Why are FFKM (perfluoroelastomers) in short supply?

You may be currently experiencing difficulties in obtaining some perfluoroelastomer (FFKM) grades. Here are some of the most prominent factors which, when combined, have created a global supply chain problem which has impacted the entire sealing industry. We’ll also take a look at the steps PPE is taking to supply your FFKM seals with minimal disruption.

The challenges

Shortage of ingredients

Producing FFKM is a complex process requiring highly specified ingredients. If the sourcing of just one ingredient is disrupted due to supply chain issues, FFKM elastomers cannot be produced. There are currently several FFKM ingredients facing an industry-wide shortage. There are some FFKM manufacturers who are reliant on just one or two suppliers for these ingredients. This makes their supply situation the most precarious.

Producing FFKM is a complex process requiring highly specified ingredients. If the sourcing of just one ingredient is disrupted due to supply chain issues, FFKM elastomers cannot be produced. There are currently several FFKM ingredients facing an industry-wide shortage. There are some FFKM manufacturers who are reliant on just one or two suppliers for these ingredients. This makes their supply situation the most precarious.

The situation has been exacerbated by the forced closure of the manufacturing facility of one of the global rubber industry’s key suppliers in Q4 2021, and also a termination of supply from one of their Russian plants in 2022. As a result this supplier has declared a force majeure event.

Sanctions on Russia

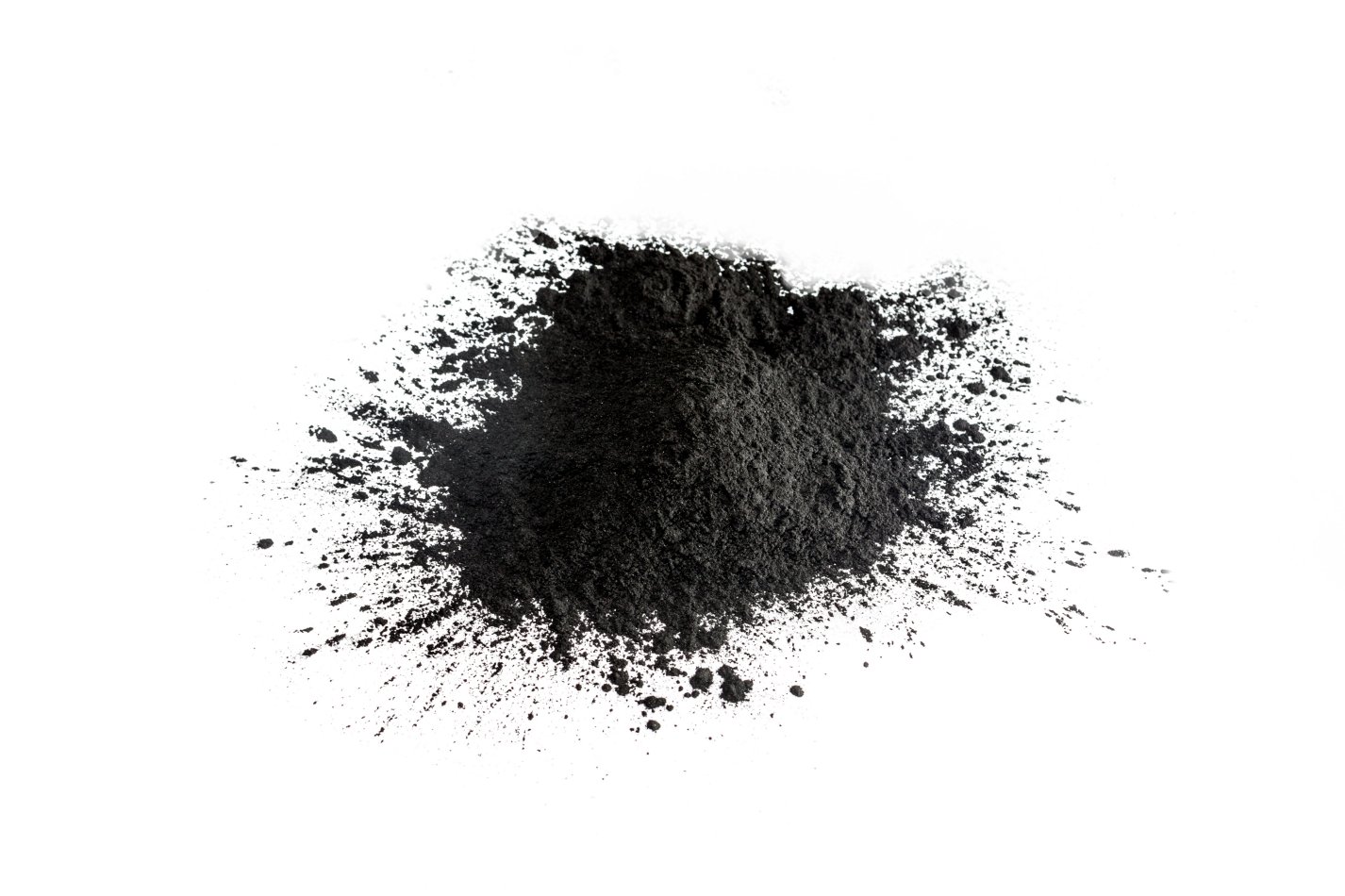

Carbon black is a key ingredient of many elastomer compounds, including FFKM. Russia accounts for almost a third of the global supply of carbon black. Recent sanctions on Russia have resulted in reduced availability, and subsequent price increases for this material from non-Russian sources.

Energy crisis in China

China is currently experiencing a climate crisis, one of the responses to which has been the enforced reduction of power consumption by electricity rationing. Rolling blackouts have been imposed, impacting the production of some key ingredients of FFKM, and compounding the short supply of materials.

Competition with other markets

The huge surge in demand for silicon chips has resulted in the limited supply of perfluoroelastomers being diverted to semiconductor manufacturing. In addition, pharmaceutical equipment needed in the fight against Covid was prioritised, resulting in other industries being left with very little availability.

Impact of Covid pandemic

Personnel absence and reduced staffing levels have affected many suppliers during and after the Covid pandemic. This has resulted in delays and reduced availability of polymers and ingredients. Some suppliers are only just getting back to pre-pandemic output.

How is PPE responding?

PPE acted quickly when supplies were forecast to retract. We maintain close relationships with our material suppliers and collaborate with these key players in order to secure enough material for a continuous supply. The fluoropolymer supply chain is in strict allocation mode across the globe. Thanks to our global outreach and consolidated market presence, we continue to supply our customers, without any major impact on lead-times.

INNOVATION | PERFORMANCE | AVAILABILITY

If you're looking for FFKM alternatives, consider Perlast® from PPE.

Perlast® perfluoroelastomer parts can be manufactured to order in as little as 20 days

(dependant on size, quantity and material grade).

Request a quote or contact us to discuss your FFKM sealing requirements.