Why do O-rings fail

A brief guide to O-ring failure modes.

There are many reasons why O-rings fail, this brief guide provides details of some of the most common failure modes (there are additional failure modes not covered here).

At Precision Polymer Engineering, we have spent decades developing innovative elastomer materials able to resist the most challenging sealing environments. If you would like further assistance please contact our sealing experts who will be happy to help diagnose the problem and suggest possible solutions.

Common reasons for O-ring failure

Abrasion

Visual indications: The sliding contact faces of the O-ring have a grazed surface, with excessive wear there may be deeper lacerations and breaking in places.

Cause: Common in dynamic applications, abrasion occurs from repetitive contact between the O-ring surface and the housing resulting in excessive friction between the two. Improper lubrication or surface finish of the metalwork can exacerbate the risk, as can ingress of abrasive contaminants into the sealing system.

Solution: Ensuring the correct lubrication for the sealing system is important, PPE can offer a range of O-ring sealing materials with improved abrasion resistance. Our engineers can also advise on the correct surface finish for the metalwork. Ingress of contaminants can be reduced through the use of wiper or scraper rings.

Chemical attack

Visual indications: Dependent on the chemical media being sealed, the O-ring may exhibit a number of signs including blisters, cracking, a change in hardness, or discolouration.

Cause: Some chemicals will react with certain elastomers. More often than not this results in an increase in cross-link density, resulting in a hard and brittle material, with a reduced ability to provide a reaction force. Chain scission is also possible, resulting in a reduced strength. Occasionally cross-link density can reduce, resulting in a softer tacky material, which leads to a loss of its original shape and integrity.

Solution: Correct elastomer material selection is vital to ensure the seal is compatible with the application media. Chemical attack is accelerated at elevated temperatures and when elastomer seals are under stress, as a result of, for example, excessive stretch or squeeze, and mechanical conditions. PPE engineers can recommend the most appropriate sealing material based on your application parameters. For the ultimate in chemical resistance combined with high temperature capability, ask about our Perlast® perfluorolastomers (FFKM).

> Check the chemical compatibility of the main elastomer material types using our online guide.

Chemical swell

Visual indications: The O-ring appears larger than its original dimensions. This may be consistent across the whole seal or in localized areas that have been exposed to the chemical media.

Cause: Swell is caused by the ingress of media into the elastomer, as the result of a chemical similarity between the compound and the media. The increased seal volume can lead to gland fill, extrusion and loss of sealing. Chemical swell can also result in a loss of physical properties such as tensile strength.

Solution: Switch to an elastomer sealing material with proven resistance against the chemical environment. PPE sealing experts can help you identify a material which will deliver lasting sealing performance in the chemical media within your application.

> Check the chemical compatibility of the main elastomer material types using our online guide.

Compression set

Visual indications: The cross-section of the O-ring becomes less circular with flattened surfaces that have taken the shape of the groove/gland. The O-ring has taken on a permanent ‘set’ meaning it is unable to recover to its original shape after removal of deforming stresses. ‘Set’ is quantified as a percentage loss in compression compared to the original compression applied.

Cause: Physical and chemical changes can occur to an elastomer at elevated temperatures that result in set. Cross-link density can increase, this results in the O-ring losing its elasticity and ability to return back to the original shape, this is a permanent chemical change. Stresses introduced to the seals at elevated temperatures can be unable to relax when the temperature is reduced, this is often referred to as cold set, this type of set is reversible upon heating. The reduction in cross section results in a lower contact sealing force, which increases the risk of leakage in systems where thermal and pressure cycling occurs. Other causes include improper gland design, volume swell due to system fluid and incomplete curing of the seal during production.

Solution: Selecting elastomer materials with low compression set and/or higher temperature capability will help to extend seal life. Gland design should also be checked to ensure the O-ring is not over-compressed with too much squeeze applied. Cold set can be reduced by using a more flexible polymer structure, this would be reflected in a lower glass transition temperature.

