FS Seals

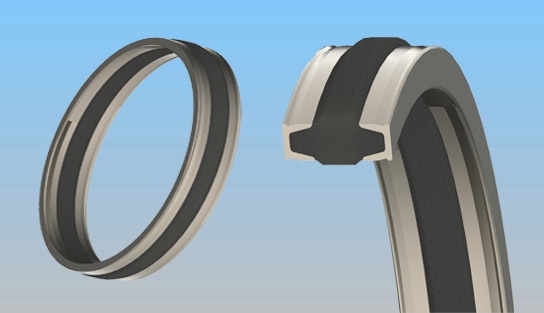

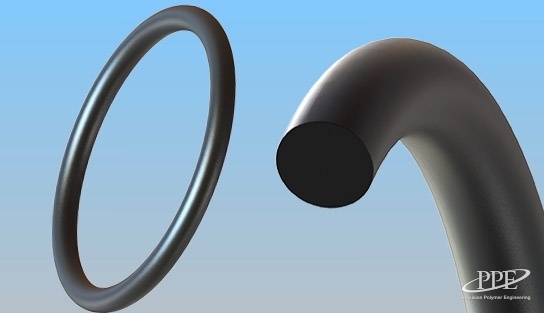

Similar in form and function to a rod orientation Spring Seal, the FS seal is a double acting static seal designed for use as casing and tubing hanger seals in wellheads. FS seals are designed for use against rough casing, with wide dimensional and geometrical tolerances and variable surface finishes, which can result in large clearance between the mating parts of the wellhead.

An FS seal typically has a larger cross section than a Spring Seal to increase the sealing force on the casing while the recess in the seal back controls the radial compression on the seal by allowing it to deflect when in contact with a larger or out-of-round casing section.

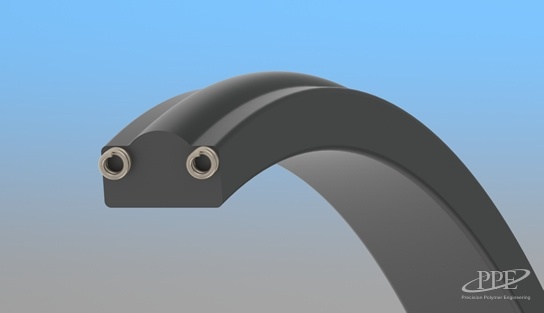

The FS seal is made up of an elastomeric sealing element with molded-in springs to act as anti-extrusion elements. The springs used are open coil and manufactured with no initial tension so that the coils are free to open to allow for rubber penetration during molding. The same mechanism allows the spring to respond to pressure fluctuations during operation to close clearances in the metalwork and ensure extrusion of the elastomer is prevented. Due to the potential for larger clearances in the wellhead, the FS seal springs are of a larger diameter than a corresponding Spring Seal.

-

Materials

FS-Seals are available in the following elastomer families:

- FKM - EnDura®

- HNBR - EnDura®

- NBR

And the following spring materials:

- Stainless Steel 302

- Inconel Alloy 600

All combinations of the above elastomers and springs are available.

-

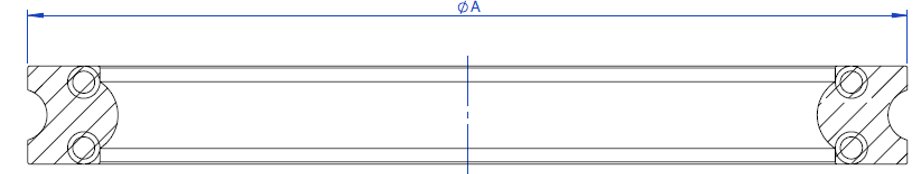

Geometry Detail

Outside Diameter (A) of FS Seal

Outside Diameter (A) of FS Seal -

Standard Sizes

Nominal Casing Size Housing Bore Housing Depth Inch mm Inch mm 2.875” 4.063 103.19 0.835 21.21 3.500” 4.688 119.06 0.835 21.21 4.000” 5.250 133.35 0.835 21.21 4.500” 5.750 146.05 0.835 21.21 4.750” 6.000 152.40 0.835 21.21 5.000” 6.250 158.75 0.835 21.21 5.500” 6.750 171.45 0.835 21.21 5.750” 7.000 177.80 0.835 21.21 6.000” 7.250 184.15 0.835 21.21 6.625” 7.875 200.03 0.835 21.21 7.000” 8.250 209.55 0.835 21.21 7.625” 8.875 225.43 0.835 21.21 7.750” 9.000 228.60 0.835 21.21 8.625” 9.875 250.83 0.835 21.21 9.000” 10.250 260.35 0.835 21.21 9.625” 10.875 276.23 0.835 21.21 9.875” 11.125 282.58 0.835 21.21 10.750” 12.000 304.80 1.000 25.4 11.750” 13.125 333.38 1.000 25.4 11.875” 13.250 336.56 1.000 25.4 13.375” 14.750 381.00 1.000 25.4 13.625” 15.000 381.00 1.000 25.4 14.000” 15.375 390.53 1.000 25.4 16.000” 17.375 441.33 1.000 25.4 18.625” 20.000 508.00 1.000 25.4 20.000” 22.063 560.39 1.563 39.69 24.000” 26.063 662.00 1.563 39.69 * 30.000” 32.063 814.10 1.563 39.69 * 36.000” 38.063 966.80 1.563 39.69 * Larger sizes on a project by project basis

Ask a question

How might we be able to help you?

Other Products for Baker Hughes Oilfield Equipment

Below is a selection of the most common products we supply to the Baker Hughes Oilfield Equipment sector. Click on a specific product to find out further information.