Resources for Baker Hughes Oilfield Equipment

Click on the title of interest to expand the list of resources.

To minimise the list, simply click on the title again.

-

Material Media Compatibility

Key: 1 = Excellent, 2 = Good, 3 = Doubtful, 4 = Do not use

PPE Grade EnDura® A90H EnDura® V91K EnDura® V91A Perlast® G90LT Perlast® G92E EnDura® Z85L EnDura® Z95X Material Type FEPM FKM FKM FFKM FFKM HNBR HNBR Acid Mineral 1 1 1 1 1 3 3 Organic 3 2 2 1 1 2 2 Ammonia 2 4 4 1 1 1 1 Amines 2 4 4 1 1 1 1 Benzene 3 1 1 1 1 4 4 Bromide 1 1 1 1 1 3 3 Carbon Dioxide (CO2) 1 1 1 1 1 1 1 Brayco 864 1 1 1 1 1 1 1 Corrosion Inhibitors 1 3 3 1 1 1 1 Diesel 1 1 1 1 1 1 1 Erifon 818 or 818TLP - ASK PPE ASK PPE 1 1 1 1 Ethyl benzene 2 1 1 1 1 4 4 Formates 2 3 3 1 1 4 4 Gas N2 1 1 1 1 1 1 1 HCI 20% 1 1 1 1 1 3 3 Heavy Fuel Oils 3 1 1 1 1 1 1 Hydrocarbon Gases 2 1 1 1 1 1 1 Hydrocarbon Oils 2 1 1 1 1 1 1 IRM 903 2 1 1 1 1 1 1 Kerosene 2 1 1 1 1 2 2 Lubricants 2 1 1 1 1 1 1 Oceanic HW 740R - - - 1 1 1 1 Oceanic HW525 - - - 1 1 1 1 Oceanic HW443 - - - 1 1 1 1 Methane 2 1 1 1 1 1 1 Methanol 1 3 2 1 1 1 1 Mono Ethylene Glycol 1 1 1 1 1 1 1 NaOH 10% 1 3 3 1 1 1 1 Oil & Water Emulsions 2 1 1 1 1 1 1 Polyalkylene glycols 1 1 1 1 1 1 1 Sea Water 1 1 1 1 1 1 1 Sour Gas (H2S) < 2% 3 1 1 1 1 1 1 > 2% 3 1 1 1 1 2 2 < 30% 3 2 2 1 1 3 3 > 30% 3 2 2 1 1 4 4 Steam 1 1 1 1 1 1 1 Xylenes 3 1 1 1 1 4 4 -

Material Operating Limits

PPE Grade Material Type Description TR10 °C / °F Tg °C / °F Operating Temperature (°C) (°F) EnDura® A90H FEPM Aflas® based copolymer - 0 / +32 0 to +250 +32 to +482 Perlast® G90LT FFKM Low temperature grade -31 / -24 -30 / -22 -46 to +240 -51 to +464 Perlast® G92E FFKM RGD & chemical resistant grade -8 / +18 -7 / +19 -15 to +260 +5 to +500 EnDura® V91A FKM Ultra-low temperature grade -46 / -51 -44 / -47 -51 to +225 -60 to +437 EnDura® V91K FKM Low temperature grade -35 / -31 -35 / -31 -41 to +225 -42 to +437 EnDura® Z85L HNBR Low temperature grade -46 / -51 -50 to +160 -58 to +320 EnDura® Z95X HNBR General purpose grade - -27 / -17 -29 to +180 -20 to +356 As materials cool they become steadily stiffer, ultimately becoming glassy and brittle. TR10 (ASTM D1329) and Tg (ASTM D7426) seek to give guidance as to when this occurs. Sealing has been shown to be possible below this temperature; which is reflected in part in the lower operating limit. The change to a glassy state is completely reversible, unlike the degradation that takes place at elevated temperatures. All seals have a finite life, the upper operating limit seeks to give a guide as to the point at which an appreciable life can be attained. Neither of these temperatures are absolute limits and short-term excursions are possible above the upper limit and in some situations sealing is possible below the lower limit; in certain cases far below.

