T-Seals

T-seals offer an excellent sealing solution for static or reciprocating dynamic applications. T-seals can be designed to retro fit into existing O-ring grooves (both piston and rod orientations) or optimized for specific application requirements.

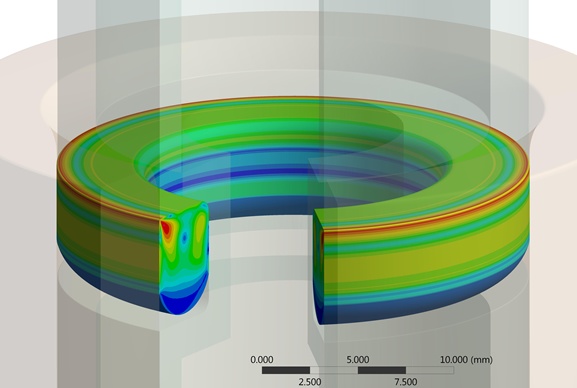

T-seals comprise of an elastomer T-shaped cross section and two backup rings made from an engineering grade plastic, often PTFE or PEEK.

T-seals comprise of an elastomer T-shaped cross section and two backup rings made from an engineering grade plastic, often PTFE or PEEK.

The use of the backup rings allows the T-seal to be used in high pressure applications whilst still maintaining high sealing efficiency at low pressures. The design of the T-seal uses the system pressure to actively energize the backup rings, ensuring efficient extrusion resistance in single and bi-directional pressure applications, both in static and dynamic conditions.

Installation procedures for T-seals are often simplified over other seal designs due to their symmetrical geometry.

As an alternative to T-seals, PPE also manufactures spring seals (sometimes referred to as all-in-one T-seals).

How can we help? Contact us to discuss your T-seal requirements.

Send us your requirements

Share with us your T-seal needs and we'll respond with our best offer.