Packing Elements

Packing elements are an essential component of well completions (production and injection) and well intervention tools. They are used to seal the annular space between the tubing string and wellbore.

The tool assembly incorporates a means of securing the packing element against the casing or liner wall, such as a slip arrangement, and a means of creating a reliable hydraulic seal to isolate the annulus, typically by using an expandable elastomeric element.

Packing elements are classified by application, setting method and possible retrievability.

Elastomeric Packing Elements

Elastomeric packing elements are used within the packer assembly. They are specially designed to withstand hostile downhole environments and produce the required isolation in oil wells seen in exploration, drilling, and well-service applications. This critical downhole sealing device is used in almost every completion to isolate the annulus from the production conduit, enabling controlled production, injection or treatment.

We supply a wide range of elastomeric packing elements for packing tools including:

- Retrievable Packing Elements

- Permanent Packing Elements

PPE packing elements are engineered to face the harsh operating conditions of upstream exploration and production applications.

About Packing Elements

Elastomeric Packing Elements expand_more

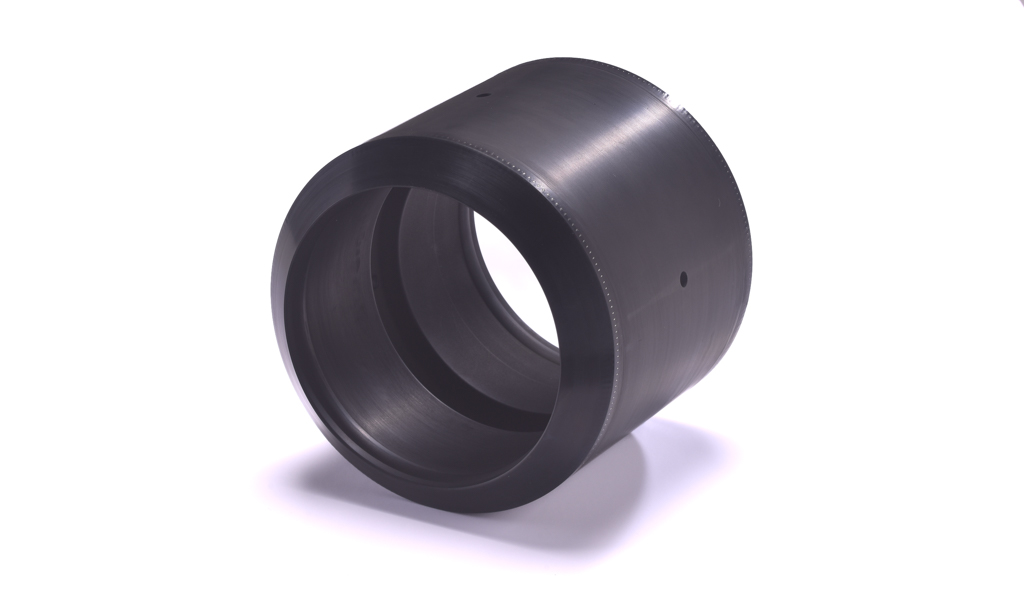

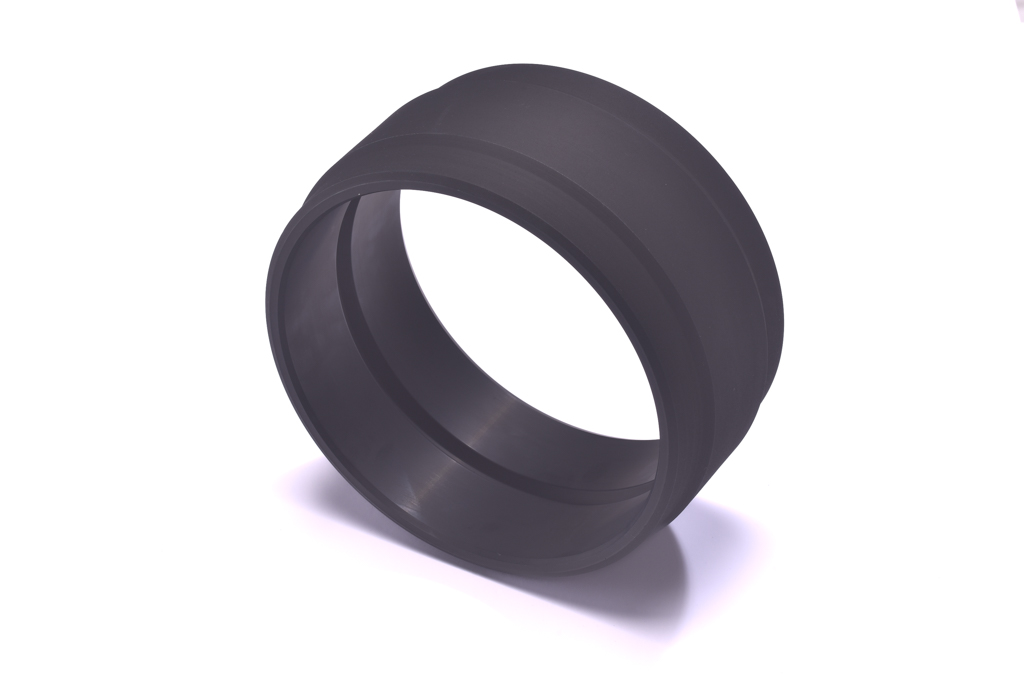

