Engineered for every extreme

The reliable FFKM sealing choice for critical applications

Why choose Perlast® FFKM?

Perlast® FFKM is manufactured exclusively by Precision Polymer Engineering (PPE), delivering high performance sealing with over 20 years of reliability in service.

At Precision Polymer Engineering we have the right product for your application, helping you:

Reduce maintenance costs

Improve reliability

Outstanding Mechanical Properties

Technical Support

Perlast® parts include:

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut

Perlast® Key Features & Benefits

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Extreme Temperature Capability

- Comprehensive Cold²Hot FFKM capability from -46°C (-51°F) up to +325°C (617°F).

- Reliable and consistent performance.

Available to Order Now with Short Manufacturing Lead-times

- Perlast® FFKM has very short manufacturing lead-times.

- PPE can manufacture Perlast® O-rings and seals in approximately 30 days*.

- If we have stock, components can be shipped the same day.

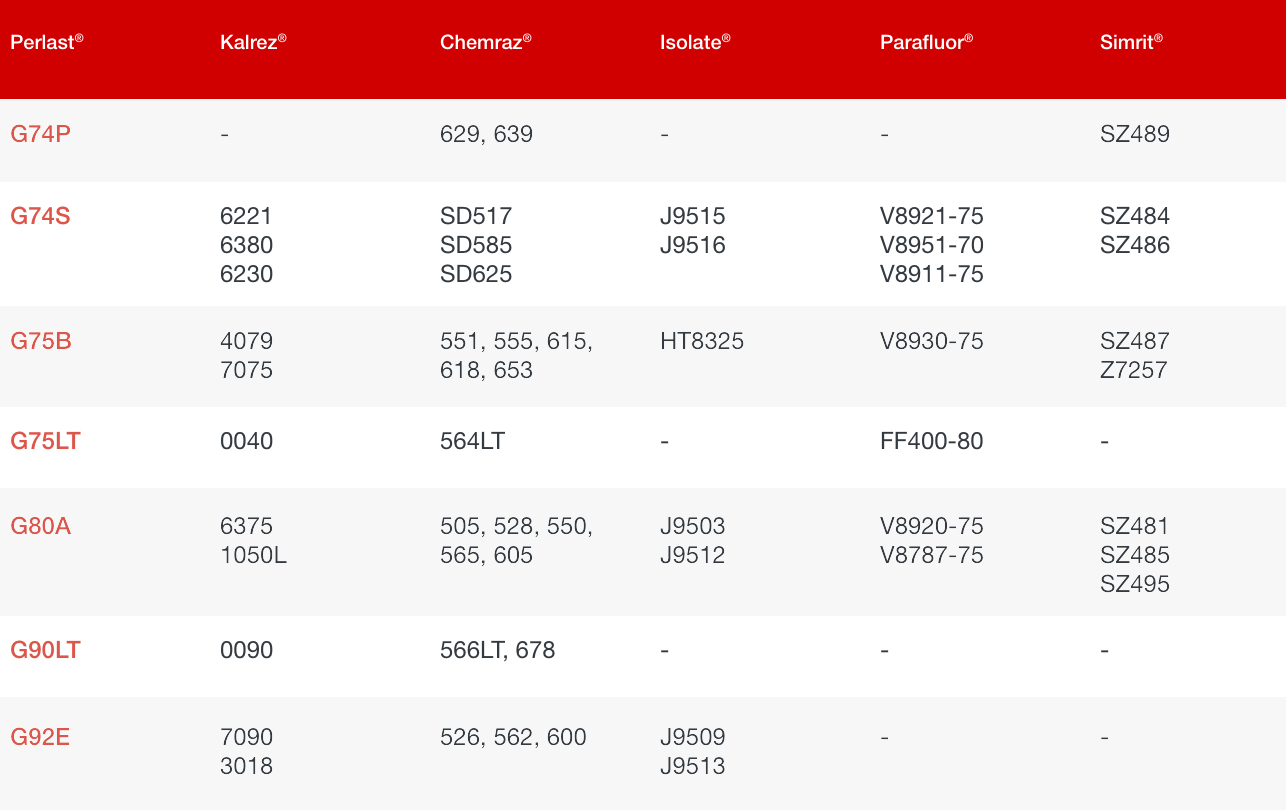

Alternative to Kalrez® and Chemraz® FFKM

- Perlast® mechanical seals are a quality option and deliver consistent high performance.

- Perlast® mechanical seals use high-quality ingredients, backed by ISO9001/AS9100 accreditation and full batch traceability.

- Perlast® seals have been used in place of Kalrez® and Chemraz® for many years in critical applications.

- Compliant with FDA, USP Class VI, BfR, 3A 18-03, EC1935/2004, EC2023/2006, BAM, NORSOK, TOTAL, NACE, ISO10423, ISO23936-2

Universal Chemical Resistance

- A molecular structure very similar to PTFE.

- Perlast® perfluoroelastomers are resistant to almost all chemical media.

- Perlast® food/pharma grades are resistant to steam, amines and solvents – ideal for withstanding SIP and CIP cleaning regimes.

- Other Perlast® grades are resistant to acids and hydrocarbons, designed to perform in CPI and Oil & Gas applications.

Applications of Perlast® FFKM:

Perlast® material grades are engineered to perform to the highest standard under the temperatures, pressures, chemical media considerations and mechanical stresses of the following applications:

- Pumps & Valves

- Quick Connectors / Break-away Couplings

- Hygienic/Sanitary Pipe Connectors

- Processing Equipment

- Hot Water / Steam Systems (CIP/SIP)

- Tank / Storage Systems

- Mechanical Seals

- Food & Pharma Manufacturing Equipment

- Biomedical Equipment & Instrumentation

- Subsea, Exploration, Drilling & Completion Equipment

- Downstream Refinery & Petrochem Equipment

- Compressors

“At Danco Industry, Perlast® material is the ultimate choice for our customers, where they face sealing challenges with extreme temperature and chemical compatibility.

This is a fantastic material and PPE has consistently exceeded our expectations in terms of quality and performance with it.

Having worked with PPE for over 10 years, we’ve found that their technical guidance and advice has been instrumental in helping us optimise processes and achieve optimal results for our customers.

Furthermore, PPE’s commitment to innovation and continuous improvement is evident in their product offerings and ongoing research and development efforts.

They have consistently stayed at the forefront of the industry, introducing new materials and technologies that meet and exceed industry standards.”

Vassil Vassilev

DANCO Industry

FFKM Material Comparison Table

Perlast® materials are compliant with the following industry standards:

Do you need an O-ring that can handle the most extreme industrial environments?

Perlast® elastomers are our highest-performing material grades, pairing exceptional reliability with proven performance. Our team will help you find the right solution for your application.

Discuss your application today

Please complete the form below and one of our experts will contact you.