Food Dairy Water

Food contact seals are used in food and dairy production environments and potable water systems.

They are required to deliver exceptional sealing performance and long-term reliability, without compromising on the safety of consumers.

Exceptional sealing solutions for the most challenging food, dairy, and water applications.

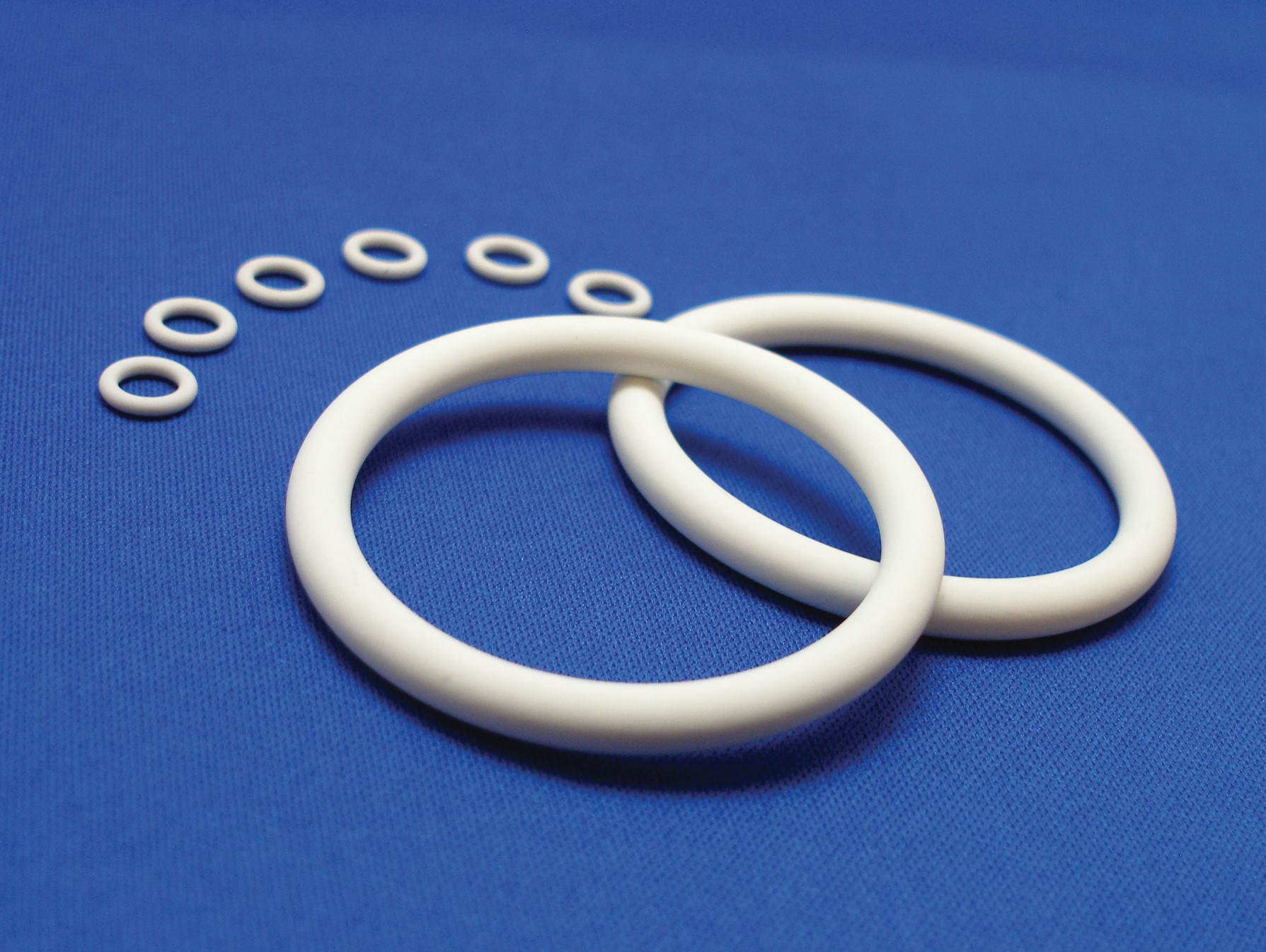

Food contact seals

Our sealing specialists are experts in the development and manufacture of chemically resistant food grade O-rings, seals, and gaskets, for use with aggressive media seen in Clean in Place (CIP) and Sterilization in Place (SIP) practices, and high temperature steam.

