X-Rings / Quad Rings

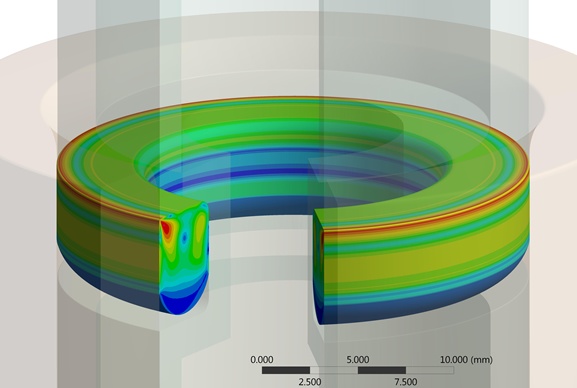

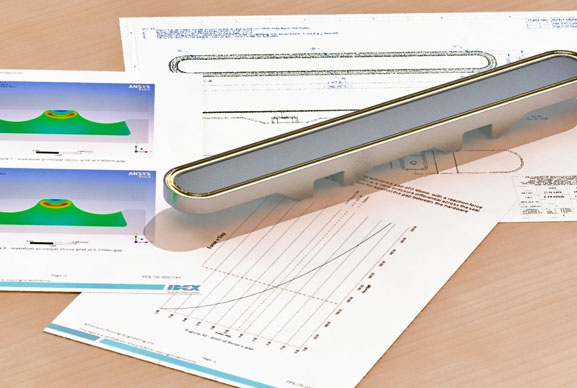

X-rings (also known as quad rings or four-lobed seals) offer an alternative seal solution to O-rings for use in reciprocating dynamic or rotary applications.

They are often used in applications where the seal is required to operate under lower pressure and temperature conditions. Under low pressure, high sealing efficiency can still be achieved with an X-ring as the mold parting line is not coincident with the primary sealing faces.

They are often used in applications where the seal is required to operate under lower pressure and temperature conditions. Under low pressure, high sealing efficiency can still be achieved with an X-ring as the mold parting line is not coincident with the primary sealing faces.

X-rings can typically be retrofitted into existing O-ring grooves with the size often based around the original O-ring size. The square envelope of the X-ring stops the seal from twisting and rolling, preventing spiral failure often seen when O-rings are used in reciprocating applications. X-rings can be manufactured to standard O-ring sizes, as well as custom sizes for specific applications.

X-rings can also offer a reduction in friction as trapped media between the lobes can provide lubrication to the sliding sealing face. For low pressure applications, the combination of a low modulus material and small cross section can help to reduce friction. In high pressure applications, the friction can be reduced by selecting a higher modulus material with a reduced coefficient of friction.

High performance materials

With an unrivalled range of elastomer materials available, PPE has an elastomer for every application, with performance characteristics that meet high temperature, high pressure and aggressive chemical applications.

For X-rings used in food, dairy and pharmaceutical applications PPE offers a variety of elastomer material grades compliant with many international requirements such as FDA, USP Class VI, WRAS and 3-A in addition to metal detectable X-rings, all of which are free from Animal Derived Ingredients.

How can we help? Get in touch to discuss your X-ring requirements.

Send us your requirements

Let us know what you need and we'll respond with our best offer.