Turbomachinery & Process Solutions (TPS)

Precision Polymer Engineering is your chosen Baker Hughes strategic supplier of elastomer seals for the Turbomachinery & Process Solutions (TPS).

Our relationship with Baker Hughes is built upon sharing elastomer technical expertise for over 10 years. We have worked with multiple companies that now form Baker Hughes and can offer you a proven track record in supplying ultra-reliable elastomer seals for applications like mechanical-drive and power generation, featured in industries from onshore and offshore production, liquefied natural gas, pipeline and gas processing, refinery and petrochemical systems.

Benefits:

- 24-hour technical support when and wherever you need it. From a phone call to a face-to-face meeting, we are here to provide you with the best in class technical support.

- Time saved sourcing seals for your project, with dedicated elastomer team here to advise you on which material and seal geometry will match your project requirements.

- Reduce cost of ownership through purchasing high quality, advanced elastomers seals that last longer in application, and minimise the risk of equipment downtime and maintenance intervals.

- Elastomer materials are approved to Baker Hughes specifications as well as being tested to the oil & gas industry standards, so you can feel confident in our products safety and manufacturing quality.

With an aim to help you reduce costs and downtime, we draw on our 25+ years of experience in manufacturing high performance elastomer seals to develop new and exclusive materials for Baker Hughes. A portfolio of projects showcases our expertise in finding sealing solutions for heavy-duty and aeroderivative machinery, such as gas and steam turbines, as well as reciprocating and centrifugal compressors.

When specifying Precision Polymer Engineering elastomer seals, you can be confident in protecting and improving the performance, availability and reliability of your rotating and static equipment over the entire lifecycle.

-

Typical Applications

- Gas and steam turbines

- Reciprocating and centrifugal compressors

-

Our Services

With no two projects alike, we aim to support you with our in-depth understanding of how different elastomer materials behave in offshore environments. We will leverage our skills in FEA simulation technology, CAD design, advanced laboratory testing and the latest in manufacturing techniques, to provide you with the highest quality sealing components. This level of advanced elastomer engineering support makes the difference between satisfactory and exceptional results.

- Dedicated Account Manager - Diego Bolanos

- Dedicated Product Manager - Steve Hindmarsh

- Finite Element Analysis

- Hardware design

- Custom seal design

- New elastomer materials formulated for specific requirements

- Laboratory testing and analysis

- Personalised training courses

- Improved manufacturing lead-times to meet Baker Hughes project deadlines

-

TPS Sealing Products

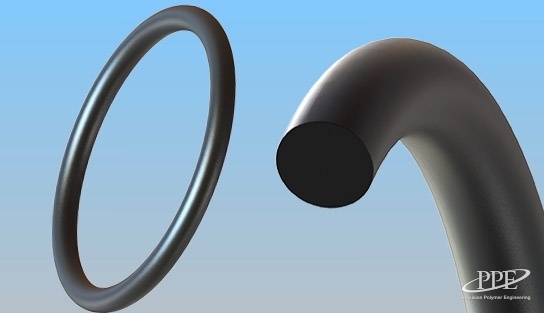

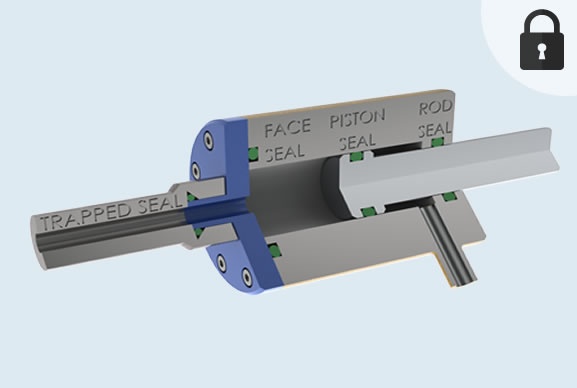

O-rings are the most common sealing product supplied to your Turbomachinery & Process Solutions sector. However, we can mould infinite seal geometries, with profiles and sizes to suit your given oil & gas application.

Our custom-engineered TPS seals are manufactured to fit the exact requirements of your hardware, protecting against explosive decompression (ED), sour gas (H2S) and the aggressive chemicals associated with oilfield media. This includes chemicals used to aid extraction of produced fluids through extension processes.

-

Elastomer Materials

From HNBR to FKM material grades, our innovative range of elastomer materials improve seal performance and reliability, with service life expectancy in excess of 25 years – even in the temperature and pressure extremes associated with upstream operations.

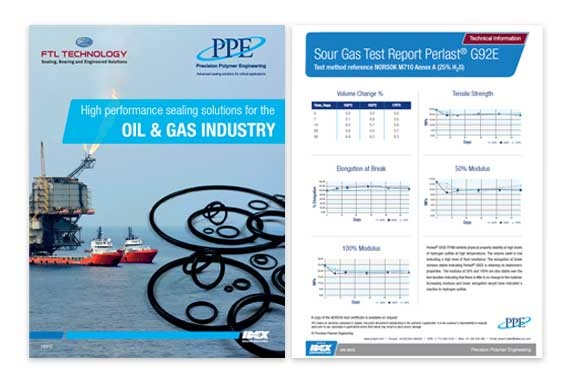

Our TPS elastomer materials are often not comparable to others on the market, because ours are extensively tested to international standards such as NORSOK, TOTAL, NACE, ISO 10423, API 6A/6D and ISO 23936-2.

Our Oil & Gas elastomer materials are compliant with:

.jpg)

Ask a question

How might we be able to help you?

Seals for Baker Hughes Turbomachinery & Process Solutions

Below is a selection of the most common products we supply to the Baker Hughes Turbomachinery & Process Solutions sector. Click on a specific product to find out further information.

Resources for Baker Hughes Turbomachinery & Process Solutions

All the relevant resources for the Turbomachinery & Process Solutions sector.

Engineers Hub Tools

The Engineers Hub has a host of online tools to help you with your seal selection.