PPE’s food and dairy material grades have been engineered to provide high performance with excellent mechanical capabilities, combined with thermal and chemical resistance. Elastomers are available in several grades compliant with the requirements of:

- Food and Drug Administration (FDA): EPDM, NBR, Silicone, FKM, FFKM

- Bundesinstitut für Risikobewertung (BfR): EPDM, Silicone, FKM, FFKM

- Chinese Standard GB 4806.11-2016: Silicone

- 3A 18-03 Sanitary Standards (3A): EPDM, NBR, Silicone, FKM, FFKM

- Spain Royal Decree 847 of July 2011: Silicone

- French Decree of 25 November 1992: Silicone

- EC Regulations 1935/2004 and 2023/2006: NBR, EPDM, Silicone, FKM, FFKM

- WRAS (BS 6920) potable water: EPDM, Silicone

- United States Pharmacopeia (USP Class VI): EPDM, Silicone, FKM, FFKM

Additionally, PPE has pioneered the development of Detectaseal®, a range of metal-detectable elastomers safeguarding against contamination events.

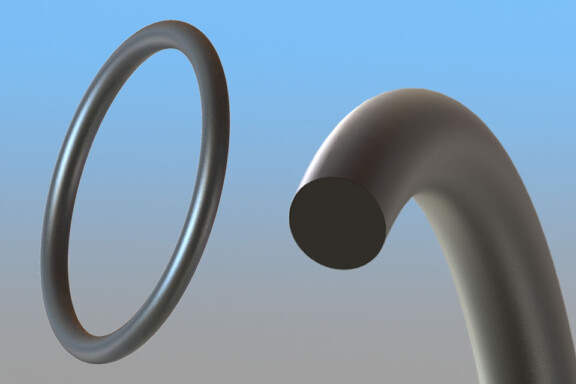

Food grade O-rings

PPE offers a range of food-safe O-rings in elastomer materials compliant with the aforementioned standards.

Elastomer O-Rings

RJT O-Rings

DIN11864 O-Rings

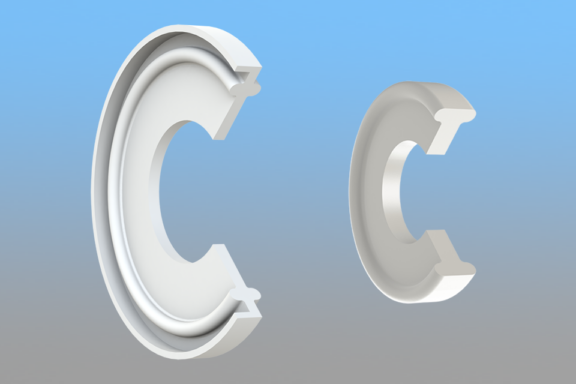

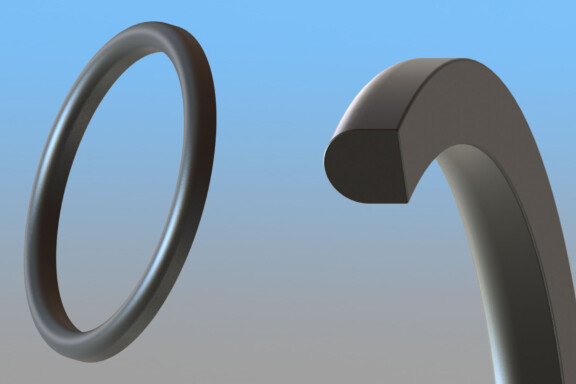

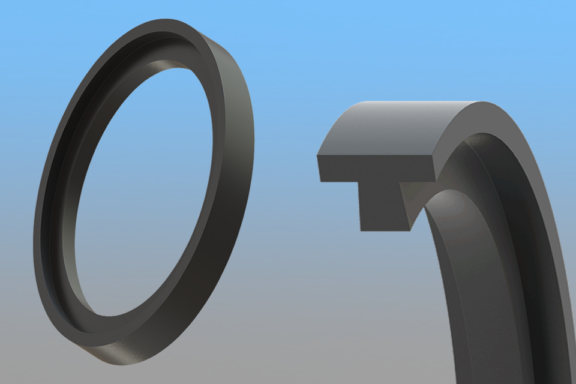

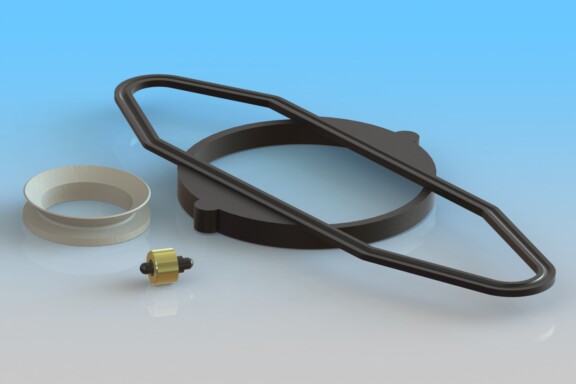

Food grade gaskets and seals

PPE is a specialist in high performance food grade gaskets, seals, and custom rubber components, designed specifically for the challenges of food, dairy, and water industries.

