Spring Seals (S-seals)

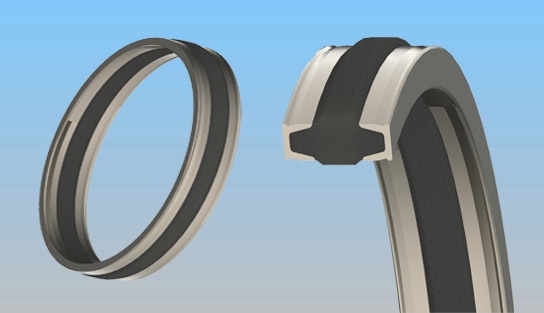

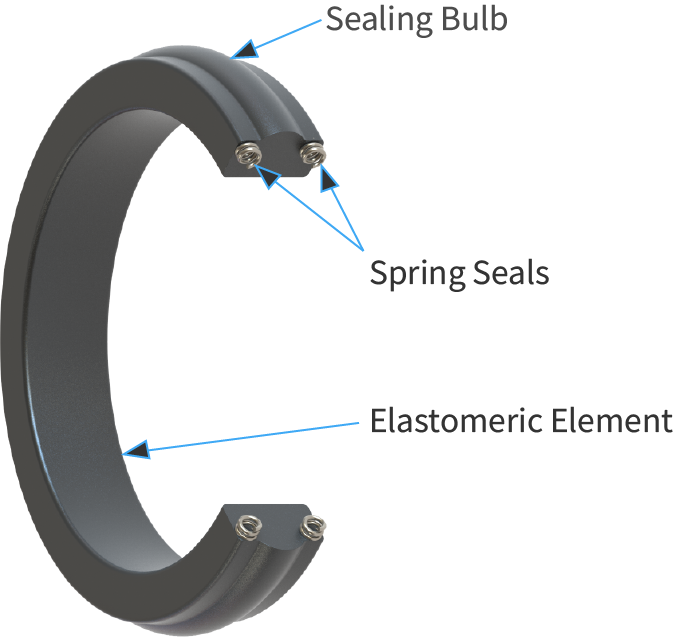

Spring Seal (also known as S-seals and all-in-one T-seals) is a double acting static seal, comprising of a high modulus elastomer and two integrated anti-extrusion springs.

Spring Seal (also known as S-seals and all-in-one T-seals) is a double acting static seal, comprising of a high modulus elastomer and two integrated anti-extrusion springs.

The springs used are manufactured with no initial tension so that the coils are free to open to allow for rubber penetration during molding. The same mechanism allows the spring to respond to pressure fluctuations during operation to close clearances in the metalwork and ensure extrusion of the elastomer is prevented.

Spring seals are symmetrical in their cross section and so they can be used in both rod or piston grooves. Piston type Spring Seals feature an external sealing bulb, or a rod type Spring Seals features an internal sealing bulb.

Steel springs, either Inconel Alloy or Stainless steel 316 offer optimum strength, however PEEK springs are ideal for low wear applications where metal-to-metal contact with the housing is a concern.

FS seals are recommended as an alternative to Spring Seals for use against rough casing and when there is a large clearance between the mating parts of the wellhead. An FS seal typically has a larger cross section than a Spring Seal to increase the sealing force on the casing while the recess in the seal back controls the radial compression on the seal by allowing it to deflect when in contact with a larger or out-of-round casing section.

-

Typical Applications

Most commonly used to effectively seal in applications that are subject to:

- Large clearance gaps

- High pressure (bi-directional)

- Remote hardware makeup

- Restricted access for seal installation

- Chemical attack by oilfield media

-

Materials

Spring Seals include the following elastomers families:

- FFKM - Perlast® and Perlast® ICE

- FKM - EnDura®

- HNBR - EnDura®

- NBR

And the following spring materials:

- Stainless Steel 302

- Inconel Alloy 600

- All combinations of the above elastomers and springs are available in both Piston and Rod variants.

-

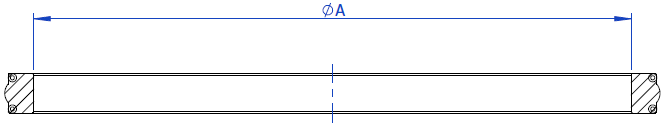

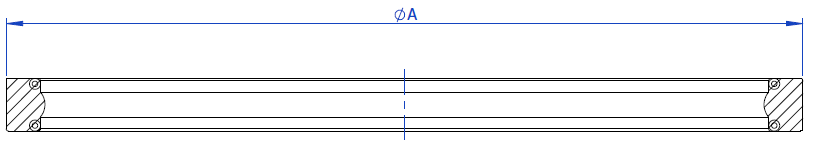

Geometry Detail

Internal Diameter of Piston Type Spring Seal

Internal Diameter of Piston Type Spring Seal Internal Diameter of Rod Type Spring Seal

Internal Diameter of Rod Type Spring Seal

Ask a question

How might we be able to help you?

Other Products for Baker Hughes Oilfield Equipment

Below is a selection of the most common products we supply to the Baker Hughes Oilfield Equipment sector. Click on a specific product to find out further information.