> Watch webinar: The facts about compression set

Extrusion and nibbling

Visual indications: The edges of the O-ring on the low pressure side have a nibbled, chipped or ‘frilly’ appearance. Shaving can occur in severe cases where the surface of the O-ring appears to be peeled off.

Cause: High stresses, usually as a result of high pressures, forces the material into the clearance gap, this process is typically called extrusion. Pulses of high pressure can cause the clearance gap between the mating edges to open and close. This can lead to the O-ring becoming trapped between the sharp edges of the mating surfaces, resulting in physical damage to the seal surface often referred to as nibbling.

Solution: A harder seal material can help, as can the use of backup devices to effectively reduce clearance gaps. Your PPE sealing expert can also advise on the installation of correctly sized O-rings and back up devices for your application, decreasing your clearance gaps and minimizing the risk of extrusion and nibbling.

Installation damage

Visual indications: Damage caused to the seal during installation can often be diagnosed by specific and exact cutting and notching on the seal surface, with all damage restricted to the O-ring surface.

Cause: Installation damage can take a wide range of forms, from ‘skiving’ of the seal with metal components through to damage caused by careless installation of dirty, twisted or improperly lubricated seals. Incorrect sizing of the seal for the application is also a significant factor in installation damage.

Solution: Taking care during the installation of O-rings is key to preventing installation. Covering sharp edges and threads using tape or protective sheaths will prevent nicks to the surface. Ensuring hardware has suitable lead-in chamfers aids the make-up of the hardware, along with suitable lubrication.

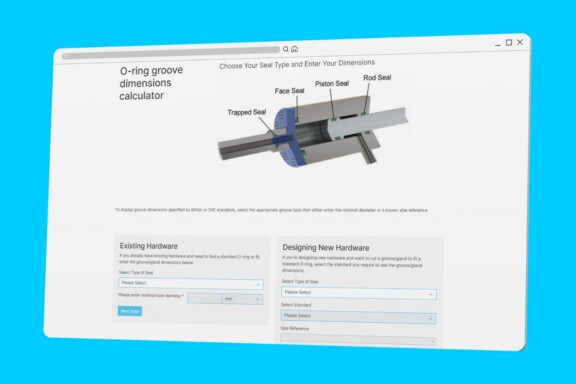

> Look-up O-ring and hardware dimensions against industry standards

Out-gassing

Visual indications: Usually the seal demonstratres no visible change. In extreme cases, shrinkage can be observed.

Cause: Constituent ingredients within the elastomer formulation can be released (volatilized) under vacuum conditions. These constituents can be either a part of the elastomer formulation, the decomposition products of the ingredients or other gasses which are trapped in the polymer matrix during the molding process. In semiconductor applications, out-gassed molecules can cause contamination during wafer processing. In industrial applications it can affect vacuum performance.

Solution: Materials formulated with pure polymers and no volatile ingredients (eg. plasticisers, waxes, etc) provide lower outgassing. Using materials rated to the correct temperature for the application also helps keeping the outgassing at the minimum level.

> Watch video: Causes of elastomer O-ring and seal failure – Outgassing

Plasma degradation

Visual indications: A key marker is an even material loss on the surface of the part which is in contact with the plasma. In some cases powdery residue on the seal surface and discolouration can also be observed depending on the filler type of the material.

Cause: Plasmas consist of extremely high energy ionised gasses and/or radicals which attack the organic backbone of the material and form small molecules or particles. The etching occurs as ion bombardment, along with chemical attack.

Solution: With long term exposure to plasma, seal damage is unavoidable. The chemical compatibility of the material can help to resist damage for longer, improving the lifetime of the seal and reducing the impact of equipment downtime. Ask your PPE sealing expert about Perlast®, Nanofluor® and Kimura® materials which provide plasma resistance that is comparable or superior to many high purity FFKM grades.

> Watch video: Causes of elastomer O-rings and seal failure – Plasma Degradation

Rapid gas decompression (RGD)

Visual indications: The seal surface may be blistered, cracked, marked with deep splits or completely ruptured in the worst examples.