EnDura® and Perlast® are registered trademarks of Precision Polymer Engineering.

Aflas® is a trademark of the Asahi Glass Company. -

RGD Material Test Data

PPE Material Grade Material

TypeDescription NORSOK

M710ISO

23936-2NACE

TM0297TOTAL

GSPVV142Shell

SPE 85/301Aramco

06-SAMSS-001EnDura® A90H FEPM Aflas based copolymer Pass Pass Pass Pass Not tested Pass Perlast® G90LT FFKM Low temperature grade Pass Pass Pass Pass Not tested Not tested Perlast® G92E FFKM RGD & chemical resistant grade Not tested Not tested Pass Pass Not tested Not tested EnDura® V91A FKM Ultra-low temperature grade Pass Pass Pass Pass Not tested Not tested EnDura® V91K FKM Low temperature grade Pass Pass Pass Pass Pass Pass EnDura® Z85L HNBR Low temperature grade Not tested Not tested Pass Not tested Not tested Not tested EnDura® Z95X HNBR General purpose grade Pass Pass Pass Pass Not tested Not tested Comparison of RGD test parameters:

NORSOK

M710ISO

23936-2NACE

TM0297TOTAL

GSPVV142Shell MESC

SPE 85/301Aramco

06-SAMSS-001Specimen ISO3601 -325

O-ringISO3601 -312

O-ring or largerISO3601 -325

O-ringISO3601 -349

or -425 O-ringISO3601 -325

O-ringISO3601 -325

O-ringConstraint 20% compression 14.5% compression Optimal 13.5% compression Optimal 14.2% compression Replication Three Four Nine Three Four Four Gas % 90/10 CH4/CO2 90/10 CH4/CO2 100% CO2 80/20 CH4/CO2 90/10 CH4/CO2 95/5 CH4/CO2 Temperature 100°C 100°C 120°C 75°C 150°C 100°C Pressure 15 MPa 15 Mpa 7 MPa 19 MPa 15 MPa 14 MPa Initial soak period 72 hours 68 hours -- 78 hours 72 hours 48 hours Soak period 24 hours 6 and 12 hours

alternating24 hours 48 hours 6 hours minimum 1 hour Decompression rate 3 MPa/min 2 MPa/min 7 MPa/min 19 to 0 MPa

in 90 secs2 MPa/min 7 MPa/min Dwell at ambient pressure 1 hour 1 hour -- 1 hour 1 hour -- Cycles 10 8 1 5 8 5 -

Sour Gas Material Test Data

PPE Material Grade Material

TypeDescription NORSOK M710

2%NORSOK M710

25%NACE TM0187 ISO 10423

(API FF/HH)EnDura® A90H FEPM Aflas based copolymer Tested* Tested* Not tested Tested* Perlast® G90LT FFKM Low temperature grade Pass Tested* Not tested Pass Perlast® G92E FFKM RGD & chemical resistant grade Pass Tested* Not tested Pass EnDura® V91A FKM Ultra-low temperature grade Pass Tested* Pass Pass EnDura® V91K FKM Low temperature grade Pass Tested* Pass Pass EnDura® Z85L HNBR Low temperature grade Not tested Tested* Not tested Pass EnDura® Z95X HNBR General purpose grade Pass Not tested Pass Pass *Contact PPE for further details

Comparison of sour (H2S) test parameters:

NORSOK

M710

2%NORSOK

M710

25%NACE TM0187 ISO 10423

(API FF/HH)Test vessel composition:

Gas phase

Oil phase

Water phase

30%

60%

10%

30%

60%

10%

90%

5%

5%

35%

60%

5%Gas phase composition

Volume (%)2% H2S

3% CO2

95% CH425% H2S

3% CO2

72% CH4FKM

20% H2S

5% CO2

75% CH4HNBR

5% H2S

20% CO2

75% CH410% H2S

80% CO2

10% CH4Oil phase composition:

Volume (%)10% toluene

20% cyclohexane

70% heptane10% toluene

20% cyclohexane

70% heptane25% hexane

20% octane

50% decane

5% toluene100% kerosene Water phase composition:

