Case Studies

Detailed below are some application stories based on recent projects.

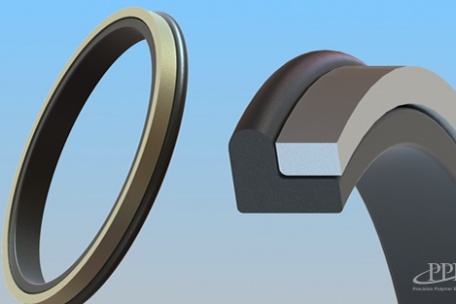

O-Rings manufactured and certified to order for defence application

Global manufacturer of specialist valves, instruments and related flow control products for Naval surface ships and submarines.

PPE seals reduce costs and improve patient experience

OEM of portable Haemodialysis machine required new seal design due to experiencing continual seal failure of Nitrile O-rings.

High performance seals help reduce marine engines maintenance costs

A world class manufacturer of gas engines for marine propulsion were in need of reducing maintenance costs and inventory.

Global Pharmaceutical Manufacturer Selects Perlast FDA Approved Seals

GlaxoSmithKline (GSK), one of the world's leading research-based pharmaceutical and healthcare companies undertook a review of seals on equipment used on a single Topicals filling and packaging lines.

Titanium processing plant needs exceptional seal quality and performance

Specialist metal processing facility carrying out melting and forging of titanium, required large O-rings that would not contaminate the molten titanium in the manufacturing process.

Critical Seals in FDA Approved Material for High Temperature Applications

Global manufacturer of safety valves for food and pharmaceutical valves required a white FDA-approved and USP-Class VI sealing solution that performed at 200 degrees.

High-low temp capability for jet engine seals

O-rings used in transmission system provide safety critical seals with both high and low temperature capability in jet engine.

PPE extends ED cycles and improves safety for high pressure compressors

HSE closure of three platforms due to gas leaks caused by OEM seal failure averted by switching to PPE's EnDura L-seals.

Low temp seals for semicon solvent storage tank

High purity FFKM seals used on outdoor solvent storage tanks meet low temperature requirements.

Rapid redesign of compressor seals for North Sea platform

Failed cord seal on gas platform is replaced with EnDura O-ring saving £1000s in lost production and increasing seal life performance.

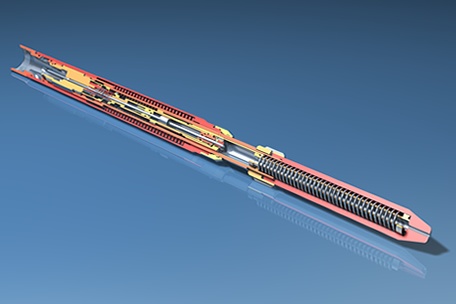

Red Spider goes deep with EnDura® ED resistant seals

Hydraulic RED is first to achieve ISO14310 V1 with EnDura O-ring seals

Authentic seal spec protects against poor performance

Oil leak in hose assembly leads to concerns about OEM seal spec. O-rings replaced and standardized with EnDura V91A for all valves on topside.

Cost savings for SECC stab connectors

PPE provides critical low temperature FFKM seals that ensure safety and environmental protection for disconnect valves in breakaway connectors.

Better seal performances leads to less downtime and lower operating costs

A leading manufacturer of marine engines were experience constant seal failure, costing £10,000 per day in downtime costs.

High Performance Seal Material Improves High Pressure Safety

Two 4-cylinder and four 6-cylinder HOS reciprocating compressors located on three offshore platforms were experiencing gas leaks, which caused major safety concerns.