Cause: When elastomer seals are exposed to high-pressure gas at elevated temperatures for a prolonged period of time the gas absorbs into the polymer compound. When the external pressure is reduced, the gas dissolved within the material comes out of solution to form micro bubbles. As the gas expands, it will permeate out of the material. Failure occurs if the rate of decompression and expansion is high, and the trapped gas within the seal expands beyond the materials ability to contain the gas bubbles.

Solution: Increasing the time for decompression and reducing the temperature will typically reduce the risk of explosive decompression (ED) damage, as will choosing an RGD-resistant material. PPE has been an industry leader in the development of RGD-resistant elastomer seals and O-rings – conforming to NACE TM0187, TOTAL GS EP PVV 142 Appendix 8, NORSOK M710 Annex B and ISO 23936-2 Annex B international standards, and improving operational safety and efficiency.

> Watch video: Causes of elastomer O-rings and seal failure – RGD

Spiral failure

Visual indications: The seal demonstrates a tell-tale spiralling pattern around its exterior, with subsequent deep cutting of the seal surface at 45 degree angles where the highest stress levels are apparent.

Cause: Spiralling of an O-ring can occur during dynamic, reciprocating motion, either during installation or in use. The levelling of spiralling is affected by many different factors including, but not restricted to, uneven surface finishes, improper lubrication, friction, installation errors and eccentric components.

Solution: A harder O-ring material is a good starting point for the prevention of spiralling. You might also consider a different seal profile, with PPE X-rings (quad rings) and D-seals proven to resist spiralling without a reduction in seal performance. If a high pressure seal is required, the T-seal provides a robust sealing solution with complimentary backup rings. X-rings, D-seals and T-seals can usually fit existing O-ring grooves/glands.

Thermal degradation

Visual indications: There may be instances of radial cracking on surfaces bearing the highest temperatures. If the seal material is prone to thermal softening, the surface may also become shinier in places. Thermal degradation is often accompanied by compression set.

Cause: The temperature of the application has exceeded the maximum temperature ceiling of the selected seal material or excessive temperature cycling has occurred. High temperatures can increase the cross-link density in elastomers resulting in an increase in hardness and modulus, making them less elastic.

Solution: Selection of a higher temperature elastomer material is the obvious solution. PPE can provide reliable high temperature sealing up to +350°C (+662°F) with its range of Perlast® perfluoroelastomers (FFKM).

Thermal extrusion

Visual indications: There are obvious signs of set with the O-ring no longer having a round profile. A ‘frilly’ edge will be evident on two opposing sides or areas of ‘nibbling’ where sections of the O-ring surface have been damaged. In high pressure applications, the extrusion or nibbling may be held off on the high pressure side and only evident on the low pressure side. The O-ring often takes on the shape of the groove.

Cause: The Coefficient of Thermal Expansion (CTE) of an elastomer is typically much higher than that of the surrounding hardware. This means at elevated temperatures the volume of the elastomer will have increased greater than that of the material surrounding it; therefore at elevated temperatures O-rings can fill the groove and then subsequently extrude into the clearance gaps.

Solution: Groove/gland design should be optimised such that there is sufficient space to accommodate the additional seal volume at high temperatures and avoid ‘gland fill’ – see our online groove/hardware dimensions guide.

> Watch video: Causes of elastomer O-ring and seal failure – Thermal Expansion

UV degradation

Visual indications: The earliest sign on exposed surfaces of O-rings will be discolouration, with excessive exposure in prone materials leading to subsequent cracking and, in extreme cases, disintegration.

Cause: Ultraviolet light exposure on an elastomer material can have a destructive effect. UV light has short wavelength, therefore it has high energy, which can interact with the molecular structure of the exposed side of the elastomer. This generally results in cleavage of the polymer chains and causes cracking on the surface, which will lead to leaking and premature failure.

Solution: Black materials typically resist UV damage better than other colors, fluorinated materials also demonstrate higher resistance. For UV processes used in sterilisation procedures and semiconductor manufacturing, contact PPE for material recommendations.