Volume (%)100% distilled water 100% distilled water 100% ASTM S1193 Type IV 100% deionised water Test specimen location Oil phase Oil phase Gas phase Oil phase Temperature Various from 100°C to 200°C Various from 150°C to 175°C 150°C (FKM)

100°C (HNBR)177°C Test duration 8 weeks 8 weeks 160 hours 160 hours

-

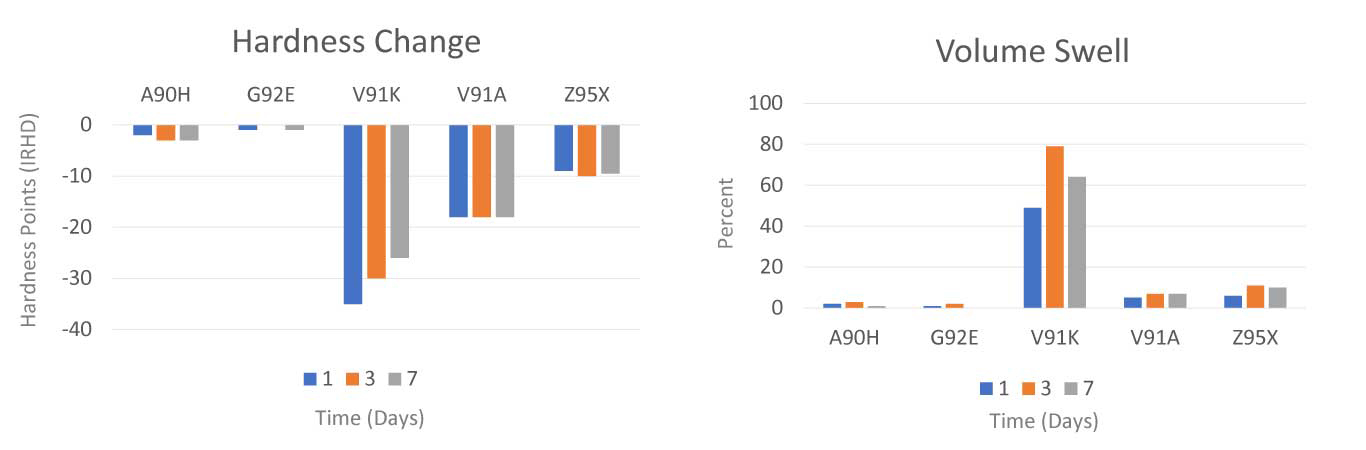

Methanol Immersion Material Test Data

Test Conditions

Five elastomer grades; A90H, G92E, V91K, V91A and Z95X were tested in 100% methanol.The test used BS1806-312 size O-rings. Test conditions were room temperature for 168 hours, with sampling intervals at 24hrs and 72hrs.

Test Procedure

- Specimens of each material were immersed in methanol liquid under ambient conditions.

- Volume was measured as per ASTM D297, and hardness as per ASTM D1414/1415; before immersion, at each interval and after 7 days immersion.

- Hardness change in points and volume change in percent was calculated as per ASTM D471.

Property Time (Days) A90H G92E V91K V91A Z95X Hardness Point Change IRHD 1 -2 -1 -35 -18 -9 3 -3 0 -30 -18 -10 7 -3 -1 -26 -18 -9.5 Volume Swell % 1 2 1 49 5 6 3 3 2 79 7 11 7 1 0 64 7 10

-

RGD Test Certificates

Test certificates to Rapid Gas Decompression (RGD) standards.