Moulded Packer Elements are elastomeric seals that are used to provide a seal between the outside of the production tubing and the inside of the casing or liner. Packers are annular seals and are required to seal against rough and corroded surfaces with large extrusion clearances and are subjected to very high strains. The service requirements mean that the correct balance between EOB and modulus at temperature is of prime importance when selecting materials, they will typically have higher moduli than typical O-ring elastomers.

Packers are often used in sets of multiple elements (typically 3 with the end elements and middle elements being of different geometry and often of a different hardness material). The cross-sectional profile of packer element varies, and some are complex having co er chamfers, radii, bevels and undercuts on the ID face.

Typical Applications expand_more

- Cementing squeezing

- Formation fracturing

- Well testing

- Well bore cleaning

- Well intervention and servicing

- Completion and production tools

- Artificial lift

Application Challenges expand_more

- Temperature extremes

- High pressures

- Extrusion resistance

- Corrosion resistance

- Chemical compatibility including H2S

- Abrasion resistance

- Large clearances to be sealed

Resources

Take a look at some helpful resources to support you in identifying your optimal sealing solution.

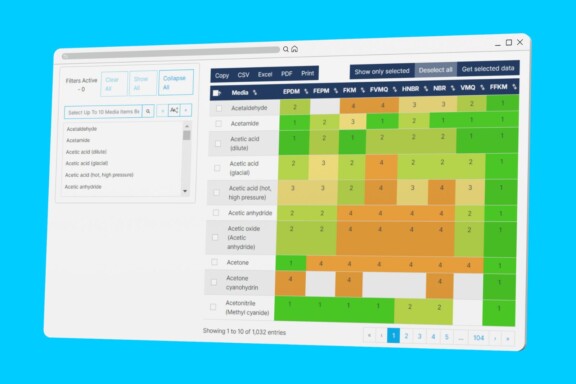

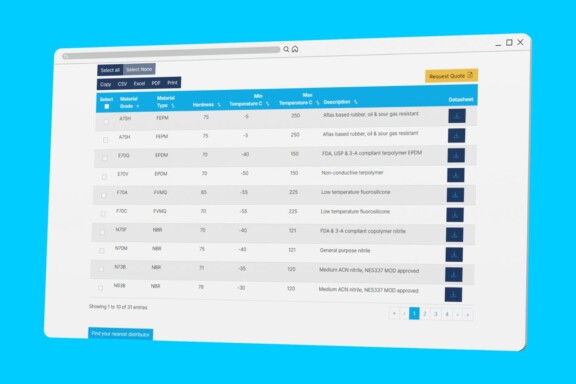

Elastomer Compatibility & Rubber Chemical Resistance Guide

PPE material grades selection tool

Video-Webinar library

Why do O-rings fail

This site is protected by reCAPTCHA and the Google Privacy Policy and Google Terms of Service apply.