HyClamp™ Sanitary Gaskets

HyClamp™ Mini Gaskets

DIN11851 D-Seals

IDF Gaskets

SMS Seals (SS 1149)

Custom Seals

Potable water seals

PPE has a selection of WRAS approved elastomer materials certified for use in potable water systems.

Our sealing specialists have decades of experience in food grade rubber manufacturing to European Hygienic Equipment Design Group (EHEDG) guidelines. These guidelines look beyond the seal material, and consider the seal in its operating environment. PPE routinely uses Finite Element Analysis (FEA) simulation techniques to develop hygienic seals which do not pose a contamination risk through their potential to ‘trap’ particles or bacteria.

Expert sealing support

With food and pharmaceutical sealing, materials need to demonstrate a broad chemical compatibility profile, high temperature resistance, abrasion resistance and the capability to withstand aggressive cleaning regimes. Precision Polymer Engineering molds components from materials which are certified and compliant with various industry standards, including FDA, 3A Sanitary Standard 18-03, WRAS, EC1935-2004 and EC2023-2006.

Across an extensive product range of high performance food grade O-rings and seals, PPE can engineer a sealing solution tailored to the precise nature of your own problem. Working collaboratively with customers, our engineers can design custom parts and sealing solutions to satisfy requirements specific to food and pharmaceutical applications, optimizing your operations and safeguarding your consumers.

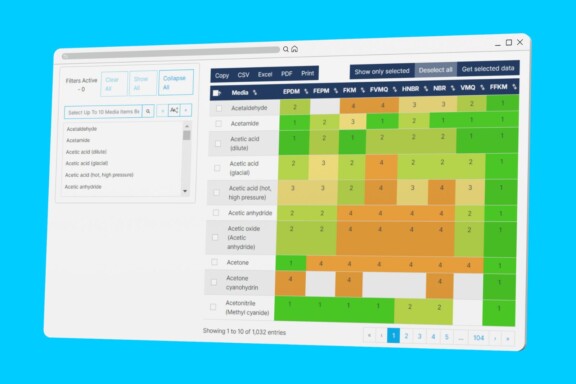

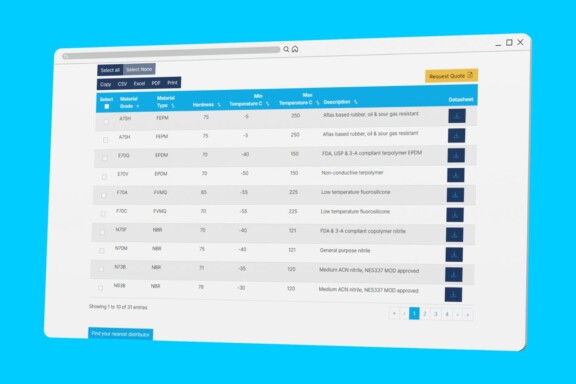

Elastomer Compatibility & Rubber Chemical Resistance Guide

PPE material grades selection tool

FAQs

What is a food grade gasket? expand_more

Food grade gaskets are seal profiles used in food, beverage, and dairy production to prevent contamination and maintain the sterility of consumable products.

They are used in a wide range of process equipment, from blenders and mixers through to packaging machinery.

Materials used in the manufacture of food grade gaskets, like Perlast® at PPE, must comply with a series of strict regulations such as the FDA and USP Class VI.

What is a food safe seal material? expand_more

Sealing materials used in food process environments need to be both fit for their intended use, and not pose any health risk to the consumable product.

This means that the sealing material must be resistant to degradation from not only the process media, but also aggressive chemicals and temperatures typical of industrial cleaning regimes.

Food safe seal materials can demonstrate they are fit for purpose through compliance with FDA and USP Class VI regulations.

What is the best food grade O-ring material? expand_more

Food grade O-rings need to demonstrate excellent resistance to high and low temperatures, aggressive chemicals, and rigorous mechanical stresses – while ensuring the total safety of the consumable product.

Depending on the process media, different materials can perform to a high standard, but may have notable weaknesses in other environments.

Perfluoroelastomer (FFKM) material grades – like Perlast® – maintain exceptional sealing effect under all conditions, for total peace of mind in any food production or process environment.

Need more help? Speak to one of our experts today.

Looking for more technical detail? Check out our Resources & Tools.

Resources

Browse our key resources for food contact sealing solutions, including videos, animations, brochures and webinars.

For our full range of support material, visit our Resources page.