Title Description Downloads NACE Certificates Perlast® G92E NACE TM0297 certificate of RGD testing View Certificate Perlast® ICE G90LT NACE TM0297 certificate of RGD testing View Certificate EnDura® Z85L NACE TM0297 certificate of RGD testing View Certificate EnDura® Z95X NACE TM0297 certificate of RGD testing View Certificate EnDura® V91A NACE TM0297 certificate of RGD testing View Certificate EnDura® V91K NACE TM0297 certificate of RGD testing View Certificate EnDura® A90H NACE TM0297 certificate of RGD testing View Certificate NORSOK Certificates Perlast ICE® G90LT NORSOK M-710 Rev.2, Section 7.3, Annex B certificate of RGD testing View Certificate EnDura® Z95X NORSOK M-710 Rev.2, Section 7.3, Annex B certificate of RGD testing View Certificate EnDura® V91A NORSOK M-710 Rev.2, Section 7.3, Annex B certificate of RGD testing View Certificate EnDura® V91K NORSOK M-710 Rev.2, Section 7.3, Annex B certificate of RGD testing View Certificate EnDura® A90H NORSOK M-710 Rev.2, Section 7.3, Annex B certificate of RGD testing View Certificate TOTAL Certificates Perlast® G92E TOTAL General Specification GS EP PVV 142 Rev 09 certificate of RGD testing View Certificate Perlast ICE® G90LT TOTAL General Specification GS EP PVV 142 Rev 09 certificate of RGD testing View Certificate EnDura® Z95X TOTAL General Specification GS EP PVV 142 Rev 09 certificate of RGD testing View Certificate EnDura® V91A TOTAL General Specification GS EP PVV 142 Rev 09 certificate of RGD testing View Certificate EnDura® V91K TOTAL General Specification GS EP PVV 142 Rev 09 certificate of RGD testing View Certificate EnDura® A90H TOTAL General Specification GS EP PVV 142 Rev 09 certificate of RGD testing View Certificate ISO 23936-2 Certificates EnDura® V91K ISO 23936-2 certificate of RGD testing View Certificate EnDura® V91A ISO 23936-2 certificate of RGD testing View Certificate EnDura® A90H ISO 23936-2 certificate of RGD testing View Certificate EnDura® Z95X ISO 23936-2 certificate of RGD testing View Certificate Shell Certificate EnDura® V91K Shell SPE 85/301 certificate of RGD testing View Certificate Aramco Certificates EnDura® V91K Aramco 06-SAMSS-001 certificate of RGD testing View Certificate EnDura® A90H Aramco 06-SAMSS-001 certificate of RGD testing View Certificate -

H2S Test Certificates

Test certificates to sour gas test standards.

Title Description Download NORSOK Certificates Perlast® G92E NORSOK M-710 Rev.2, Annex A certificate of H2S testing View Certificate Perlast ICE® G90LT NORSOK M-710 Rev.2, Annex A certificate of H2S testing View Certificate EnDura® V91A NORSOK M-710 Rev.2, Annex A certificate of H2S testing View Certificate EnDura® V91K NORSOK M-710 Rev.2, Annex A certificate of H2S testing View Certificate Custom H2S Test Certificates Perlast® G92E Certificate of custom testing at 25% H2S View Certificate Perlast ICE® G90LT Certificate of custom testing at 25% H2S View Certificate EnDura® V91K Certificate of custom testing at 25% H2S View Certificate -

Brochures

Title Description Download Corporate Brochure An introduction to PPE International LLC, our product range and commitment to the KSA View Brochure Sealing Solutions for Oil & Gas An overview of the products and services available from PPE for the oil & gas industry View Brochure Explosive Decompression Resistant Elastomers A summary of international ED test standards (NORSOK, TOTAL, NACE & ISO23936) plus details of which PPE materials meet each standard. View Brochure Sour Gas Resistant Elastomers A summary of international H2S test standards (NORSOK, API 6A & ISO10423) and details of which PPE materials have been tested and certified. View Brochure Perlast® An overview of the various products, applications and benefits of using Perlast® perfluoroelastomers in the oil and gas industry. View Brochure Perlast ICE® The ultimate perfluoroelastomers for sealing applications where chemical resistance and extreme low temperature performance are critical. View Brochure EnDura® The ultimate range of elastomers for sealing applications in the World's most aggressive high pressure environments. View Brochure Spring Seals and FS Seals Spring seals and FS Seals for use on oilfield equipment operating in extreme high pressures and aggressive chemicals. View Brochure

Oil & Gas Case Studies

Take a look at our selection of customer stories from the Oil and Gas sector. To find out more about what we've done in this industry in the recent past, get in touch with an engineer today.

Ask a question

Tell us what resources you are looking for and we will aim to get back to you within 24 hours.