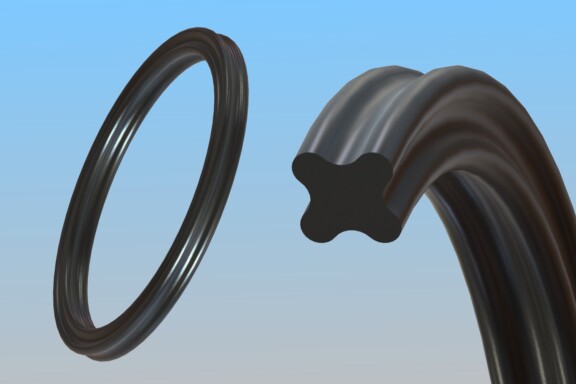

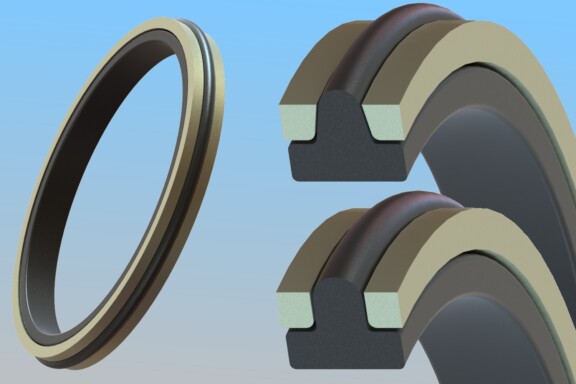

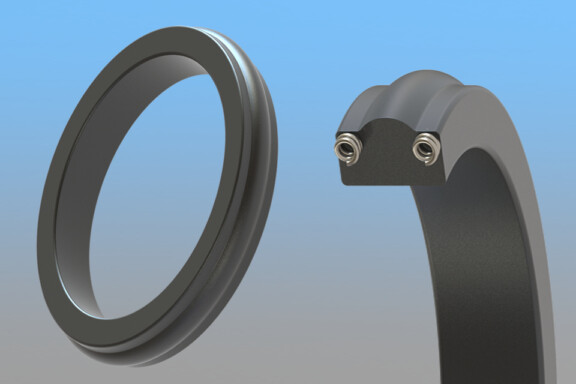

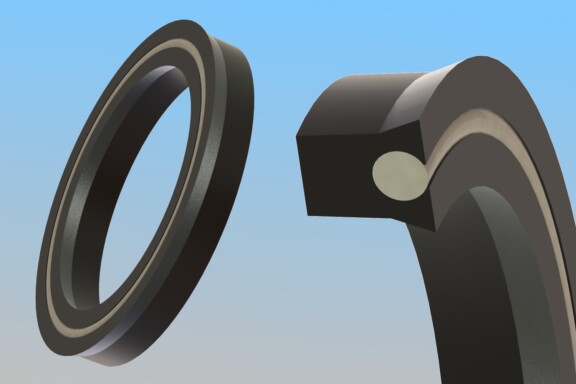

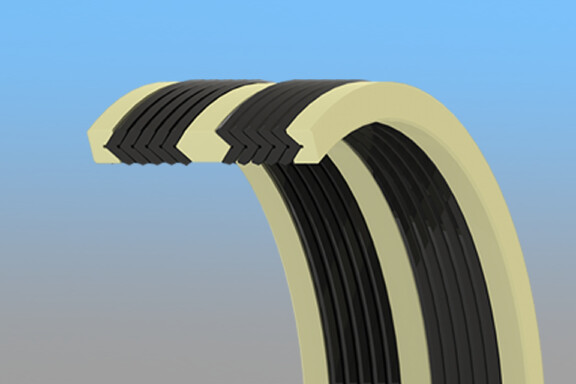

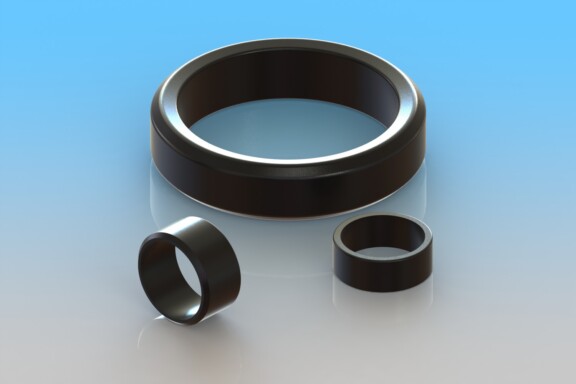

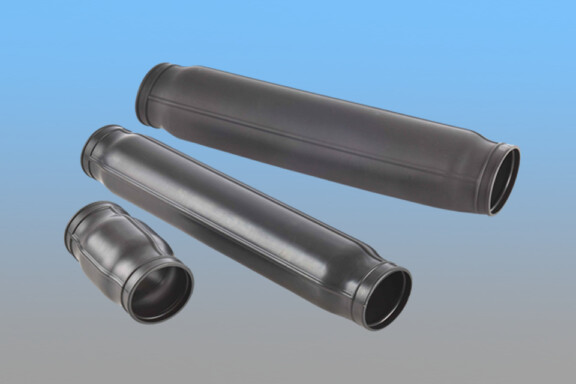

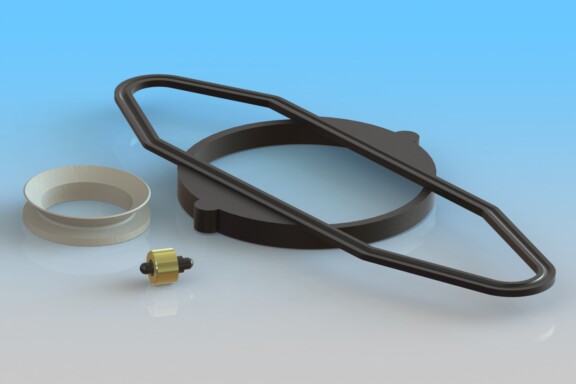

Products

PPE’s NACE certified elastomers can molded into infinite shapes and profiles to suit any application.